10

2.6

INSTALLATION OF CONTROLS

The windlass can be operated using:

•

Deck mounted footswitches

•

Hand held pendant controller (single or dual

speed)

•

Helm switch

•

Chain counter

These control accessories are available from

Maxwell customised to suit your windlass.

It is the choice of the designer/builder to use one,

two or all three of these controls. They are wired in

parallel to the directional valve (for hydraulic

windlasses) or to the starter unit (for electric

windlasses). The controls can work on 12 or 24V

power supply.

If footswitches are used, then an isolator switch for

them must be installed in the wheelhouse, to prevent

operating the windlass by someone accidentally

stepping on the footswitch.

Hand held pendant controller is often the most

convenient way of operating the windlass. Maxwell

offers several variations of pendants, including single

speed, dual speed, single pendant for running a pair

of windlasses, pendants with auxiliary buttons which

can be used for starting chain wash system,

hydraulic pump etc. They are supplied with a plug on

the other end of cable and a matching waterproof

socket, which should be installed on a convenient

location on the deck.

All units are supplied with detailed wiring instructions

to assist installation.

Refer to wiring schematics in Appendix C for control

circuits. All control wiring should be done using no

smaller than 1.5mm² wire (AWG 16).

A manually re-settable, ignition proof 3A breaker or

fuse should be installed on the power supply line for

controls, within 1m (40”) from the main

breaker/isolator. These requirements are mandatory

to meet USCG, ABYC and NMMA rules.

After connecting the power lines, spray all ports and

fittings with anti-corrosive waterproof coating “CRC

3013 Soft Seal” or equivalent.

Picture 2.9

Pendant controller for operating two windlasses

2.7

NOTE TO BOAT BUILDER

Experience has shown that, on long ocean

deliveries, sulphur from the ship's exhaust can settle

on polished surfaces, which can affect the quality of

the finish.

Please ensure that, upon completion of installation,

the windlass is treated with suitable corrosion

protective coating (“CRC 3097 Long Life”) and

wrapped in plastic film. This ensures that your

customer receives the windlass from you in the same

top quality condition as you received it from Maxwell.

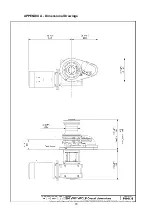

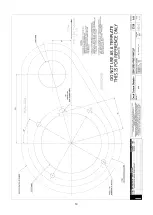

Summary of Contents for VWC 2500

Page 1: ...2500 VWC VWCLP MANUAL ...

Page 20: ...18 APPENDIX A Dimensional Drawings ...

Page 21: ...19 ...

Page 22: ...20 APPENDIX B Topworks Spare Parts ...

Page 23: ...21 ...

Page 25: ...23 APPENDIX C Electrical Wiring Schematics ...

Page 26: ...24 ...

Page 28: ......

Page 29: ...NOTES ...