MENUS: 1Y.5 HARDWARE

7 - 17

D-MAXE with OI-TS

www.maxcessintl.com

MI 2-292 1 C

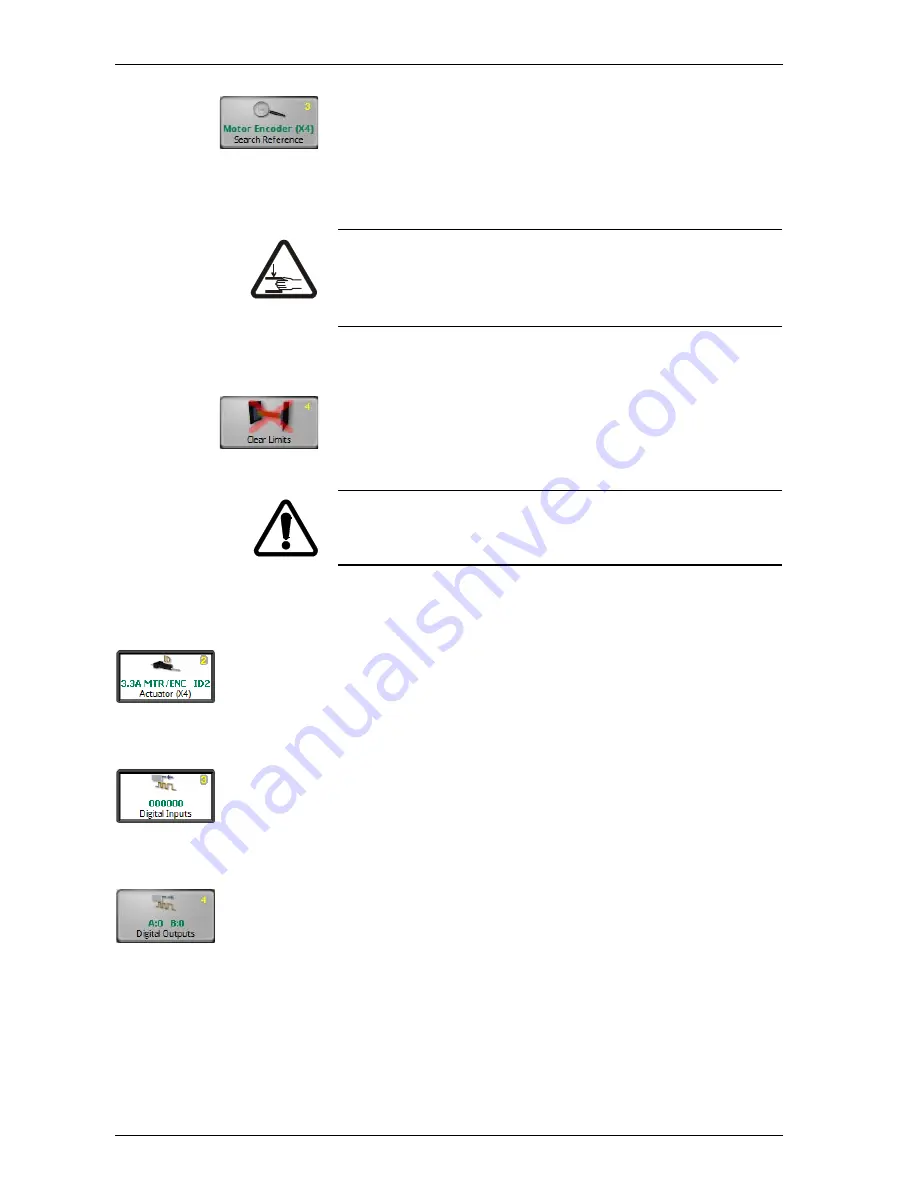

1y.5.1._.3 Search Reference

You can use the

Search Reference

menu to recover lost

thresholds without having to perform a calibration again. Limit

values can be lost for example because the encoder was

adjusted with the electrical power turned off.

WARNING:

The drive moves while the reference search is active.

The actuator poses a crushing hazard.

1y.5.1._.4 Clear Limits

You can use the

Clear Limits

menu to delete limits that are

present for the selected encoder.

CAUTION:

Deleting the encoder limits may result in additional danger of

crushing or could damage the mechanical stops.

1y.5.2 Actuator

Shows the motor that is connected to the selected drive (see

table on page

1y.5.3 Digital Inputs

Display of the 6 digital inputs

1y.5.4 Digital Outputs

Configuration of the physical properties of digital outputs A and

B