6.0 TENSION CONTROL

www.maxcessintl.com

MAGPOWR Spyder-Plus-S1 Tension Control

MI 850A351 1 C

Page 16 of 68

6.2.2.1

CONTROL TYPE

Select the

Load Cell

control type. Load cell systems must use a torque device, which can be a motor in torque

mode.

6.2.2.2

SYSTEM TYPE

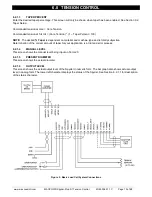

Select the appropriate system type for the application; rewind, unwind, or one of the point-to-point types. See

Figure 6 for information on the point-to-point types.

6.2.2.3

DIAMETER USED

Select the diameter type either estimated or an external voltage proportional to diameter. For calibrating diameter

see section 6.5 if diameter type is

Voltage

and section 9.2 if diameter type is

Estimated

.

6.2.2.4

INERTIA COMPENSATION USED

Select whether inertia compensation is used during stopping. This helps to keep the tension constant during

stopping. See section 6.6 on setting up and using inertia compensation.

6.2.2.5

HOLD LEVEL CHANGE WITH

Hold Level Output during Hold mode can be a fixed value, or can vary with last running output multiplied by the

Hold Level Multiplier, or can vary based on diameter and or tension. Select the choice needed for the application;

None, Output, Diameter, Tension, or Diameter and Tension. See section 9.6.13 to calibrate hold level changes

when the choice is Diameter, Tension, or Diameter and Tension. See section 9.6.14 to enter the Hold level

multiplier when the choice is Output.

6.2.2.6

OUTPUT RANGE

Select the main output range. For a main output range of either 0-10 VDC or 4-20 mADC select

NORMAL

. For the

–10 to +10 VDC range, select

–10 V to +10 V

. The software is factory calibrated for the 0-10 VDC and the -10 to

+10 VDC output ranges. See Section 9.4 for recalibrating the output when using the 4-20 mADC range.

See Figure 4 for jumper settings.

6.2.2 CONFIGURE MENU

Navigate to the

Configure

menu. Press

. This section describes all

the screens in the Configure menu. This menu contains screens which

configure various options.

Summary of Contents for MAGPOWR Spyder-Plus-S1

Page 2: ......