Low temperature burners - INDITHERM

®

w w w . m a x o n c o r p . c o m

combustion systems for industry

MAXON reserves the right to alter specifications and data without prior notice.

© 2008 Copyright Maxon Corporation. All rights reserved.

1 - 2.3 -

21

E - m - 7/08

Start-up instructions for INDITHERM

®

burners

Instructions provided by the company or individual responsible for the manufacture and/or overall installa-

tion of a complete system incorporating MAXON burners take precedence over the installation and operat-

ing instructions provided by MAXON. If any of the instructions provided by MAXON are in conflict with local

codes or regulations, please contact MAXON before initial start-up of equipment.

Initial adjustment and light-off should be undertaken only by a trained commissioning engineer.

First firing or restart after shut-down

During first start-up of the burner, allow extended period at low firing range to minimize potential damage from accumulated

and retained moisture in refractory burner block.

During cold starts, the temperature rise shall be limited – allow the burner to fire on low fire for some time to allow the parts to

heat up slowly for maximum life.

Safety interlocks

Guarantee that all the required safety locks as described in the applicable local codes or regulations, or supplementary safety

blocks requested for safe operation of the overall installation, are working properly and resulting in a positive safety-lock of the

burner. Do not bypass any of these safety interlocks, this will result in unsafe operation.

Checks during and after start up

During and after start-up, check the integrity of the system. Check all bolted connections after first firing (first time on tempera-

ture) and retighten if necessary.

Purge

For safety reasons, it is required to purge the installation sufficiently long to ensure that all possible combustibles are evacu-

ated before ignition. Refer to the applicable local codes and your specific application requirements to determine the purge time.

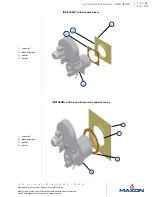

Pilot ignition

Adjust pilot air flow and pilot gas regulator to correct set point before pilot ignition attempt.Turn adjustable orifice screw out

(counter-clockwise) several turns from its fully seated position. Refine during lighting of the pilot to a yellow/blue flame and/or

strongest stable flame signal.

Main burner ignition

Adjust the main gas regulator at the correct set point before igniting the main burner. Ensure that the gas/air ratio valve is in the

start position when lighting the main burner.

After ignition of main burner, allow some time on minimum capacity to allow the burner parts to heat up slowly.

Burner adjustment

Once the main flame is ignited, adjust gas pressure to the burner to have the required combustion quality. Slowly increase

capacity while observing the flame and measuring flue gas quality. Do not increase capacity too fast to avoid damage to burner

parts or furnace due to excessive temperature gradient.

Read the combustion system manual carefully before initiating the start-up and adjustment

procedure.Verify that all of the equipment associated with and necessary to the safe

operation of the burner system has been installed correctly, that all pre- commissioning

checks have been carried out successfully and that all safety related aspects of the

installation are properly addressed.