3

Installation Guidelines

Note: Installation should be performed by a trained Service Technician.

For proper operation of the ice machine, the following installation guidelines must be followed.

Failure to do so may result in loss of production capacity, premature part failures, and may void all

warranties.

Ambient Operating Temperatures

Minimum Operating Temperature: 50°F (10°C)

Maximum Operating Temperature 100°F (38°C).

Note: These products are not designed for outdoor installation.

Incoming Water Supply

Minimum incoming water temperature: 40°F (5°C)

Maximum incoming water temperature: 90°F (32°C)

Minimum incoming water pressure: 15 psig

Maximum incoming water pressure: 80 psig

Note: If water pressure exceeds 80 psig, a water pressure regulator must be installed.

Drains:

Route bin drain, purge drain and water condenser drain individually to a floor drain. The

use of condensate pumps for draining water on equipment producing over 200 lbs./day is not

recommended by Manufactor. We assumes no responsibility for improperly installed equipment.

Water Filtration

A water filter system should be installed with the ice machine.

Clearance Requirements

Self contained air cooled ice machines must have a minimum of 6 inches (15cm) of clearance at the

rear, top, and sides of the ice machine for proper air circulation. Since undercounter machines

breathe from the front, top and side clearances are minimal.

Stacking

If the ice machines are to be stacked, refer to the instructions in the stacking kit. We does not

endorse stacking aircooled ice machines.

Dispenser Application

A thermostatic bin control kit must be installed if the ice machine is placed on a dispenser. A bin

top may or may not be required.

Ice Maker Maintenance

Maintenance Procedure

1. Clean the icemaking section per the instructions below. Cleaning should be performed a

minimum of every 6 months. Local water conditions may require that cleaning be performed more

often.

2. Check ice bridge thickness. Proper thickness should be 1/16-1/8’’.

3. Check water level in trough. See troubleshooting for proper water level and adjustment.

4. Clean the condenser to insure unobstructed air flow.

5. Check for leaks of any kind: Water, Refrigerant, Oil, Etc.

6. Check the bin switch for proper adjustment.

7. Check all electrical connections.

Summary of Contents for MIM1000

Page 1: ...1 Automatic Ice maker Service manual MIM452 MIM600 MIM1000...

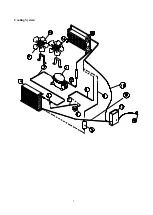

Page 5: ...5 Cooling System...

Page 9: ...9 Wiring Connection...

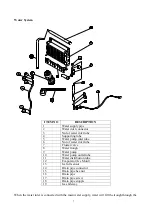

Page 12: ...12 Exploding Drawing...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...

Page 20: ...20...