RMT55H

20195 South Diamond Lake Road, STE 100

Rogers, MN 55374

800.621-2789

28

7

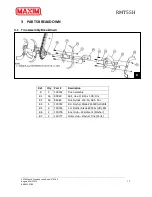

ADJUSTMENTS

7.1

Clutch Adjustment

Proper clutch adjust is very important. Minor adjustment, if needed, can be made by using the

links on the clutch cable chain only. However, the friction type clutch may need further

adjustments as the “V” belt wears. Adjust as follows:

1.

Remove belt guard.

2.

Loosen 4 engine mount bolts. Slide

engine forward or backwards as

required.

3.

Unhook clutch cable from load spring.

4.

Push upward on idler pulley to take all

slack from the drive belt. Distance

between the inside of belt at the idler

pulley should be between 2 7/8 and 3

1/8 of an inch.

5.

Ensure pulleys are aligned with a long

straight edge.

6.

Retighten engine mounting bolts (17 foot lbs. of torque).

7.

Remove all the slack from clutch cable and hook spring in proper chain link.

8.

Check your adjustment by starting the tiller and holding the tines off the ground. If the

tines turn without any hand pressure on the engage lever, the adjustment is too tight.

Unhook the clutch load and hook into next chain link to lengthen clutch cable. If the cable

spring on the clutch handle doesn’t stretch when you hold the clutch handle all the way

in, the adjustment is too loose. Unhook spring end from chain and hook next link to

shorten clutch cable.

7.2

Wheel Height Adjustment

1.

Wheel position may be adjusted. To place wheels in up position, pull the spring-loaded

locking pin from the wheel yoke and repositioning the wheel frame bar allowing the

spring-loaded pin to reposition and lock wheels in the up position. For weeding or

cultivation, wheels may be left down if you prefer.

⚠

DANGER

To avoid possible serious bodily injury, when performing any adjustments, remove the

spark plug wire and place the wire away from the plug to prevent accidental starting.