2202G1JE-DA-M-N_2010.01.

5 Maintenance

Reciprocating Compressor M Series

5.5 Disassembly/Assembly

5-24

5.5.4.3 Attentions for Removing the Valve Plate

Dropping of the valve plate may cause injury or damage to the compressor.

Always attach the stud bolts before performing the work.

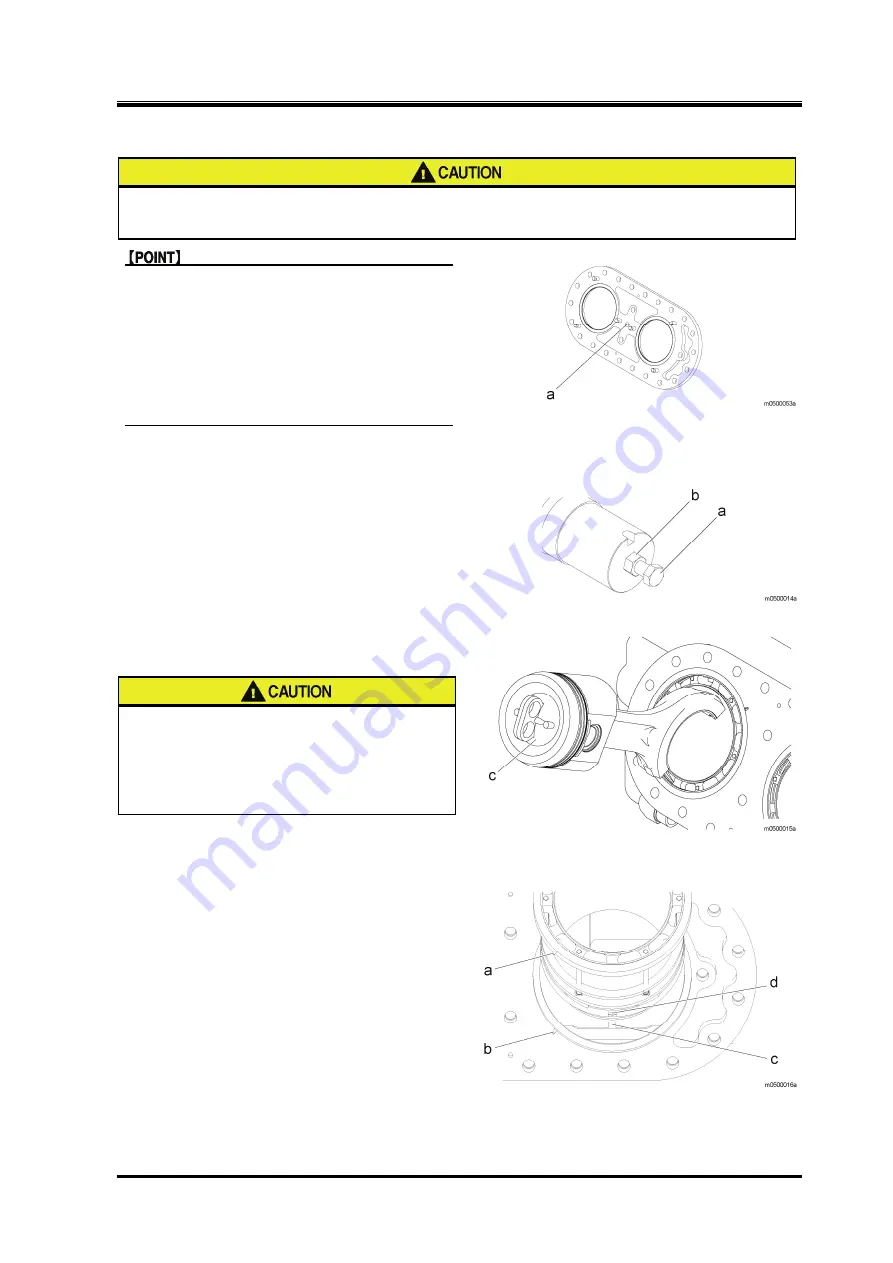

If the stud bolts that are used for removing

the head cover are already removed, attach

the stud bolts into the head cover screw bolt

holes for two sections at the top, then

remove the valve plate.

To remove the firmly–retained valve plate,

insert the valve plate screw into the service

hole (a) and tighten it.

5.5.4.4 Attentions for Removing the Piston Assembly

1.

Attach the bolt (M20) (a) and nut (b) to the

crankshaft.

Use the set bolts (M27 with fine pitch) for

62M-FM.

2.

Using the bolt (M20) (a), rotate the crankshaft so

that the piston assembly to be removed is

positioned at the bottom dead center.

3.

Remove the piston assembly using the suction

disk (c).

Verify that the suction disk is firmly

stuck to the piston assembly. If the

suction disk is not stuck firmly, the

piston assembly may fall, resulting in

hand or physical injury.

5.5.4.5 Attentions for Attaching the Cylinder Sleeve Assembly

1.

Align the sleeve positioning pin (a) with the

groove on the case (b).

2.

While keeping the pin aligned with the groove,

align the unloader push rod tab (c) with the cam

ring notch (d).

3.

To check the attachment condition of the cylinder

sleeve assembly, check the movement of the

unloader push rod (piston) when removing the

spacer used for the unloader maintenance.

(Refer to "Removal of the Spacer".)