2202G1JE-DA-M-N_2010.01.

3 Installation

Reciprocating Compressor M Series

3.2 Installation Works

3-2

3.2 Installation

Works

3.2.1 Unpacking

Check that there is no abnormality such as damage on the compressor.

If there are abnormalities or deficient parts on the compressor, please contact your local sales

offices or service centers immediately.

Unnecessary packing materials should be discarded according to the laws and ordinances, or

your company's rules.

3.2.2 Storage

Perform the followings to store the compressor before installation.

Store it indoors.

Infuse nitrogen gas into the compressor and seal it.

Nitrogen gas has been infused into the compressor at packing to prevent from rusting.

3.2.3 Transfer

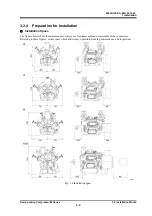

Dropping of the lifted compressor may cause death or serious injury. Do not

stand under the lifted compressor.

1.

For lifting the compressor within the safety limit, use lifting equipment and tools appropriate for the

weight of compressor.

2.

Leave sufficient space for lifting.

3.

Always check wire rope before using. Thoroughly check for kink, knot, or breakage. Do not perform

lifting before checking the wire rope. If there are any problems, do not lift until equipment has been

confirmed safe.

4.

For lifting the compressor individually, hook the wire rope on the lifting bolt of compressor.

5.

For lifting the compressor with base and motor, hook the wire rope on the lifting bolt and the base of

compressor. Do not use the lifting bolt on the motor.

6.

Check path of compressor installation to make sure it is free of obstacles.

7.

Check that the hook is above the center of gravity of the unit before lifting.

8.

Direct all the workers to stay clear of the work site before lifting.

9.

Before lifting compressor notify all workers in area of dangers during lifting process. Remove all

nonessential personal from area till lift is complete.

10.

Wind up the wire rope slowly until shortly before the compressor leaves from the ground.

11.

Remove all tension slowly until the compressor leaves the ground, and check that the compressor is

balanced. If it is tilted, lower compressor and correct the tilt. Repeat this process until the compressor

becomes level. Then wind up the wire rope.

12.

Lift the compressor slowly. If it is lifted rapidly, it may damage the lifting tools such as wire rope or a part

of the compressor.

13.

When moving the lifted compressor, always use tag line/induction rope.

14.

Do not lift the compressor over head unless absolutely necessary.

15.

Do not lower the compressor and block the passage.