6.0 TENSION CONTROL

www.maxcessintl.com

MAGPOWR Spyder-Plus-S1 Tension Control

MI 850A351 1 C

Page 21 of 68

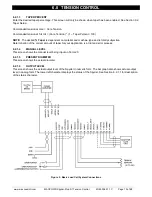

6.6 INERTIA COMPENSATION

The

Inertia Set-up

menu is used to configure and calibrate inertia.

The parameters in these screens apply to a full roll of web material.

Roll weight

is the weight of a full roll of web material.

Full roll

diameter is the diameter of the full roll of web material.

Roll width

is the width of the full roll of web material. This is only for calibration. For

rolls with other widths there is a screen in the parameters menu to enter the present

web width.

Core diameter

is the diameter of the core.

Core WK^2

is the inertia of the core. The units for inertia are either lb-ft^2 or kg-

m^2. The selection depends on the units for tension.

Run the system, and when the system is stable, select

Cal Inertia

to be

Yes

and

press

key to calibrate output versus torque. Any diameter roll of material may be

used when calibrating the output versus torque.

Diameter and Tension must be calibrated before calibrating inertia.

There are two parameters in the Parameters menu to set the maximum line speed

and the present roll width. See sections 9.6.9 and 9.6.10. The inertia compensation

is computed for slowing down the roll from maximum line speed to zero in the stop

time.

If the web material changes then the roll weight, full roll diameter and roll width

parameters will need to be changed in the Inertia Set-up menu. If the core diameter

changes or the core changes material then the Core Inertia and Core Diameter

parameters must be changed in the Inertia Set-up menu. The calibration for output

versus torque does not need to be calibrated again.

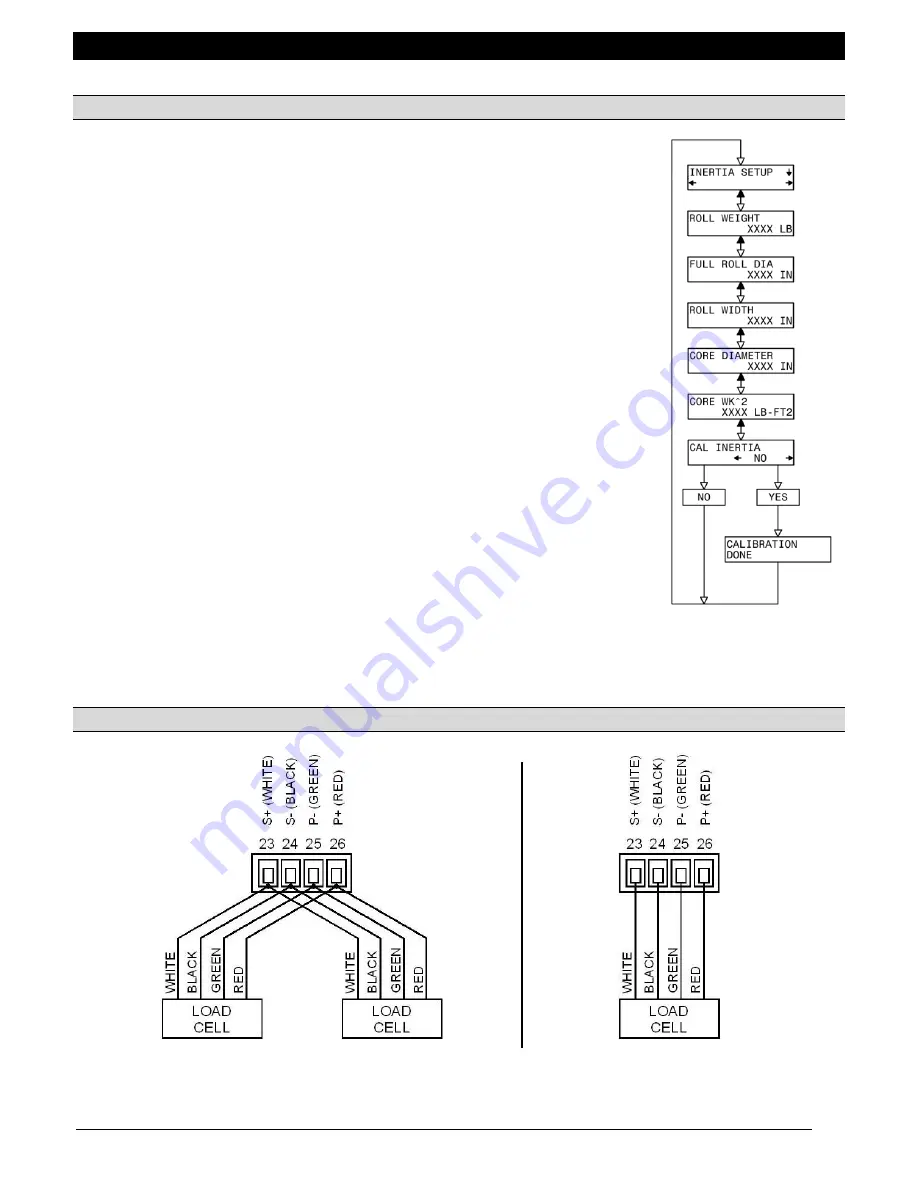

6.7 LOAD CELL CONNECTIONS

Figure 8. Load Cell Connections for One or Two Load Cells

Summary of Contents for MAGPOWR Spyder-Plus-S1

Page 2: ......