Installation manual

Liftgate GPC 22 X-1, Series 11

Document no.: S 20 912 436

42

Version 2021

LED diagnostics in series 11

Explanations for LED diagnostics of the control unit with service switch on series 11

main electrical system, main control unit with service-switch)

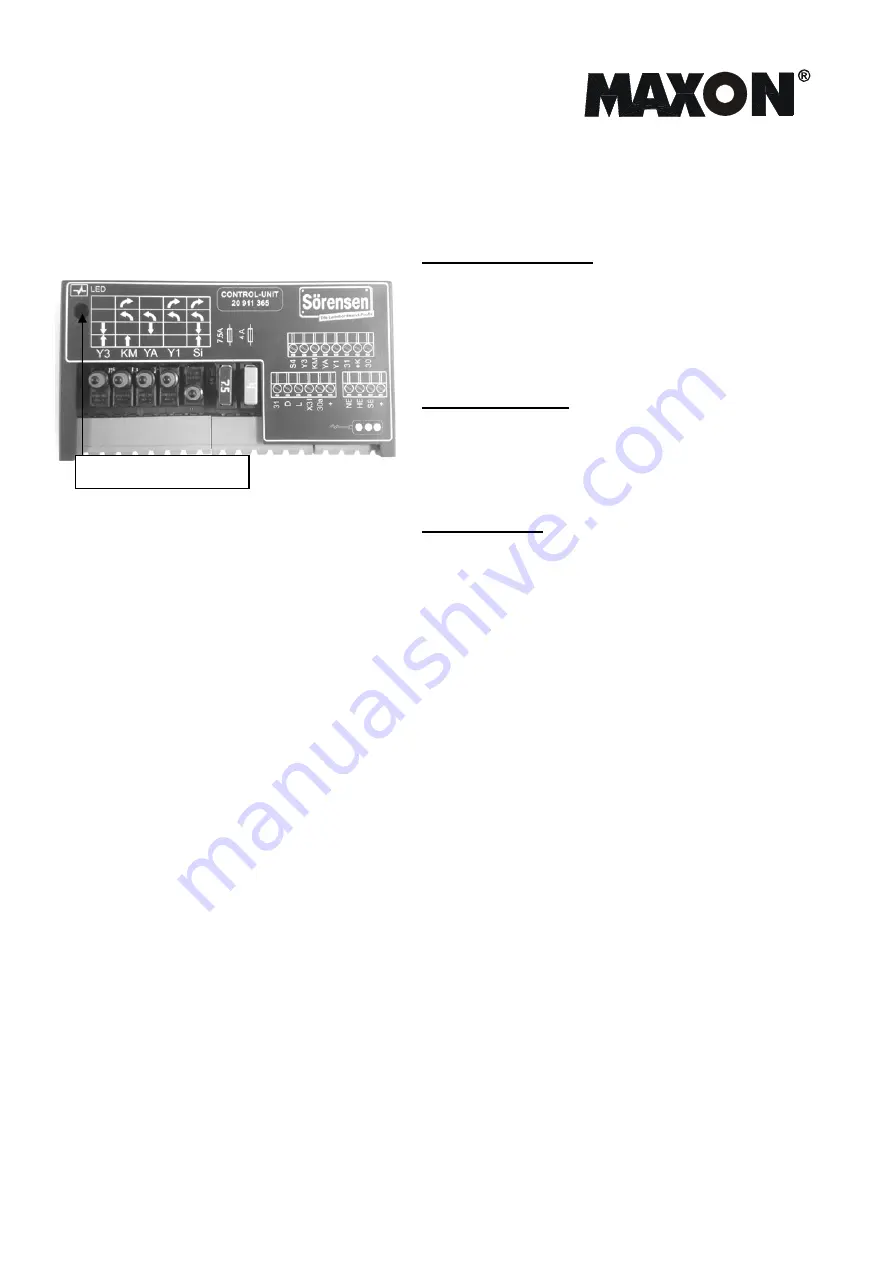

Series 11 control-unit

Checking the inclination sensor inside the platform

platform closed and liftgate switched on:

LED on

electrical supply OK

platform position 0º to about 60º

LED off

inclination sensor S1 triggered and OK

corner lights are activated

platform position 0º to -10º (platform tilted down)

LED on

inclination sensor S2 activated and OK

The switch occurs in horizontal position. This allows adjusting the automatic lifting inclination

Checking the pressure switch S4:

Start lowering with both foot control buttons.

LED blinks

As soon as the platform reaches the ground, and the pressure switch is triggered, the blinking

stops and the LED stays on. LED is on and the platform tilts down.

This shows that the pressure switch was triggered. If not, the pressure switch is defective.

LED stays on when:

cabin switch is on or

platform position 60º to 90º

platform position 0º to -10º

Explanation: platform CLOSED (vertical) 90º

platform OPEN (horizontal) 0º

platform tilted down -10º

LED tilting when:

hand buttons are triggered

or

foot control is used

or

remote is used

LED off when:

cabin or key switch is off

or

platform position 0º to 60º

LED diagnostics

Summary of Contents for GPC 22 X1

Page 2: ......