www.maxcessintl.com

HEB250 Brake

MI 850A346 1 B

Page 15

Replacement Part Kits:

Pad replacement kits.

Each kit contains (2) ea pads to fill (1) ea caliper.

Model Number

Description

HEBPKL

HEB pad kit for low friction pads (0.21)

HEBPKM

HEB pad kit for medium friction pads (0.41)

HEBPKH

HEB pad kit for high friction pads (0.51)

Replacement Calipers

. Each kit contains a front and back caliper half. (Note: brake pad(s) are NOT included.)

Model Number: HEBCALREPL

Caliper Rebuild kit

. Each kit contains seals, bearing strips, and o-rings which will rebuild both the front and back

caliper half.

Model Number: RKHEBCAL

Replacement Rotor kit

. Add the appropriate 2 digit bore core from table 1 to the end of the model number.

Model Number: HEB250RTR

– xx

Adapter Plate.

HEB250BKPLT

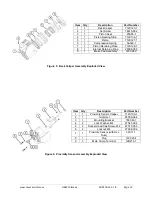

Exploded views of the caliper assemblies:

Item Qty

Description

Part Number

1

1

Front Caliper

712C125-1

2

1

Set Screw

78610-002

3

1

Piston Seal

25A65-1

4

1

Piston Bearing Strip

712C134-1

5

1

Piston

712C127-1

6

1

Compression Spring

5A349-1

7

1

Piston Retaining Plate

712C128-1

8

1

Internal Retaining Ring

28098-059

9

1

Brake Pad Assembly

145C24-X

10

1

Pneumatic Fitting (Tee)

5C344-2

10

1

Pneumatic Fitting (90 Deg)

5C347-2

Figure 4. Front Caliper Assembly Exploded View