VP30/VP500

MAINTENANCE INFORMATION

Blowing safety Valves

Possible reasons for safety valves blowing are given below. In addition to these reasons, it may be

possible that the safety valves themselves can be faulty. Safety valve adjustments may change

due to vibration, or the valve may be worn.

In general, the normal operating pressures of the three stages of the compressor will be as follows:

1st stage: up to 21 Bar

2nd stage: up to 97 Bar

3rd stage: up to 350 Bar

If a safety valve is blowing below the pressures given above for each stage, then it is likely that the

valve requires adjustment or replacement.

Note: It is extremely dangerous to adjust safety

valves pressures without the correct equipment. Replacement is recommended.

Crankcase breather safety valve blowing

1st stage cylinder head gasket damaged. Check and replace.

1st stage suction valve faulty. Check and clean/replace.

1st Stage safety valve blowing

2nd stage cylinder head gasket damaged. Check and replace.

2nd stage suction valve faulty. Check and clean/replace.

2nd Stage safety valve blowing

3rd stage concentric valve and/or seals worn or damaged. Check and clean/replace.

3rd Stage safety valve blowing

Outlet Check Valve or outlet pipes blocked. Check and Clean/Replace

Leakage from HP receivers

If the pressure in the HP receivers or pipework reduces, even when no gas is being consumed, it is

possible that the compressor outlet check valve is faulty and that gas is leaking back through it and

to the unloader vent, when the compressor is not running. Check and replace check valve.

Low oil pressure

Low oil level - Check and refill oil pump suction strainer fitted to drain plug 2/15 is clogged. Drain

the compressor oil and clean the strainer. Use compressed air to blow away any dirt, from the

inside of the strainer.

Knocking

Hard metallic knocking noises normally indicate worn crankpin journals or big end bearings. If the

crankpin journals are excessively worn, the crankshaft 3/1 must be replaced. If the wear is minor,

the connecting rods 4/1 (3 pcs) may be replaced.

July 21

13 of 42

Summary of Contents for VP30

Page 15: ...VP30 VP500 MAINTENANCE INFORMATION Fig 2 Crankcase July 21 15 of 42 ...

Page 17: ...VP30 VP500 MAINTENANCE INFORMATION Fig 3 Crankcase July 21 17 of 42 ...

Page 19: ...VP30 VP500 MAINTENANCE INFORMATION Fig 4 Piston and connecting rod July 21 19 of 42 ...

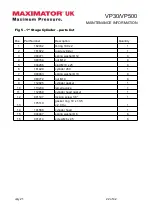

Page 21: ...VP30 VP500 MAINTENANCE INFORMATION Fig 5 1st Stage Cylinder July 21 21 of 42 ...

Page 23: ...VP30 VP500 MAINTENANCE INFORMATION Fig 6 2nd Stage Cylinder July 21 23 of 42 ...

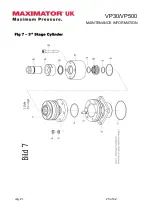

Page 25: ...VP30 VP500 MAINTENANCE INFORMATION Fig 7 3rd Stage Cylinder July 21 25 of 42 ...

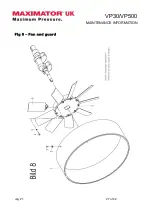

Page 27: ...VP30 VP500 MAINTENANCE INFORMATION Fig 8 Fan and guard July 21 27 of 42 ...

Page 29: ...VP30 VP500 MAINTENANCE INFORMATION Fig 9 Coolers July 21 29 of 42 ...

Page 31: ...VP30 VP500 MAINTENANCE INFORMATION Fig 10 Unloader Manifold July 21 31 of 42 ...

Page 34: ...VP30 VP500 MAINTENANCE INFORMATION Fig 11 Unloaders July 21 34 of 42 ...

Page 36: ...VP30 VP500 MAINTENANCE INFORMATION Fig 12 Oil Lubrication July 21 36 of 42 ...

Page 38: ...VP30 VP500 MAINTENANCE INFORMATION Fig 13 Crankcase Breather July 21 38 of 42 ...

Page 40: ...VP30 VP500 MAINTENANCE INFORMATION Fig 14 Motor July 21 40 of 42 ...