PRODUCT DESIGN

35

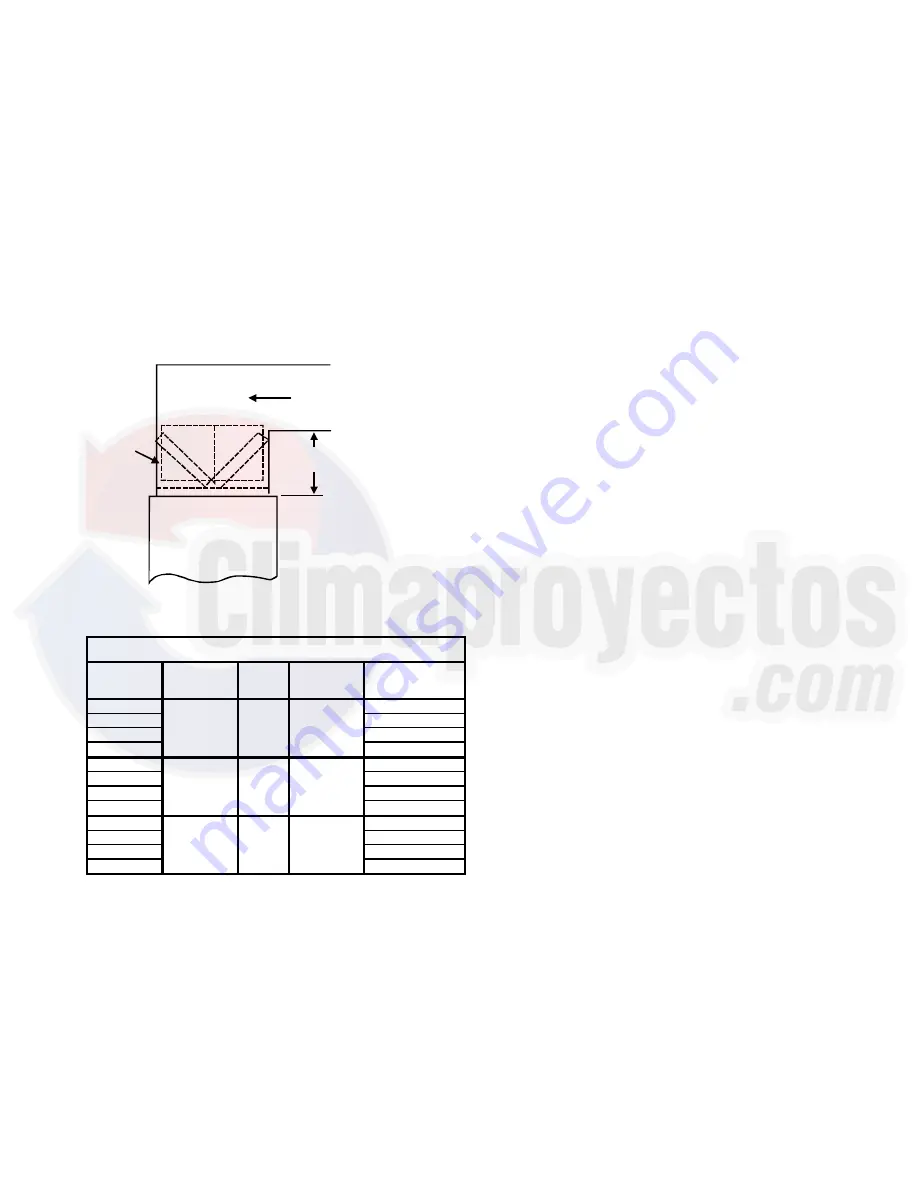

filter requirement charts for determination of the minimum

filter area to ensure proper unit performance. The following

figures show possible filter locations.

NOTE:

A ductwork

access door must be used in counterflow applications to

allow filter removal. If the filter rack is used, the side of the

plenum must be at least as tall as dimension "A" shown in

the following illustration. For dimension of "A" refer to the

following chart.

COUNTERFLOW FILTER INSTALLATION

This furnace has provisions for the installation of return air

filters at the counterflow top return. The furnace will

accommodate the following filter sizes depending on cabinet

size:

"A"

Min

Return Air

Optional

Access

Door

Cabinet

Width

Filter Area

(in

2

)

Qty.

Filter Size

(in)

Dimension "A:

(in)

14

15.1

17 1/2

14.2

21

13.0

24 1/2

11.3

14

20.4

17 1/2

19.7

21

18.8

24 1/2

17.7

14

25.5

17 1/2

25.0

21

24.3

24 1/2

23.4

15x20x1

20x20x1

25x20x1

COUNTERFLOW TOP RETURN

600

800

1000

2

2

2

Refer to Minimum Filter Area tables to determine filter area

requirement.

NOTE:

Filters can also be installed elsewhere

in the duct system such as a central return.

Horizontal Installations

Filter(s) must be installed external to the furnace casing for

horizontal installations. For most installations it is prefer-

able to use a central return with filters installed in the duct

behind the return air grill. In this way filter replacement is

relatively simple by merely removing the grille, rather than

going into the attic or crawl space.

ADDITIONAL FILTERING ACCESSORIES

External Filter Rack Kit (EFR01)

The external filter rack kit is intended to provide a location

external to the furnace casing, for installation of a perma-

nent filter on upflow model furnaces. The rack is designed

to mount over the indoor blower compartment area of either

side panel, and provide filter retention as well as a location

for attaching return air ductwork.

NORMAL SEQUENCE OF OPERATION

P

OWER

U

P

1.

115 VAC power applied to furnace.

2.

Integrated ignition control module performs internal

checks.

3.

Integrated ignition control module LED will light.

4.

Integrated ignition control monitors safety circuits con-

tinuously.

5.

Furnace awaits call from thermostat.

N

ORMAL

H

EATING

S

EQUENCE

1.

R and W thermostat contacts close, initiating a call for

heat.

2.

Integrated control module performs safety circuit

checks.

3.

The induced draft blower is energized causing pres-

sure switch contacts to close. Induced draft blower

remains energized for pre-purge period. Humidifier ter-

minals are energized with induced draft blower.

4.

Ignitor warm up begins after pre-purge is completed.

5.

Gas valve opens at end of ignitor warm up period, de-

livering gas to burners to establish flame.

6.

The control checks for a signal from the flame sensor

within seven (4) seconds after the gas valve is ener-

gized. Gas will only continue to flow if a flame signal is

present.

7.

Circulator blower is energized on heat speed following

a fixed thirty (30) second blower on delay. Electronic

air cleaner terminals are energized with circulator

blower.

8.

Furnace runs, integrated control module monitors safety

circuits continously.

9.

R and W thermostat contacts open, allowing the gas

valve to cycle off.

10. Induced draft blower is de-energized following a fifteen

(15) -second post purge. Humidifier terminals are de-

energized.

11. Circulator blower is de-energized following a selectable

heat off delay period (90, 120, 150 or 180 seconds).

Electronic air cleaner terminals are de-energized.

12. Furnace awaits next call from thermostat.

The adjustable delay-off timing allows the installer to cus-

tomize the comfort level.