- 8 -

5.1.5. Emergency button

When you press this switch, no operation is available immediately. There is one emergency

button on each control box.

It must be released before lift operation. Then turn on the power switch.

5.1.6. Operation button

“UP” button: Press and hold this button, the carriages will rise.

“DOWN” button: Press and hold this button, the carriages go down to the required height after

system unlocking the hooks automatically.

5.2. Instruction

Working voltage: DC 24V Battery;

Working temperature: 42 ~ 104

o

F;

Working humidity: 50%@104

o

F -90%@68

o

F;

Working altitude: ≤1000m;

Circuit inside control box is forbidden to disassemble or maintenance without permission;

Noise: ≤75dB(A);

6. Debugging

6.1. Power supply

The power supply is 24V Battery;

6.2. Battery charge

Please charge the column when “Please charge battery” occurs onto the screen. The charging

voltage is: AC 220V, 1 phase

6.3. Test process

6.3.1. Single column test

Power on: Connect all 4/6 columns with communication cable, turn the Mode Selection knob

to SINGLE, and power on main column and all slave columns. LCD screen will show work

interface after successful connection.

Rise: Unloaded, press and hold the “UP” button on the master control box, check if the carriage

rises normally. Repeat to try the other columns in same way.

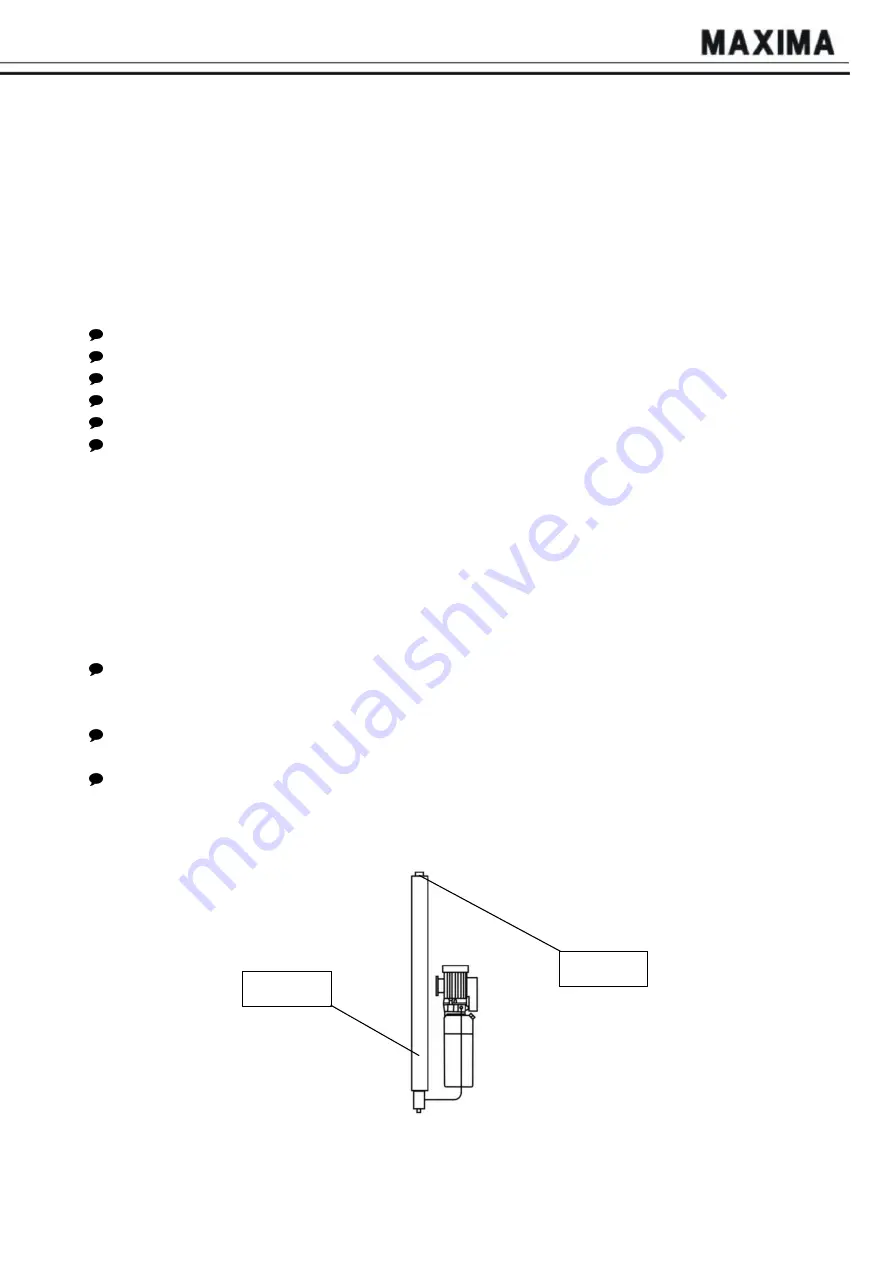

Air release: When the carriage is crawl and wobble in lifting process, please vent the air out of

the cylinder.

Raise the carriages up to about 600mm; loosen the Drain-tap on the top of the cylinder two

turns (see Fig. 8). When there is oil coming out, tighten the Drain-tap.

Cylinder

Drain tap

Fig. 8

Summary of Contents for ML4030B

Page 1: ...MAXIMA HEAVY DUTY COLUMN LIFT ML4030B ML6045BUSER MANUAL ...

Page 14: ... 12 Addendum 1 Hydraulic valve ...

Page 16: ......