MAINTENANCE

PERIODIC CHECK

1. Regularly check all bolts and nuts for tightness.

2. If the belt begins to bottom out on the engine pulley, then replacement of the pulley is needed. This is

noticeable by the pulley “V” bottom becoming shiny.

BELT REPLACEMENT

The drive belt is located on the left side of the machine. To replace a worn or slipping belt proceed as fol-

lows.

1. Remove belt guard.

2. Make sure clutch lever is in disengaged position.

3. Start at the top of 9” or 7” pulley and begin removing belt in clockwise direction (facing tiller from the

left side). If tension on belt is too great the idler pulley may be pulled downward to relieve pressure on

belt.

4. Once belt is off 9” or 7” pulley remove it from smaller pulley.

5. Replace belt by reversing sequence of steps above.

6. Replace belt guard, “C” nuts, and thumb screws.

LUBRICATION

1. Wheels --

Lubricate wheels and wheel support shafts once a month or every 40 operating hours with

#30 oil. Apply oil to axle and hub at back of wheel. Spin wheel to allow oil to move into bearing. In ex-

tremely dusty conditions, wheels may become tight because of dust in bearing area. When this occurs,

remove the wheels and clean axle and wheel bearing surfaces with solvent or emery cloth. Oil and reas-

semble.

2. Throttle Control Cable

-- Lubricate control cable as necessary, with #30 oil. Apply with a saturated

rag or an oil can along the outer surface of the conduit. Remove excess oil.

3. Clutch Lever Pivots --

Apply a few drops of SAE 30 oil to the clutch hand lever and idler lever pivots

as required to maintain a free and smooth operation of clutch.

4. Transmission --

Fill transmission with machine in normal upright position. Fill plug is located on the

upper right hand side. Use 90 weight gear lube or 50 weight motor oil. Capacity is approximately 16

ounces. Remove fill plug. Remove check plug. Fill until check plug hole overflows. Replace plugs. If

excessive oil leakage appears around rotor shaft, the seals and shields must be replaced.

5. Idler Arm Pivots --

Lubricate idler arm pivots once a month or every 40 operating hours with #30 oil.

STORAGE --

At the end of the season or if the tiller is to be stored for any length of time it should be

washed. To make the job easier use a soft-bristled scrub brush to clean wheels and tires. A stick can be

used to clean dirt from crevices. This simple procedure will keep your tiller looking like new for years.

ENGINE MAINTENANCE AND STORAGE -- REFER TO ENGINE OWNER’S MANUAL FOR

PROPER STORAGE AND MAINTENANCE OF YOUR ENGINE.

