14

NOTE:

Refer to

Location Requirements and Considerations

for combustion air contaminant restrictions.

The following bullets and diagram describe the restrictions

concerning the appropriate location of vent/flue pipe and com

-

bustion air intake pipe (when applicable) terminations. Refer to

Non-Direct Vent (Single Pipe) Piping

and

Direct Vent (Dual

Pipe) Piping

located in this section for specific details on

termination construction.

• All terminations (flue and/or intake) must be

located at least 12 inches above ground level or

the anticipated snow level.

• Vent terminations (non-direct and direct vent) must

terminate at least 3 feet above any forced air inlet

located within 10 feet.

NOTE:

This provision does not apply to the

combustion air intake termination of a direct vent

application.

•

The vent termination of a

non-direct

vent

application

must terminate at least 4 feet below, 4 feet

horizontally from, or 1 foot above any door,

window, or gravity air inlet into any building.

• The vent termination of a

direct vent

application

must terminate at least 12 inches from any opening

through which flue gases may enter a building (door,

window, or gravity air inlet).

• The vent termination of vent pipe run vertically

through a roof must terminate at least 12 inches

above the roof line (or the anticipated snow level)

and be at least 12 inches from any vertical wall

(including any anticipated snow build up).

• A vent termination shall not terminate over public

walkways or over an area where condensate or

vapor could create a nuisance or hazard or could

be detrimental to the operation of regulators, relief

valves, or other equipment.

• The combustion air intake termination of a direct

vent application should not terminate in an area

which is frequently dusty or dirty.

NOTE:

In Canada, the current edition of CAN/CSA B149.1-

15 takes precedence over the preceding termination

restriction.

Canadian Vent Pipe & Combustion Air Pipe

Requirements

All installations in Canada must conform to the require-

ments of CAN/CSA B149.1 -15 code. All vent components,

including primer and cement, must be listed to ULC S636.

The certified pipe and fittings should be clearly marked with

the ULC standard “S636”. The primer and cement used must

be of the same manufacturer as the vent system. For Royal

Pipe System 636; use GVS-65 Primer (Purple) and GVS-65

PVC Solvent Cement. For IPEX System 636, use PVC/CPVC

Primer, Purple or clear. Use PVC Solvent Cement (Gray).

For Canadian installations, ABS may be used as a combus-

tion air pipe only. ABS is not an approved vent material in

Canada. If ABS is used as a combustion air pipe, it must be

CSA certified. Always follow the manufacturer’s instructions

in the use of primer and cement. Do not use primer and

cement around potential sources of ignition. Do not use

primer or cement beyond its expiration date.

The safe operation, as defined by ULC S636, of the vent

system is based on following these installation instructions,

the vent system manufacturer’s installation instructions,

and proper use of primer and cement. It is recommended

under this standard, that the vent system be checked

once a year by qualified service personnel. All fire stops

and roof flashings used with this system must be UL listed.

Acceptability under CAN/CSA B149.1-15 is dependent upon

full compliance with all installation instructions. Consult

the authority having jurisdiction (gas inspection authority,

municipal building department, fire department, etc.) be

-

fore installation to determine the need to obtain a permit.

*IPEX System 636™ is a trademark of IPEX Inc.

Carefully follow the pipe manufacturers’ instructions for cutting,

cleaning, and solvent cementing PVC and/or ABS.

The vent can be run through an existing unused chimney provid-

ed the space between the vent pipe and the chimney is insulated

and closed with a weather-tight, corrosion-resistant flashing.

Standard Furnace Connections

It is the responsibility of the installer to ensure that the piping

connections to the furnace are secure, airtight, and adequately

supported.

