13

12

model no.

058-9342-6

| contact us 1-888-670-6682

• Do not use the tool if it is not in proper working order.

• Do not use oxygen, CO2 (carbon dioxide) or any other combustible, or

bottled gas to power this tool.

• Do not use this tool in the presence of any flammable liquids or gases.

• Keep hands and other parts of the body away from the firing head during

use.

• Do not point the tool towards the operator or other people.

• Never attempt to clear a jammed fastener while the air hose is connected.

• Do not drive a fastener on top of an existing fastener. Failure to comply

could lead to serious injury or death.

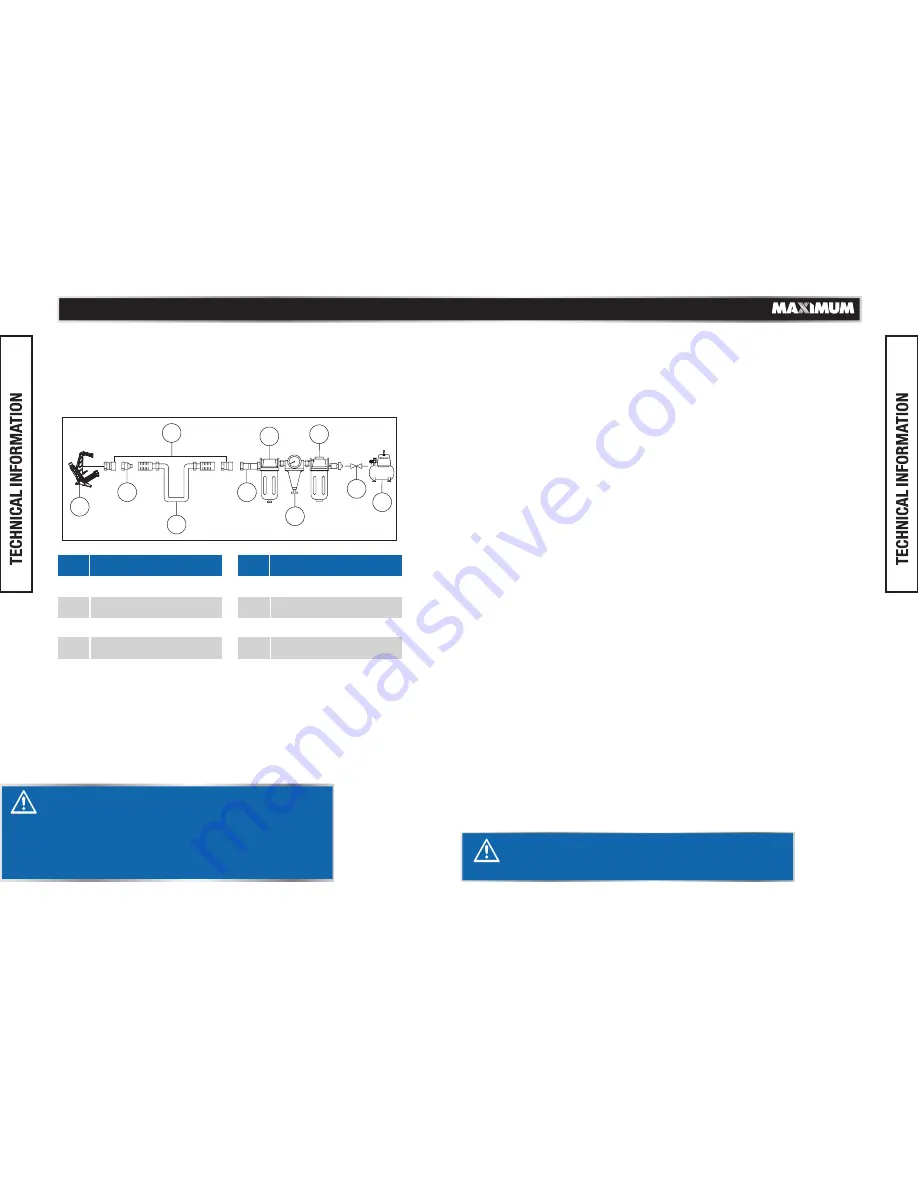

• It is recommended that a filter-regulator-lubricator is used and located

as close to the tool as possible.

• If a filter-regulator-lubricator is not installed, place up to 6 drops of

compressor oil into the NPT inlet plug before each use.

• If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty

filter will reduce the air pressure to the tool, which will cause reduction

in power, efficiency, and general performance.

• For optimal performance, install a quick connector to the tool and a

quick coupler on the hose, if applicable.

• Verify that all of the connections in the air supply system are sealed in

order to prevent air from leaking.

AIR TOOLS

Read this Instruction Manual carefully before using the tool.

• Read and follow all the safety instructions at the beginning of this

manual. Inspect the Air-powered tool prior to each use in order to:

– Ensure that the proper power source is being used.

– Verify that the tool is in proper working order.

– Verify that the air pressure level(s) are properly set on the air

compressor.

WARNING!

Potential hazard that could result in serious injury or

death.

• Keep hands and other parts of the body away from

the tool’s discharge and working areas when

connecting the air supply. Failure to comply could

lead to serious injury or death.

WARNING!

Potential hazard that could result in serious injury or

loss of life.

Air system

• Always use clean, dry, regulated, compressed air at 5.5 to 7.5 bar

(80 to 110 PSI).

• Do not exceed the maximum or minimum pressures. Operating the

tool at the wrong pressure (too low or too high) will cause excessive

noise or rapid wear of tool.

MAXIMUM

®

Air-powered 2-in-1

Description

No.

No.

6

7

8

(0–8.5 bar)

Filter

Cut-off valve

Quick connector

Quick coupler

Air hose

Lubricator

Description

1

2

3

4

5

9

Flooring Nailer

Regulator 0–123 PSI

Air compressor

2

5

7

1

3

3

6

8

9

4

TM