5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-112-

9.1 Overview

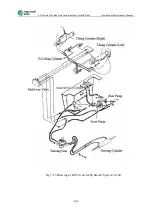

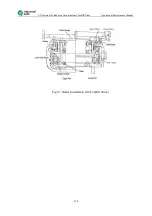

Rolling type is applied to lifting system, and the basic type is a two-stage telescopic mast type. The

inner mast is in a J-shaped section, while the C-shaped section is applied to outer masts for all the

5-8t forklift trucks, other than the outmast in a J-shaped section for 10t forklift truck.

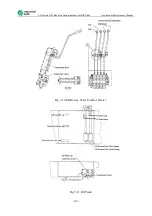

9.2 Outer & Inner Mast

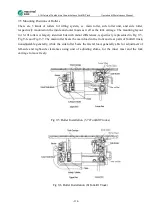

The mast assembly is in a two-stage telescopic type including free hoist, and it is composed of inner

mast and outer mast, to be supported with bracket for mast, with the bracket for mast welded on the

bottom part of the outer mast, extended to the axle housing, and connected together with axle

housing, namely the deadweight of mast is supported by axle housing. There is also the bracket for

tilt cylinder on the outer mast, and the front end of tilt cylinder (namely the end of piston rod) is

connected with this bracket using pin shafts. The mast tilts under the action of tilt cylinder, for a

forward tip of 6° and a backward tip of 12°.

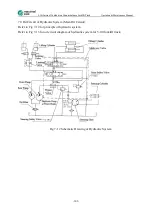

9.3 Fork Carriage

Roller shaft is welded on the fork carriage, and the main roller and its snap ring rolling on the

internal surface along the inner mast are mounted on the roller shaft, while the side rollers rolling on

the inner side along the inner mast are prized onto the inner mast using bolts, and adjusted by

adjusting shim. In order to prevent the sway of fork beam (support plate, or upper cross beam), two

limit rollers are installed, and the limit rollers roll on the outer side face along the inner mast. The

main roller bears the longitudinal load, and the main roller mounted above is exposed (some part),

when the Fork rises to the maximum lifting height, while the limit rollers above and the side rollers

below withstand the traverse load. Enough rigidity and strength have been taken into consideration

about the design of mast assembly and fork carriage, while operating stability has been also

considered at the same time.

Besides, the upper and lower cross beams of fork carriage are made of

high-strength steel, and the fork carriage is made into an integrated

structure, to ensure its durability. It complies with ISO standard

(international standard).

Two forks are loaded on the fork carriage. The forks are made of alloy

steel, and are heat treated.

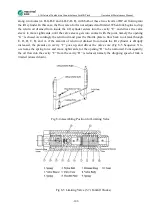

9.4 Adjustment of Lifting System

9.4.1 Gasket Adjustment for Lift Cylinder Head

When lift cylinder, inner mast or outer mast is disassembled and

replaced, the stroke of lift cylinder shall be readjusted.

The adjusting method is described as follows:

(1)Load the head of piston rod not added with adjusting shim into the

upper cross beam of inner mast.

(2)Slowly raise the mast to the maximum stroke of cylinder, and examine whether or not the two

cylinders are synchronous.

(3)Add the adjusting shim between the head of piston rod for the cylinder that has firstly stopped

movement and the upper cross beam of inner mast. Fig 9-1

Thickness of Adjusting Shim: 0.2

㎜

-0.5

㎜

(4)Adjust the tensioning degree of the chain.

Summary of Contents for FD100T

Page 12: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 12 ...

Page 15: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 15 ...

Page 63: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 63 ...

Page 65: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 65 ...