2202G1JE-DA-M-N_2010.01.

3 Installation

Reciprocating Compressor M Series

3.2 Installation Works

3-8

For centering by driving the belt, strain a string on the side of flywheel and motor pulley.

Centering standard: L=1 mm or less

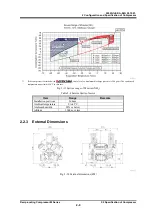

Fig. 3-3 Centering standard

2.

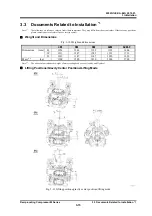

Loosen the slide base of motor, move the refrigerating machine and the pulley closer to each other, and

attach the V-belt to groove V while slacking the V-belt.

Check that the V-belt fits groove V, and pull the motor with the bolt so that the belt becomes tensioned.

Deflection = 0.008 × span length (mm) (Span length

≒

Center distance)

Fig. 3-4 Deflection

No.

Description

No.

Description

1 Tension

meter

3

Deflection

2 Center

distance

4

Span

length

Table 3-2 Amount of deflection (mm)

Table 3-3 Amount of tension load (N/belt)

Note 1:

Re-tighten the belt for the first time after 2—3 hours from the starting the operation.

Note 2:

Rotate the flywheel (pulley) to check the tension load of V-belt.

Note 3:

When the belt is under the minimum tension load, make sure that the belt does not move excessively by operation, because the

load fluctuates due to the load conditions.

Center distance (mm)

1000

1100

1200

1300

1400

1500

1600

1700

Deflection (mm)

8.6

9.5

10.4

11.3

12.2

13.0

13.9

14.9

Rotation speed of

the compressor

(rpm)

Tension load of

new belt

Tension load at

re-straining for the first

time

Tension load at

re-straining for the

second time and after

1500

95

~

105 85

~

95 60

~

70

1400

90

~

100 80

~

90 60

~

70

1300

90

~

95 75

~

85 55

~

65

1200

80

~

90 70

~

80 50

~

60

1100

75

~

85 65

~

75 50

~

60

1000

75

~

85 65

~

75 50

~

60

900

65

~

75 55

~

65 40

~

50