N

‐

i

‐

HP

Inverter

air

/

water

heat

pump

chillers

with

axial

fans

5

4

GENERAL

SAFETY

GUIDELINES

Before

beginning

to

operate

on

N

‐

i

‐

HP

units

every

user

has

to

be

perfectly

knowledgeable

about

the

functions

of

the

equipment

and

its

controls

and

has

to

have

read

and

understood

the

information

listed

in

this

manual.

It’s

strictly

forbidden

to

remove

and/or

tamper

with

any

safety

device.

Children

or

unassisted

disabled

persons

are

not

allowed

to

use

the

appliance.

Do

not

touch

the

appliance

when

barefoot or

parts

of

the

body are

wet

or

damp.

Do

not

pull,

remove

or

twist

the

electrical

cables

coming

out

from

the

unit,

even

if

it

is

disconnected

from

the

main

power

supply.

Do

not

step

with

your

feet

on

the

appliance,

sit

down

and/or

place

any

type

of

object.

Do

not

spray

or

pour

water

directly

on

the

unit.

Do

not

dispose

of,

abandon

or

leave

within

reach

of

children

packaging

materials

(cardboard,

staples,

plastic

bags,

etc)

as

they

may

represent

a

hazard.

Any

routine

or

not

‐

routine

maintenance

operation

shall

be

carried

out

when

the

equipment

has

been

shut

down,

disconnected

from

electric

power

sources.

Do

not

put

neither

your

hands

nor

insert

screwdrivers,

spanners

or

other

tools

into

moving

parts

of

the

equipment.

The

equipment

supervisor

and

the

maintenance

man

has

to

receive

suitable

training

for

the

performance

of

their

tasks

in

safety.

Operators

have

to

know

how

to

use

personal

protective

devices

and

have

to

know

the

accident

‐

prevention

guidelines

contained

in

national

and

international

laws

and

norms.

