5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-73-

(2)Brake Working Status

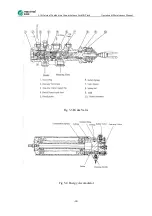

A. When brake pedal is just pushed down, the pedal force acts on the control valve stem 1

through lever amplification, and compresses part 3, to move forward together with part 5.

Through action of the feedback disc 10 and the master cylinder push rod 13, certain pressure

is generated inside the brake master cylinder and transmitted to the brake wheel cylinder

inside the brake wheel, and at the same time, the control air valve 4 moves forward with part

5 under the action of small tapered spring 6, to get contact with the port of vacuum valve on

the control valve body 7, and close it, for the two front and rear cavities of power-assisted air

chamber to be separated from each other (namely the rear cavity of power-assisted air

chamber is disconnected with the vacuum source.).

B. Along with the further forward movement of the control valve push rod 1, the control valve

piston 5 leaves the part 4, and the external atmosphere is filled into the rear cavity of

power-assisted air chamber through the air filter gasket as well as the control valve cavity and

the passage B, thus most of the forward acting force caused by air pressure difference in the

two cavities of power-assisted air chamber is effected on the feedback disc, and transmitted to

the brake master cylinder, to play the power assisting function, through the control valve body

7, except a small part of the action force used for balancing the action force of the large

tapered spring 3.

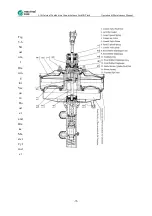

3. Brake Process Termination, and Recovery to Non-Working Status

A. In the process when brake pedal is pushed (namely the forward movement of the control

valve push rod), air continuously enters into the front and rear cavities of power-assisted air

chamber through the opened air valve port, and the control valve body keeps moving forward.

When brake pedal stops being pushed and stays at certain position, the control valve body

also moves forward and stops at the position where the air valve port is closed. At this point,

the vacuum valve port and the air valve port are both closed, the booster is under the balanced

status, namely a balanced status is maintained among the three including the air pressure

difference between the front and rear cavities of power-assisted air chamber, the pressure of

oil pressure for brake master cylinder, and the thrust of the control valve push rod, and the

wheel brake is under the braked status.

B. When brake pedal is released, the control valve push rod 1 and the control valve piston 5

are immediately pushed rearwards under the effect of return spring 14 and large tapered

spring 3, for the control air valve 4 to be disengaged from the vacuum pump port, and then a

braking process is completed, and it recovers to the original non-working status.

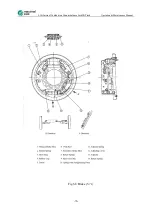

5.3.2 Method for Installation of Vacuum Booster and Brake Master Cylinder Assembly

(1)Connect the 4-M8 bolts for the booster with the mounting bracket and mount it on the

frame of forklift truck. Connect the adjusting fork on the end part of booster with the

connecting rod of brake pedal. Then tighten the 4-M8 bolts, at a tightening torque of

12N.m-18N.m.

(2)Connect the vacuum hose onto the joint of vacuum pipe for the booster, and keep it sealed.

(3)Connect the brake oil pipe with the 2-M10x1 thread for the oil outlet of brake master

cylinder, at a tightening torque of 12 N·m-18 N·m.

(4)Open the turning lid of liquid storage room, and inject the brake fluid (not to be blended

with dust or impurity). Exhaust the air inside the entire brake system.

Summary of Contents for FD100T

Page 12: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 12 ...

Page 15: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 15 ...

Page 63: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 63 ...

Page 65: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 65 ...