25

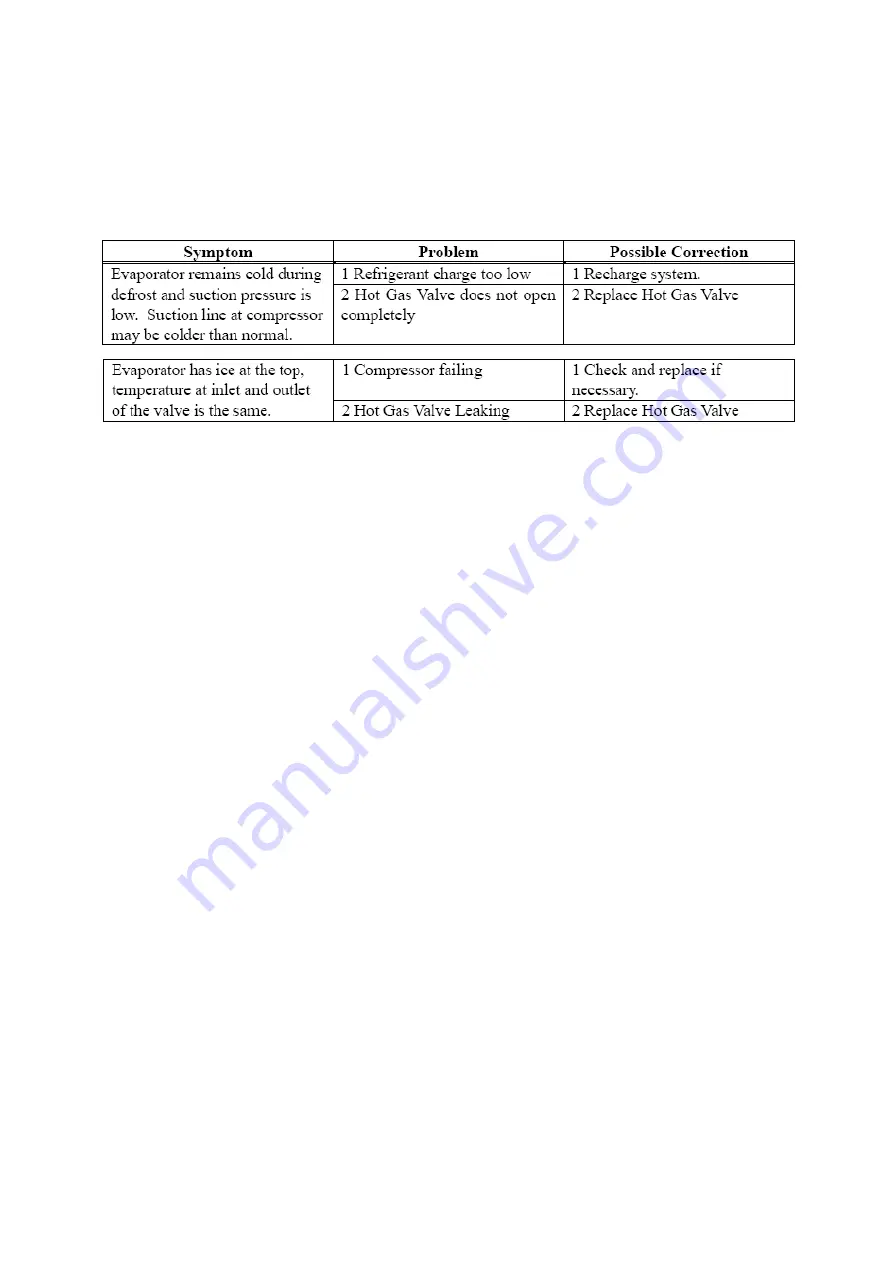

functioning properly. If the hot gas valve leaks during the freeze cycle, ice will not form on the top

of the evaporator and suction pressure will be higher than normal. To check if the hot gas valve is

leaking, let the machine run in the freeze cycle for approximately 5 minutes. Now feel the

temperature between the inlet and outlet of the valve. A definite temperature difference should be

felt. If the lines are the same temperature and the suction pressure is higher than normal; the valve is

leaking and should be replaced.

Evaporator

As water is circulated over the front of the evaporator, liquid refrigerant is circulated through the

tubing attached to the back of the evaporator. As the liquid refrigerant in the tubing vaporizes, it

absorbs heat from the water causing the water to freeze. The evaporator should be completely

flooded throughout most of the freeze cycle. A flooded evaporator will build ice evenly across the

evaporator. A starved evaporator will have thick ice at the bottom and thin ice at the top. Most

problems with ice formation or harvesting are not related to a defective evaporator.

If the evaporator is flooded but not building ice evenly, it is possible the evaporator has coil

separation. Evaporator coil separation is the separation of the refrigerant tubing from the back of the

evaporator plate. This is very rare but occasionally occurs. The symptoms of coil separation are low

suction pressure, ice not releasing from the evaporator during harvest and hollow cubes or uneven

ice bridge on some areas of the evaporator.

If coil separation is suspected, let the machine run in freeze until the timer has energized. Check the

evaporator for areas where cubes are less developed than cubes in other areas. If the cubes are all

the same size, coil separation is not the problem. If there are areas other than the top row with less

developed cubes, check the refrigerant lines at the inlet(s) and outlet(s) of the evaporator, if both

lines are frosted the coil is separated. To confirm coil separation, remove and check the back of the

evaporator. If the coil is separated, the evaporator must be replaced. If the outlet(s) of the

evaporator is not frosted, the problem is not with coil separation (refer to Troubleshooting).

Note:

Permanent discoloration of the evaporator plating is normal and will cause no problems with

harvesting the ice or sanitary conditions. Before condemning the evaporator for plating problems,

be certain it is not just discoloration. Good evaporators will not be covered under warranty. If the

spillway (plastic evaporator top) becomes damaged, it can be replaced. It is not necessary to replace

the entire evaporator.

As liquid refrigerant leaves the evaporator, it changes to a lowpressure gas before returning to the

compressor. Liquid refrigerant must not return to the compressor or damage will result. Frost on the

suction line at the inlet of the compressor indicates liquid returning to the compressor. Check for

frost at the end of the freeze cycle. If liquid is returning to the compressor, the problem must be

located and corrected. See Refrigerant Charge, Thermostatic Valve and Evaporator.

Refrigerant

Refrigerant in a highpressure liquid form is fed to an expansion valve where the refrigerant is

reduced to a lowpressure liquid. Under this low pressure, the liquid will absorb heat from the

evaporator causing the liquid to change to a vapor. This vapor is the drawn into the compressor

Summary of Contents for MIM1000

Page 1: ...1 Automatic Ice maker Service manual MIM452 MIM600 MIM1000...

Page 5: ...5 Cooling System...

Page 9: ...9 Wiring Connection...

Page 12: ...12 Exploding Drawing...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...

Page 20: ...20...