5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-86-

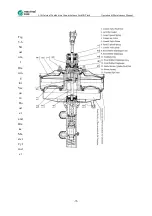

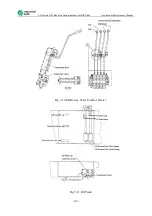

When engine is flamed out, the steering wheel is controlled depending on manual force, to drive

the rotor through valve core, poking pin, and universal driving shaft and to press the oil from

one cavity of the steering cylinder into the other cavity, through, to drive the steering wheel, so

as to achieve manual steering (d in Fig 6-4). Oil is supplied from oil tank through one-way valve

for oil supply.

BZZ1-model steering unit used for this forklift truck is an open-core nonreactive type, namely

the external force acted on the steering wheel cannot be transmitted to steering wheel. The

driver has no road sense.

6.1.3 Application Requirements

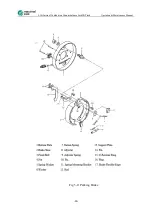

(1) Installation

When steering unit is installed, it shall be ensured that it shall be concentric with the connecting

shaft assembly on the lower end of universal joint, and axial clearance shall exist, to avoid valve

core from being jammed up, and it is required to examine whether or not steering wheel can

reset flexibly.

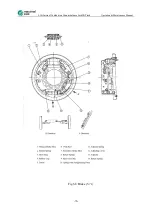

For pipeline installation, the “Inlet” marked at the joint of steering unit shall be connected with

the oil pipe from oil pump, while the marked “Return” is to be connected with oil tank, and the

marked “Left” and “Right” shall be respectively connected with the left cavity and the right

cavity of steering cylinder.

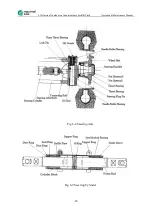

The allowable flow rate for oil suction pipe is 1-1.5m/s, while the allowable flow rate for

pressure oil pipe and return oil pipe is 4-5m/s, and the test pressure for high-pressure hose shall

not be lower by 1.5 times than the maximum operating pressure.

The section of oil tank position shall be higher than the mounting position of steering unit, and

oil suction pipe shall be inserted into the oil level, thus to be able for oil supply during manual

steering, and at the same time to be able to avoid blending of air into oil.

To facilitate safety and repair, it is recommended to set a pressure gauge adapter in the place of

oil inlet for steering unit, so that the pressure gauge can be installed.

(2)Range of Oil Temperature: -20

℃

~

+80

℃

Normal Oil Temperature: +30

℃

~

+60

℃

(3)Selection of Oil Used: N46 or N32 Hydraulic Oil

(4)Filtration: The filtration precision for oil liquid into steering unit is 30μm, and it shall be

ensured that the return oil of steering unit has a 0.2-0.3MPa back pressure, to prevent backflow

of oil into oil tank during manual steering.

(5)All the pipelines in the system shall be cleaned up, and the oil tank shall be closed, to

minimize oil pollution.

(6)Test Run: Test Run: Prior to operation oil tank shall be cleaned, and oil shall be injected to

the maximum oil level. Loosen the threaded joint for the cylinder, for the oil pump to operate at

low speed for air bleed, until the outgoing oil contains no foam anymore.

Remove the connection between piston rod and steering wheel, and turn the steering wheel, for

piston to reach the leftmost or the rightmost position (staying to be avoided at the two extreme

positions, and then further add oil into the oil tank up to the maximum oil level.

Tighten all the threaded connection places (tightening under pressure to be avoided), connect

the piston rod, and examine whether or not the work of steering system is normal under various

working conditions. It is required to search for the causes carefully when heavy steering or

malfunction is found. It is not allowed to turn the steering wheel forcibly, and moreover to take

it apart in a hurry, to prevent the damage of parts for the steering unit.

Summary of Contents for FD100T

Page 12: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 12 ...

Page 15: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 15 ...

Page 63: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 63 ...

Page 65: ...5 10t Internal Combustion Counterbalance Forklift Truck Operation Maintenance Manual 65 ...