COMMISSIONING OF DP-20/DP-30

3 - 3

SE-46C

Commissioning of the web guide controllers

www.maxcess.eu

MI 1071 1 A

OI-TS operator interface:

∙

Select signal assignment 10mA

DP-20/DP-30 web guide controller:

∙

Determine the second reference value

∙

Press the ENTER key

The DP-20/DP-30 web guide controller returns to the user area

if the calibration was successful.

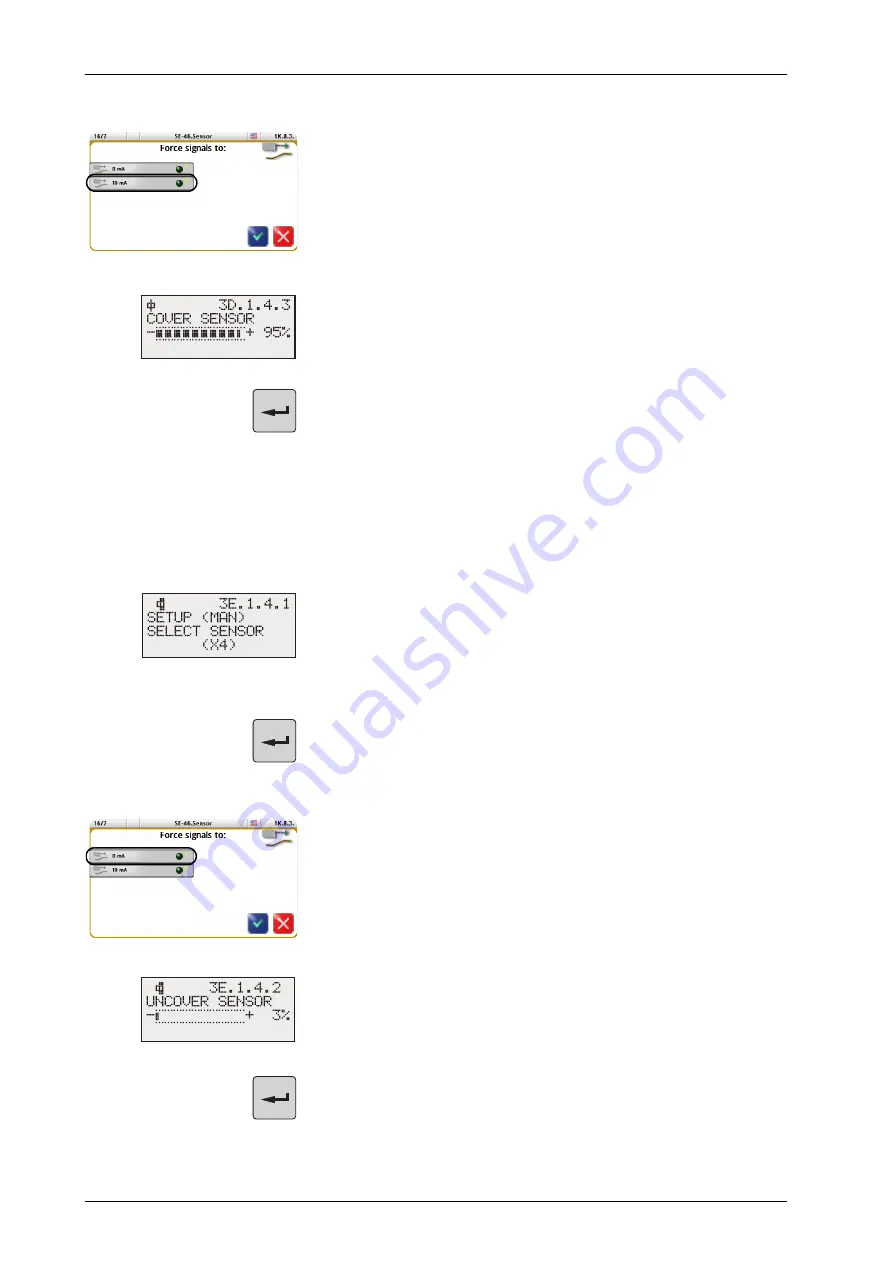

1.4. Calibrating the locking

signal on the DP-20/DP-30

DP-20/DP-30 web guide controller:

∙

Select menu 3E.1.4.1

Select Sensor

(Manual

Basic

Calibration

Select Sensor)

∙

DP-20 controller:

select

(X4)

DP-30 controller:

select

(X5)

(line sensor - print or material edge

§

)

∙

Press the ENTER key

OI-TS operator interface:

∙

Select signal assignment 0mA

DP-20/DP-30 web guide controller:

∙

Determine the first reference value

∙

Press the ENTER key

G

G

G