PARTS BREAKDOWNS

TINES

MT AND TP MODELS

RMT MODELS

Ref

Part #

Quan

Description

Part #

Quan

Description

504

461466

4

Tine Pin

461466

4

Tine Pin

505

460312

4

Hair Pin

460312

4

Hair Pin, Cotter

508

130720

8

Bolo Blade, Right

130762

4

Slasher Tine, RH

509

130721

8

Bolo Blade, Left

130763

4

Slasher Blade, LH

525

130722

2

Tine Hub, Inner

130776

2

Tine Hub, Inner

526

130723

2

Tine Hub, Outer

130777

2

Tine Hub, Outer

527

130740

1

R Inside Assy. Bolo Tine 130766

1

R Inside Assembly Slasher

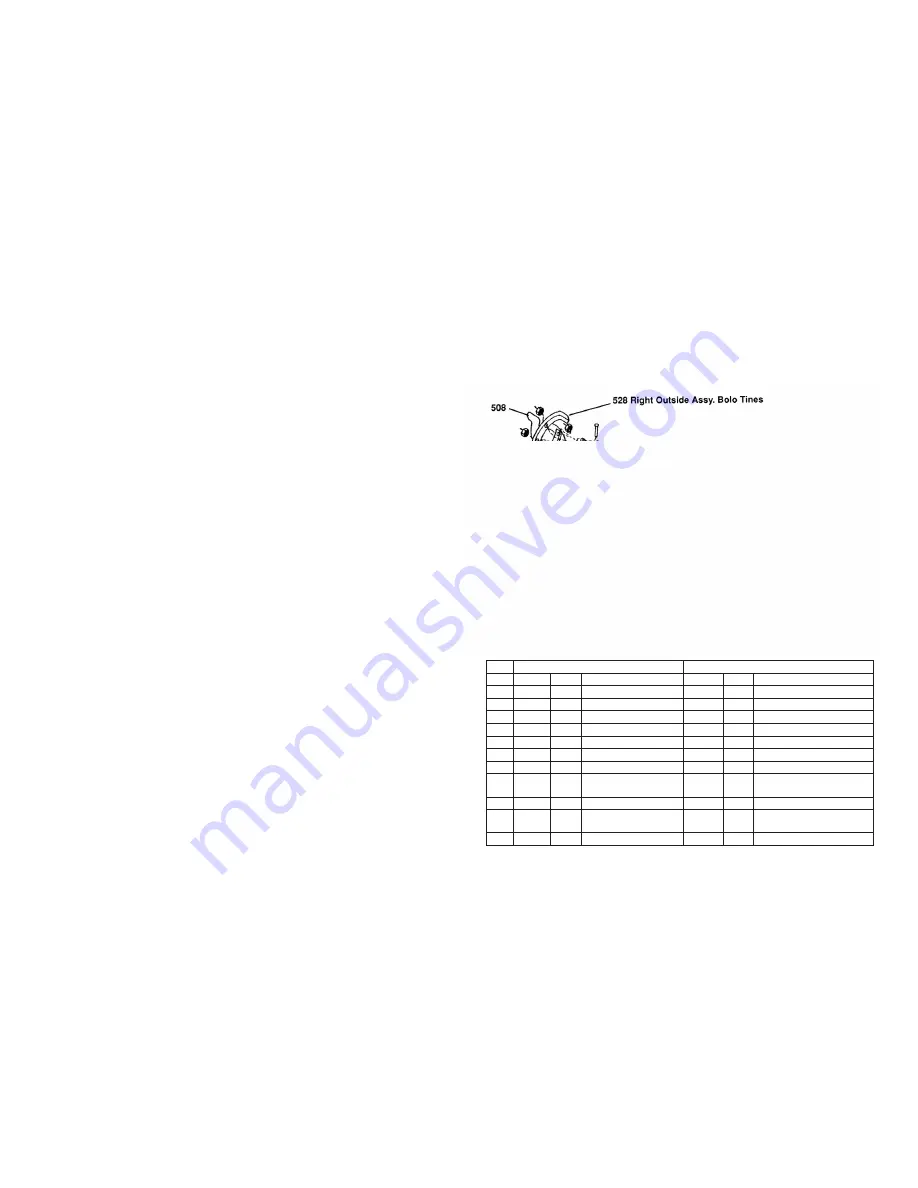

528

130742

1

R Outside Assembl.

Bolo

130768

1

R Outside Assembly Slasher

529

130741

1

L Inside Assembly Bolo

130767

1

L Inside Assembly Slasher

530

130743

1

L Outside Assembly

Bolo

130769

1

L Outside Assembly Slasher

531

130744

1

Bolo Tine Set Complete 130761

1

Slasher Tine Set Complete

8

5. Re-tighten engine mounting bolts.

6. Remove all the slack from clutch cable and hook spring in proper chain link.

7. Check your adjustment by starting the tiller and holding the tines off the ground. If the tines turn without

any hand pressure on the clutch lever, the adjustment is too tight.

Unhook the clutch load spring and hook into next chain link to lengthen clutch cable. If the cable spring on

the clutch handle doesn’t stretch when you hold the clutch handle all the way in, the adjustment is too loose.

Unhook spring end from chain and hook next link to shorten clutch cable.

Adjustments continued

9

Summary of Contents for RMT55H

Page 6: ......