7.0 DANCER CONTROL

www.maxcessintl.com

MAGPOWR Spyder-Plus-S1 Tension Control

MI 850A351 1 C

Page 32 of 68

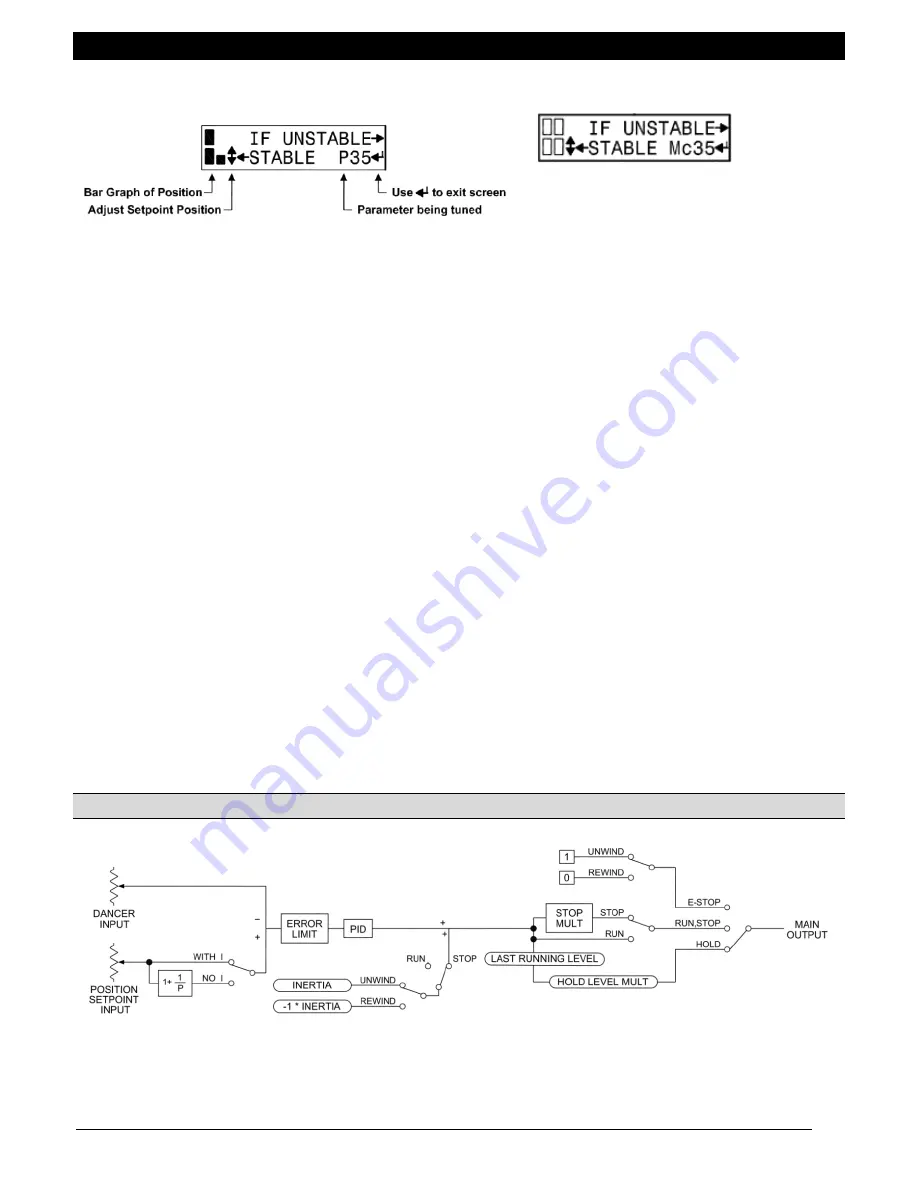

7.6.1

TUNING SCREENS

Press the up or down button to reposition the dancer if necessary. The analog position setpoint is not active during

tuning, but is an internal software parameter. In these screens there is number next to the parameter being tuned

which is not the value of the parameter, but shows the progress of tuning. Its value can be between 00 and 99. 00

is displayed when a parameter is as stable as it can be. Press the

key until the system is stable. Press the

key until the system starts to become unstable. Then press the

key until stability is regained. When finished

tuning press

to exit the screen.

NOTE:

Applies to Setpoint Source is Analog. The position setpoint input is not active during tuning. The

and

keys are used to change dancer position instead. For this reason, the web must be stopped (Run/Stop = Stop) and

restarted (Run/Stop = Run) to leave the tuning screens. A screen is provided to warn the operator of this. Since

tuning cannot be done while the web is stopped, the Spyder automatically returns to the

Tuning Menu when the web is stopped. Make sure to set the position setpoint potentiometer to the midpoint before

restarting after tuning.

NOTE:

Applies to Setpoint Source is Ethernet. The position setpoint can always be changed during tuning either

by Ethernet or by the

and

keys. The dancer does not need to be stopped to exit the Tuning screens.

Since the controller gain is a product of proportional gain and a function of the diameter ratio (present diameter / full

diameter) at small diameters there may not be enough gain to correct for position errors. The stop torque ratio, Mc,

is essentially a gain offset near core. Tune this parameter near core. Since this affects controller gain it may be

necessary to retune proportional gain at full roll if the control is now unstable at full roll after tuning Mc at core. If

while running from full roll to core for the first time and the control does not have enough gain to make position

corrections, it may be necessary to tune stop torque ratio, Mc, before core is reached.

Stop torque ratio, Mc, provides a control gain offset near core diameter and is used to provide enough gain at core

diameter to correct for position changes.

There is a table in section 9.6.6 showing default values of proportional, integrator, derivative, error limit and stop

torque ratio for each type control type.

7.7 CONTROL DIAGRAM

– DANCER, TORQUE WITH NO DIAMETER

Figure 13. Dancer, Torque with No Diameter Control Diagram

Summary of Contents for MAGPOWR Spyder-Plus-S1

Page 2: ......