Maintenance

28

Maintenance

4.1 Daily visual inspections

Check functioning and completeness of the operating and safety devices.

Check that all warning and instruction labels are legible. Check for damage and

completeness of pins and check that pins are securely tightened. Check cylinders for

damage to/tightness of hoses, screw connections, and valves. Check warning lights for

damage and functioning.

Check functioning of battery master switch (optional equipment).

4.2 Annual inspection

After commissioning, the liftgate must be inspected at least once a year by trained

personnel. The results of this inspection must be entered in the inspection record book.

4.3 Care, maintenance, testing, and repair

Before starting maintenance, secure the liftgate against unexpected movement. Check

that all screw connections are tight.

Check that cables and hoses are able to move freely. Correct shearing and chafing

points on cables and hoses. Immediately replace damaged hydraulic hoses with new

hoses of the same quality and note the replacement in the inspection record book.

During cleaning, make sure that no moisture penetrates the power pack, control panel, or

handheld control. Do not clean the bearing areas with high-pressure or steam jets

because this may allow dirt and moisture to penetrate the bearing.

Check the hydraulic unit for leaks. With the liftgate platform completely lowered, check

the oil level in the unit's reservoir (dipstick on the oil filler neck cover). If necessary, top

up with hydraulic fluid of class HLPD 22 (temperature range 5°F to +122°F).

The maximum oil level has been reached when the dipstick dips 3/8“ into the oil.

Carry out an annual oil change and clean the suction filter. Carry out the oil change

before any period of frost, in order to prevent the hydraulic unit from freezing.

Summary of Contents for GPC X1-LD

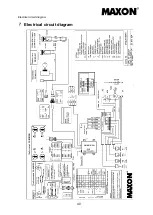

Page 44: ...Electrical circuit diagram 40 Electrical circuit diagram...

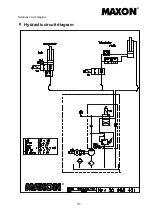

Page 45: ...Hydraulic circuit diagram 41 Hydraulic circuit diagram...

Page 48: ...Notes 44 Notes...

Page 49: ...45...

Page 50: ...46...