54

SERVICING

NOTE:

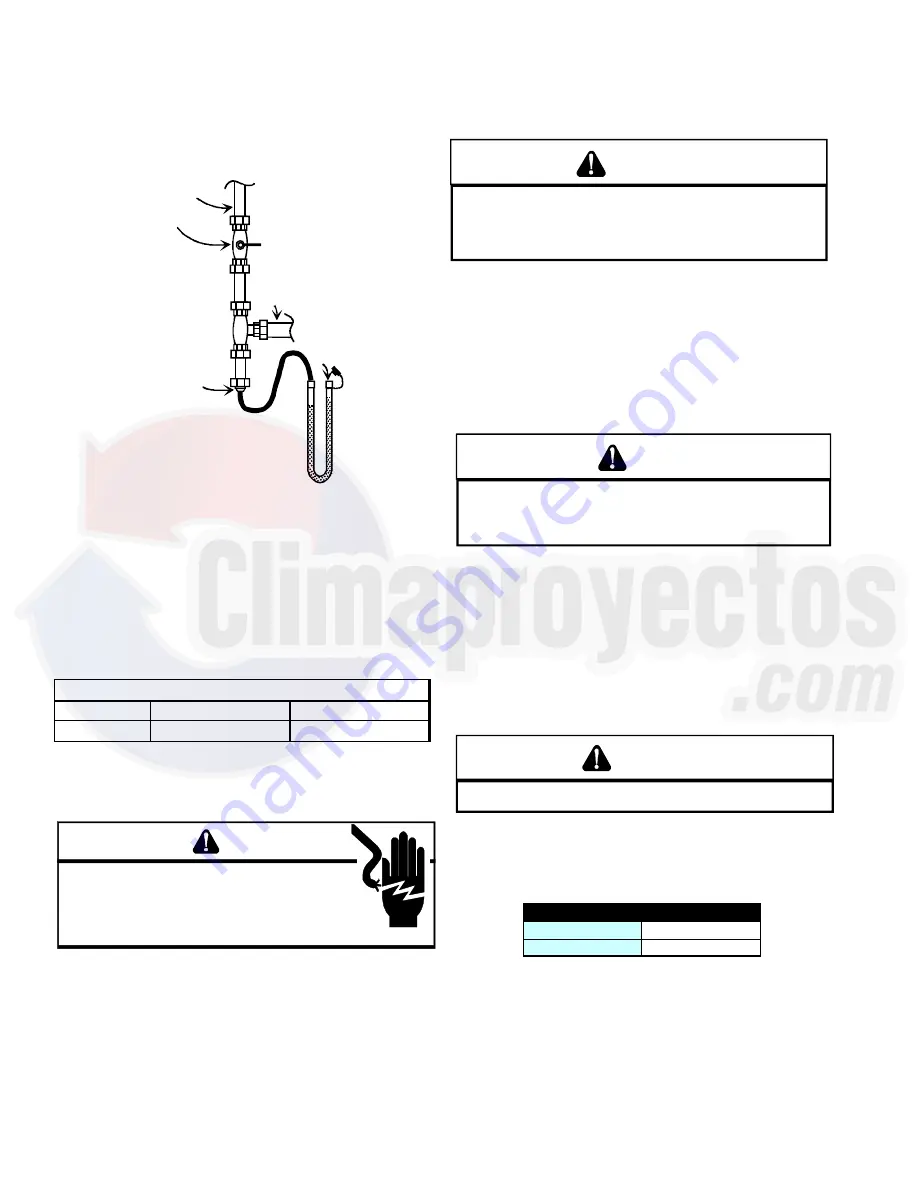

At either location, a hose fitting must be installed

prior to making the hose connection.

NOTE:

Use apapter kit #0151K00000S to measure gas pres-

sure on White-Rodgers 36J22 gas valves.

GAS LINE

GAS SHUTOFF VALVE

GAS LINE

TO FURNACE

DRIP LEG CAP

WITH FITTING

MANOMETER HOSE

MANOMETER

OPEN TO

ATMOSPHERE

Measuring Inlet Gas Pressure

(Alternate Method)

3. Turn ON the gas and electrical power supply and oper-

ate the furnace and all other gas consuming appliances

on the same gas supply line.

4. Measure furnace gas supply pressure with burners fir-

ing. Supply pressure must be within the range specified

in the following table.

Natural Gas

Minimum: 4.5" w.c.

Maximum: 10.0" w.c.

Propane Gas

Minimum: 11.0" w.c.

Maximum: 13.0" w.c.

INLET GAS SUPPLY PRESSURE

If supply pressure differs from above, make necessary ad-

justments to pressure regulator, gas piping size, etc., and/

or consult with local gas utility.

WARNING

HIGH

VOLTAGE

D

ISCONNECT

ALL

ELECTRICAL POWER AND SHUT OFF GAS

SUPPLY BEFORE SERVICING OR INSTALLING THIS UNIT.

M

ULTIPLE POWER SOURCES MAY BE PRESENT.

F

AILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

5. Disconnect manometer after turning off gas at manual

shutoff valve. Reinstall plug before turning on gas to fur-

nace.

6. Turn OFF any unnecessary gas appliances started in

step 3.

7. Turn on gas to furnace and check for leaks. If leaks are

found, repair and then reinstall burner compartment door.

8. Turn on electrical power and verify proper unit operation.

Gas Manifold Pressure Measurement and Ad-

justment

n

a

c

e

T

O PREVENT UNRELIABLE OPERATION OR EQUIPMENT DAMAGE, THE

GAS MANIFOLD PRESSURE MUST BE AS SPECIFIED ON THE UNIT

RATING PLATE.

O

NLY MINOR ADJUSTMENTS SHOULD BE MADE BY

ADJUSTING THE GAS VALVE PRESSURE REGULATOR.

CAUTION

NOTE:

Use apapter kit #0151K00000S to measure gas

pressure on White-Rodgers 36J22 gas valves.

Only small variations in gas pressure should be made by

adjusting the gas valve pressure regulator. The manifold

pressure must be measured with the burners operating. To

measure and adjust the manifold pressure, use the follow-

ing procedure.

WARNING

HIGH

VOLTAGE

D

ISCONNECT

ALL

ELECTRICAL POWER AND SHUT OFF GAS SUPPLY

BEFORE SERVICING OR INSTALLING.

1. After turning off gas to furnace at the manual gas shutoff

valve external to the furnace, remove burner compart-

ment door to gain access to the gas valve.

2. Connect a calibrated water manometer (or appropriate

gas pressure gauge) at the gas valve outlet pressure

tap. Refer to

Measuring Gas Pressure: Single Stage

Valves

figure for single stage valve outlet pressure tap

connections.

L

INE VOLTAGE NOW PRESENT

WARNING

3. Turn ON the gas and electrical power supply and oper-

ate the furnace.

4. Measure gas manifold pressure with burners firing. Ad-

just manifold pressure using the table below.

3.5" w.c.

10.0" w.c.

Manifold Gas Pressure

Natural Gas

Propane Gas

The final manifold pressure must not vary more than ± 0.3 “

w.c. from the above specified pressures. Any necessary

major changes in gas flow rate should be made by chang-

ing the size of the burner orifice.

5. White-Rodgers 36G22 Valves:

a. Back outlet pressure test screw (inlet/outlet pres-

sure boss) out one turn (counterclockwise, not more

than one turn).