10

e)

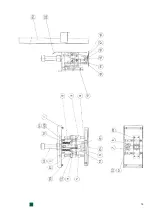

Adjust the height of the top holding jaw so that it securely holds

the second-to-last pot at the top edge of the pot.

f)

Adjust double pot receptacles 2-

3 mm below the upper pot’s

edge.

g)

Adjust the height of the pot dispenser.

The bottom edge of the last pot in the dispenser should be 10

–

20 mm above a pot already positioned in the pot receptacle.

h)

Adjust the guide rail approx.. 3-4 cm

to the lower pot’s edge

with enough play (reduce play at the drill).

Summary of Contents for TM 2400DR

Page 4: ...4 2 Structure Plan view of potting machine 2400DR back right left front ...

Page 39: ...39 9 Part list ...

Page 45: ...4 2 Functional description ...

Page 58: ...17 6 Part list ...

Page 60: ...19 ...