Installation and Operational Instructions for

EAS

®

-dutytorque Type 404_._ _400

Sizes 2

– 9

(B.4.3.1.ATEX.EN)

06/10/2016 TK/GH/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 10 of 15

Torque Adjustment (Figs. 3 and 4 / Page 4)

Set the limit torque M

G

for overload on the clutch by changing the

cup spring pre-tension on each overload element (6) according

to the Adjustment Diagram.

On the clutches the adjusting nut (9) is adjusted by turning it in

the overload element (6) using an open-end wrench.

Wrench opening values of the adjusting nut (9):

Wrench opening 19 for Sizes 2 and 3

Wrench opening 30 for Sizes 4, 5 and 6

Wrench opening 41 for Sizes 7, 8 and 9

During torque adjustment, please ensure that

all overload elements (6) on the clutch are

evenly adjusted!

Torque Adjustment:

Type 404_._0400 (Fig. 3)

Determine the limit torque M

G

for overload.

Please find the dimension “a” from the Adjustment Diagram

included in clutch delivery.

This dimension is equal to the required limit torque M

G

.

Remove the cap screws (11) and the lock washers (10), so

that the adjusting nuts (9) can be turned.

Set all overload elements (6) by turning the adjusting nut (9)

to the dimension “a” found in the Adjustment Diagram.

Secure the adjusting nuts (9) against turning using the lock

washers (10) and the cap screws (11).

Tighten the cap screws (11).

Type 404_._1400 (Fig. 4)

Determine the limit torque M

G

for overload.

Please find the dimension “a” from the Adjustment Diagram

included in clutch delivery.

This dimension is equal to the required limit torque M

G

.

Unscrew the switching disk (14) and remove the

countersunk screws (13) and distance bushings (12).

Remove the cap screws (11) and the lock washers (10), so

that the adjusting nuts (9) can be turned.

Set all overload elements (6) by turning the adjusting nut (9)

to the dimension “a” found in the Adjustment Diagram.

Secure the adjusting nuts (9) against turning using the lock

washers (10) and the cap screws (11).

Tighten the cap screws (11).

Tighten the countersunk screws (13) via the switching disk

(14) and the distance bushings (12) in the bolts (7).

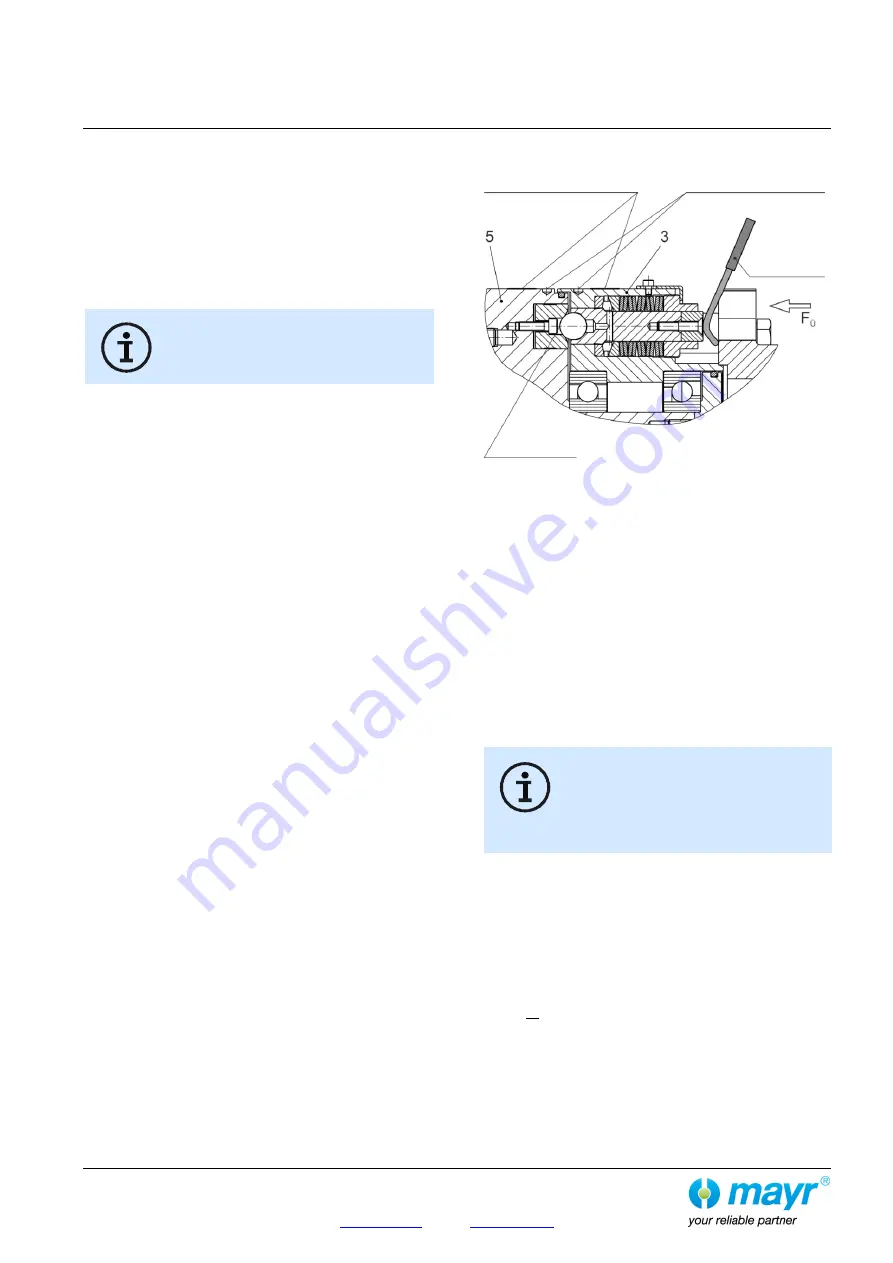

Re-engagement (Fig. 7)

Fig. 7

In order to make the clutch ready for operation again after

overload occurrence, the bolts (7) in the overload elements (6)

must be re-engaged.

Both of the yellow guideline signs for regaining the synchronous

position (due to balance quality) on the outer diameters of the

element flange (3) and the pressure flange (5) must align with

each other (Fig. 7).

Re-engagement takes place by placing axial pressure on the bolt

end of each overload element (6).

Depending on the equipment available, the accessibility of the

installation point etc., re-engagement can be carried out in the

following ways:

Manually, using a suitable tool.

By using an engagement mechanism. The engagement

procedure can also be automated using pneumatic or

hydraulic cylinders.

On Type 404_._1400 (Fig. 4, page 4), re-

engagement takes place by placing axial

pressure via the switching disk (14) on the bolt

end of each overload element. Inaccurate

application of the lever tool onto the bolt end

can lead to the switching disk (14) bending,

and thus to a risk of ignition.

The level of engagement force required is dependent on the set

limit torque for overload, and can be roughly calculated using the

following formula:

F

E

= 1.5 x M

G

[kN]

F

E

= Total engagement force of all clutch overload elements

[kN].

M

G

= Set limit torque for overload [kNm].

F

Ü

= Engagement force per overload element [kN].

F

Ü

=

F

E

n

n

= Number of overload elements

Markings for

re-engagement

Engaged

Tool

Guideline signs for

re-engagement

position