5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-74-

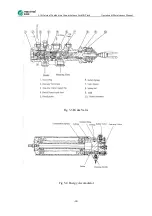

(5) The tightening torque is 12 N·m-16 N·m for the connecting nuts between the brake master

cylinder and the vacuum booster, when brake master cylinder or vacuum booster is separately

replaced.

(6) Please never randomly adjust the push rod head on the fitting face of vacuum booster and

brake master cylinder.

5.3.3 User Notices

(1) Brake fluid specified in this operation manual must be used for this product.

(2) Air in the pipeline must be fully exhausted, after this assembly is added with brake fluid.

(3) Observe that the liquid level of liquid storage tank shall be at the middle position, after air

exhaust is completed.

(4) Any of the failures and effects listed in Table 5-3 shall be repaired by qualified

professionals.

5.3.4 Failure and Cause Analysis – Refer to Table 5-3.

Table 5-3

Failure and Effect

Cause Analysis

No Oil Pressure for Two Cavities or Any Cavity of Master

Cylinder Created, Represented in a Sudden Enlargement in

Pedal Stroke

1. Rubber Ring of Master Cylinder

Worn out

2. Oil Outlet Pipeline Damaged

Output Oil Pressure not Large, while Pedal Force Turned to be

Heavy

1. Vacuum of Booster Leaked

2. Engine Vacuum Pipeline Leaked

Frequent Oil Starvation for Oil Reservoir

1. Joint Area of Cylinder Leaked

2. 1

st

Piston Rubber Ring of Master

Cylinder Worn out

Brake Pedal Low and Soft

1. Air Present in Oil Circuit System

2. Clearance between Booster Push Rod

and Master Cylinder Piston too Large

5.4 Wheel Brake

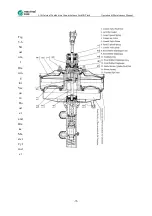

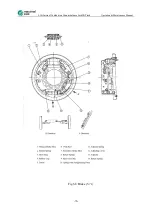

The 5-7t wheel brake is an internal expanding and shoe brake, one for left

and right symmetrically, respectively installed inside the two driving

wheels. The brake is composed of one pair of brake shoe assemblies (one

as primary and secondary brake shoes, respectively), brake wheel cylinder

(one for 5-7t), one clearance adjuster, 3-4 return springs, and the bottom

plate of brake. The outside of the brake shoe is riveted with a friction plate,

and the clearance adjuster is used to adjust the clearance between the

friction plate of brake shoe and the inner wall of brake drum.

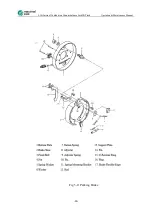

The 8-10t brake is a clamping brake, with brake calipers symmetrically

mounted on the outer edge of the brake disc. Piston pushes the brake

block under hydraulic action, to bear down on the brake disc during brake,

for brake moment to be generated. After the brake pressure is eliminated,

the piston resets to the original position under the effect of return spring tension.

Summary of Contents for FD100T

Page 12: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 12 ...

Page 15: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 15 ...

Page 63: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 63 ...

Page 65: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 65 ...