7

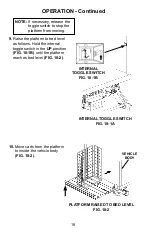

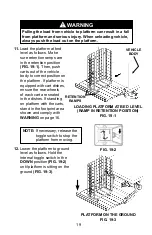

Check the platform and fl ipover for cracks, holes, and bends on the

load-carrying surface and side plates. Also, make sure torsion bars,

coil springs, and fasteners are in place and undamaged.

Make sure platform and fl ipover load-carrying surfaces are clean (no

oil, debris, or corrosion).

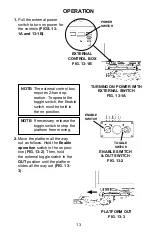

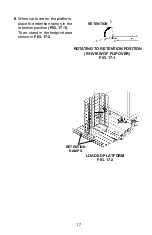

Use the operation instructions in this manual to operate the Liftgate

through one cycle without a load on the platform. Raise the platform

to vehicle bed height. Next, lower the platform to ground level.

When the Liftgate is moving, listen for unusual noises and look for a

“jerking” motion or uneven movement on either side of the platform.

If service or repairs are not required (or if completed), stow the Lift-

gate.

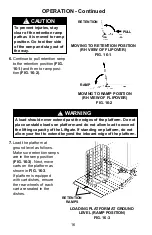

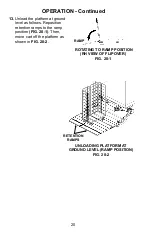

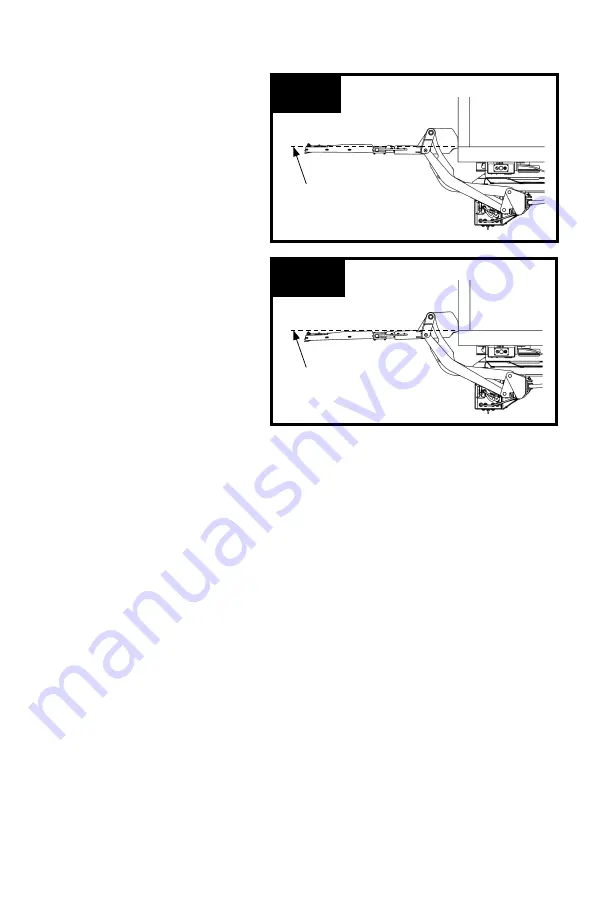

With the platform un-

folded and raised to bed

level, check if the platform

is level

(YES illustra-

tion)

. If the platform looks

like the

YES illustration

,

you can operate Liftgate.

If the platform is below

level line and platform

looks like the

NO illustra-

tion

, do not operate the

Liftgate. (See

NOTE

at

beginning of the

DAILY

OPERATION CHECKS

.)

YES

NO

LEVEL LINE

LEVEL LINE

Summary of Contents for GPSLR

Page 1: ...M 08 13 DECEMBER 2008 OPERATION MANUAL MAXON Lift Corp 2008...

Page 2: ......

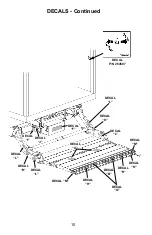

Page 9: ...9 DECAL SHEET FIG 9 1...

Page 11: ...11 DECAL SHEET 267432 01 FIG 11 1...

Page 12: ...12 FORKLIFT ADVISORY WARNING Keep forklift OFF of platform FIG 12 1...

Page 24: ......