16

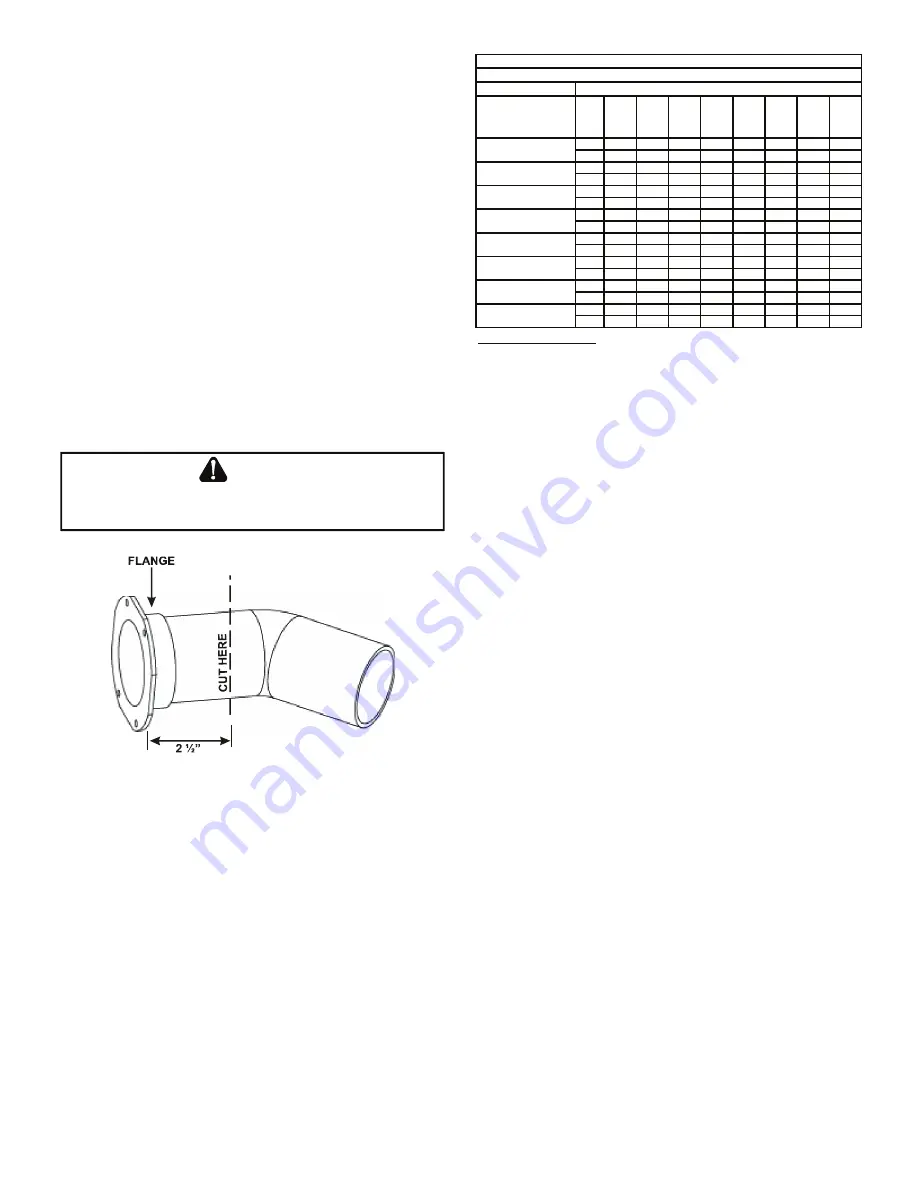

Alternate Vent/Flue Location

The alternate vent/flue location is the large hole directly

in

line with the induced draft blower outlet. To use the al-

ternate vent/flue location refer to the following steps and

the “Alternate Vent/Flue Location” figure. This option is

not available with counterflow models.

NOTE: In the horizontal left installation position, a means

of condensate collection must be provided to keep vent

pipe condensate from entering the draft inducer housing.

If the vent drain elbow is eliminated from the installation,

an RF000142 kit must be used.

1. Remove the four screws from the vent pipe flange

on top the furnace.

2. Remove the internal elbow and vent pipe

3. Cut 2 1/2” from the flange .

4. Remove plastic plug in line with the inducer outlet

5. Install cut end of the flanged section and connect to

inducer with rubber coupling supplied with furnace.

6. Install screws removed in step 1 securing flange to

cabinet.

B

E

SURE

NOT

TO

DAMAGE

INTERNAL

WIRING

OR

OTHER

COMPONENTS

WHEN

REINSTALLING

COUPLING

AND

SCREWS

.

CAUTION

Figure 10

Alternate Combustion Air Provision

(Upflow / Horizontal models only)

When using the alternate venting location, either in a hor

-

izontal left side down installation or a vertical installation

using down – venting, an alternate combustion air opening

can be used. A locating dimple is located on the right side

of the furnace cabinet. The locating dimple is 1 7/8” mea-

sured from the front edge of the cabinet in line with the

knock out. To use the alternate combustion air location:

1. Remove screws and combustion air flange from

cabinet.

2. Insert cabinet plug in unused combustion air hole.

3. Drill a pilot hole at the cabinet dimple (size dictated

by knockout tool used).

4. Use a knockout tool to create a 3” diameter hole

5. Install combustion air flange and secure with screws

removed in step one.

MODEL

PIPE

SIZE

(4)

1

2

3

4

5

6

7

8

2

75

70

65

60

55

50

45

40

3

114

107

100

93

86

79

72

65

2

55

50

45

40

35

30

25

20

3

127

120

113

106

99

92

85

78

2

^

30

25

20

15

10

5

N/A

N/A

3

^

72

65

58

51

44

37

30

23

2

^

30

25

20

15

10

5

N/A

N/A

3

^

72

65

58

51

44

37

30

23

2

^

40

35

30

25

20

15

10

5

3

72

65

58

51

44

37

30

23

2

60

55

50

45

40

35

30

25

3

168

161

154

147

140

133

126

119

2

30

25

20

15

10

5

N/A

N/A

3

113

106

99

92

85

78

71

64

2

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3

65

58

51

44

37

30

23

16

7,000 ft altitude or above use 3" pipe

^

*MES920402BN - add 20' of 2" pipe for upflow position

^

*MES920803BN - add 10' of 2" pipe for upflow position, add 66' of 3" pipe for upflow position

^

*MES920804CN - add 25' of 2" pipe for upflow position, add 58' of 3" pipe for upflow position

^ *MES920805CN - add 15' of 2" pipe for upflow position, add 58' of 3" pipe for upflow position

*MES921005CN

*MES921205DN

*MES92 Direct Vent

(2-Pipe)

and Non-Direct Vent

(1-Pipe) (6)

Maximum Allowable Length of Vent/Flue Pipe

(1) (2)

Number of Elbows

(3) (5)

*MES920603BN

*MES921004CN

*MES920403AN

*MES920803BN

*MES920804CN

*MES920805CN

1. Maximum allowable limits listed on individual lengths

for inlet and flue and NOT a combination.

2. Minimum requirement for each vent pipe if five (5)

feet in length and one elbow/tee.

3. Tee used in the vent/flue termination must be

included when determining the number of elbows

in the piping system.

4. 2 ½” or 3” diameter pipe can be used in place of 2”

diameter pipe.

5. Increased Clearance Configuration using (2) 45 deg.

elbow.

6. One 90° elbow should be secured to the combustion

air intake connection.