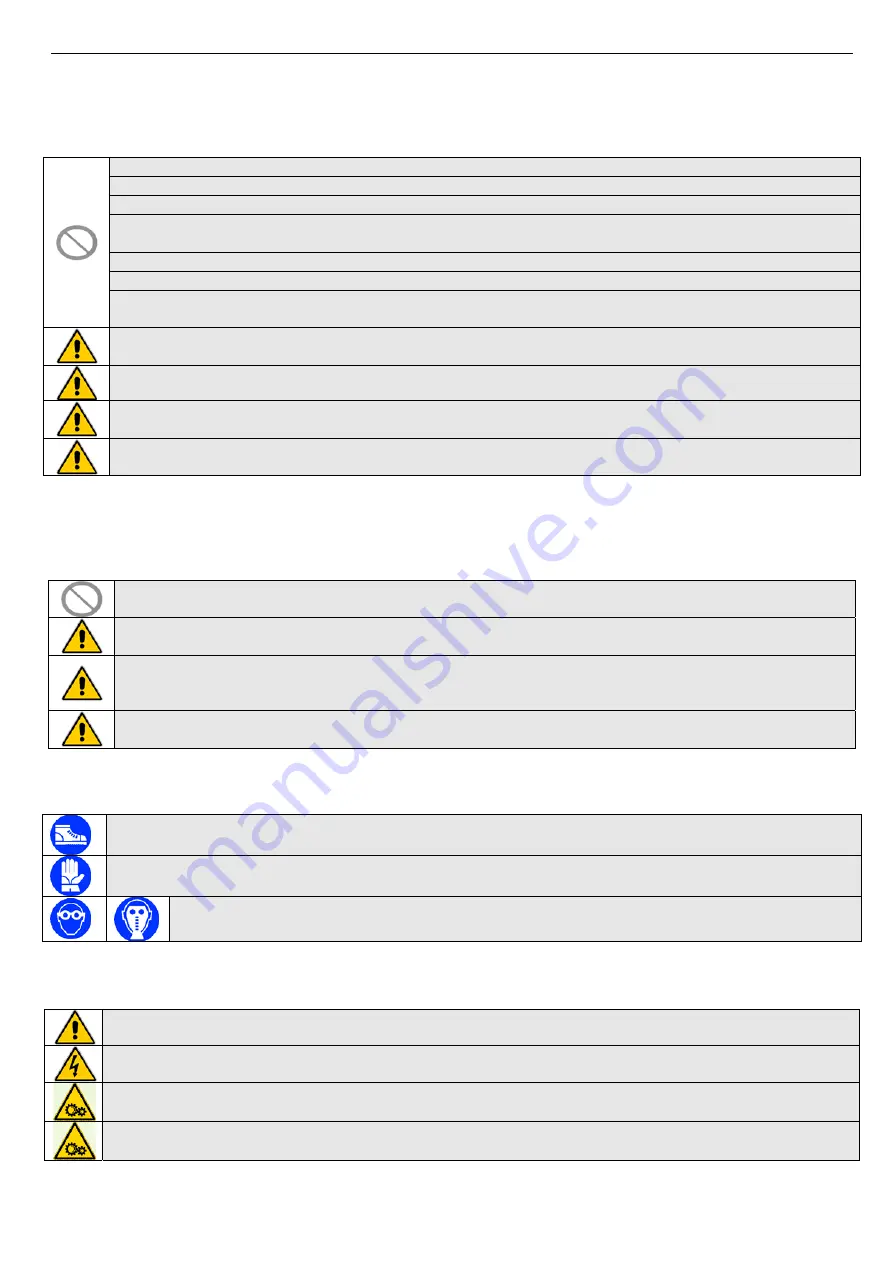

4.1

WORKERS’

HEALTH

AND

SAFETY

The

European

Community

has

adopted

a

number

of

directives

on

workplace’s

health

and

safety,

including

89/391/CEE

,

89/686/CEE,

89/655/CEE,

86/188/CEE

and

77/576/CEE

directives.

Every

employer

shall

implement

such

norms

and

ensure

that

workers

to

respect

them.

It

points

out

that:

Do

not

tamper

with

or

replace

parts

of

the

equipment

without

the

specific

consent

of

the

manufacturer.

The

manufacturer

shall

have

no

responsibility

whatsoever

in

case

of

unauthorised

operations.

Using

components,

expendable

materials

or

spare

parts

that

do

not

correspond

to

those

recommended

by

the

manufacturer

and/or

listed

in

this

manual

may

be

dangerous

for

the

operators

and/or

damage

the

equipment

The

operator’s

workplace

has

to

be

kept

clean,

tidy

and

free

from

objects

that

may

prevent

free

movements.

Appropriate

lighting

of

the

work

place

shall

be

provided

so

as

to

allow

the

operator

to

carry

out

the

required

operations

safely.

Poor

or

too

strong

lighting

can

cause

risks.

Ensure

that

work

places

are

always

adequately

ventilated

and

that

aspirators

are

working,

in

good

condition

and

in

compliance

with

the

requirements

of

the

laws

in

force.

4.2

PERSONAL

SAFETY

EQUIPMENTS

When

operating

and

maintaining

the

N

‐

i

‐

HP

units,

use

the

following

personal

protective

equipments.

Protective

clothing:

Maintenance

men

and

operators

has

to

wear

protective

clothing

that

complies

with

the

basic

safety

requirements

currently

in

force.

In

case

of

slippery

floors,

users

have

to

wear

safety

shoes

with

non

‐

slip

soles.

Gloves:

During

maintenance

or

cleaning

operation

protection

gloves

have

to

be

used

Mask

and

goggles:

Respiratory

protection

(mask)

and

eye

protection

(goggles)

should

be

used

during

cleaning

and

maintenance

operations.

4.3

SAFETY

SYMBOLS

The

unit

features

the

following

safety

signs,

which

has

to

be

complied

with:

General

hazards

Electric

shock

hazard

Presence

of

moving

organs

Presence

of

surfaces

that

may

cause

injures