Operation of the GPC X1-LD and GPC X1-LDF liftgates

22

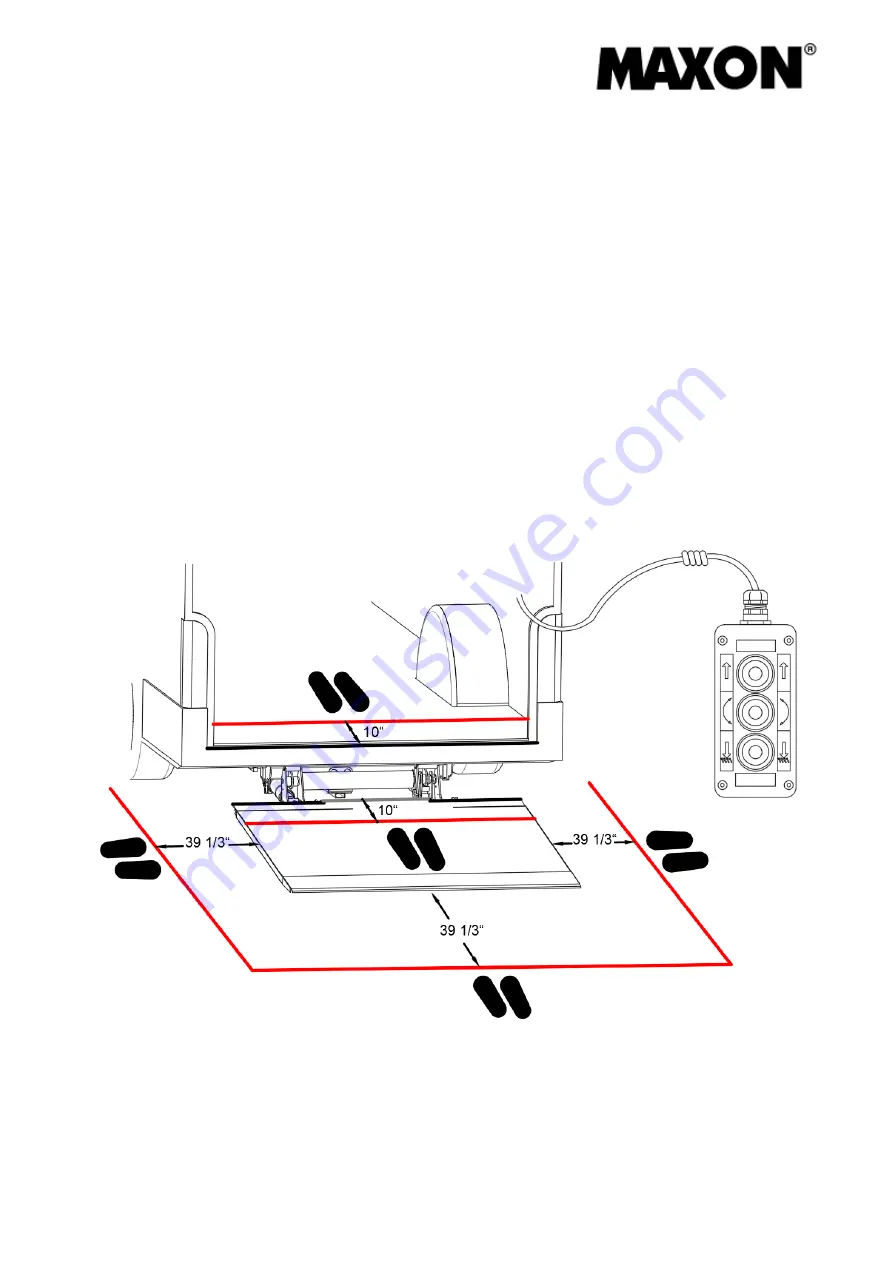

3.4.1 Operating positions and safety distances when using the optional

handheld control with spiral cable

IMPORTANT

When using a handheld control with a spiral cable, the operator may initiate liftgate

functions only while standing in the positions shown in the illustration.

Operating position on the platform or vehicle floor

The operator must stand a minimum of 10 inches from the front edge of the platform or

rear edge of the vehicle floor.

Operating position from the ground

When operating the platform from the ground, the operator must stand at least 39 1/3

inches from all edges of the platform and from the crushing edge between the platform

and vehicle.

Summary of Contents for GPC X1-LD

Page 44: ...Electrical circuit diagram 40 Electrical circuit diagram...

Page 45: ...Hydraulic circuit diagram 41 Hydraulic circuit diagram...

Page 48: ...Notes 44 Notes...

Page 49: ...45...

Page 50: ...46...