Low temperature burners - INDITHERM

®

w w w . m a x o n c o r p . c o m

combustion systems for industry

MAXON reserves the right to alter specifications and data without prior notice.

© 2008 Copyright Maxon Corporation. All rights reserved.

1 - 2.3 -

9

E - m - 7/08

Burner designation

Fuels

INDITHERM

®

burners are designed to operate on natural gas. For propane and butane operation a standard INDITHERM

®

burner can not be used. Contact MAXON when the use of gases other than natural gas is inevitable.

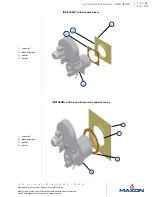

Burner discharge sleeve

The burner discharge sleeve is available in different materials and geometries:

Standard version

with circular stainless steel discharge sleeve and square burner mounting plate.

High temperature version

with refractory block for installation in applications where high temperatures can be expected.

In following cases the use of high temperature version discharge sleeve is required:

Dimension A is larger than 50mm

Insufficient low temperature process air is available to cool the discharge sleeve

No process air is available ( typical in indirect fired applications)

Process air is entered downstream of the burner, being unable to flow over the burner discharge sleeve

Burner type

Burner size Burner gas connection

Discharge sleeve

Ignition

Flame supervision

INDITHERM

®

300

ISO

HTS

DI

UVC

Burner size

100

300

550

700

850

1100

1500

1800

Burner gas connection

ISO: ISO threated

NPT: NPT threaded

Discharge sleeve

HTS: High temperature

STD: standard version, stainless steel

Ignition

DI: Direct Ignition (plugged pilot port)

PL: Pilot burner

Flame supervision

UVC: prepared for UV-scanner mounting

FRC: prepared for flame rod mounting

Process air

A