Vent/Flue Pipe

The vent pipe outlet is sized to accept 2” pipe. Secure vent/

flue pipe directly into the furnace fitting with the appro

-

priate glue. Alternately, a small section of 2” pipe may be

glued in the furnace socket and a rubber coupling installed

to allow removal for future service. Combustion Air and

Vent piping should be routed in a manner to avoid contact

with refrigerant lines, metering devices, condensate drain

lines, etc. If necessary, clearances may be increased by

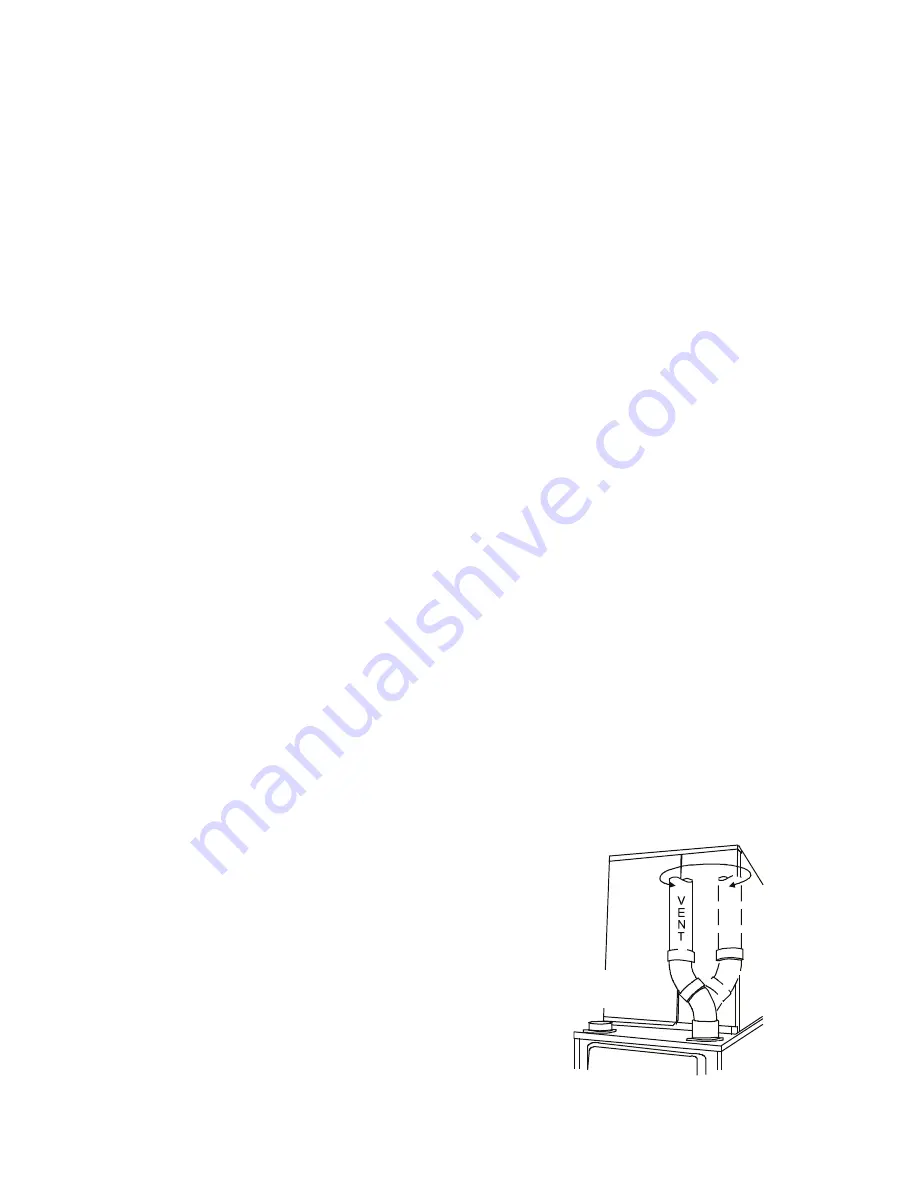

creating an offset using two 45 degree elbows (Figure 8A).

45 DEGREE

ELBOWS

Increased Clearance Configuration

Figure 8A