Troubleshooting

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power before servicing, unless

testing requires power.

16023155

©2005 Maytag Services

8

displayed. A code generated during or after the

current cycle will be displayed with the rightmost dot

“.”

turned

“

ON

”

.

Access Other Features

While a diagnostic code is displayed, if the

Normal

Cycle

key is pressed and held, the machine will

display the number of cycles since the diagnostic

code occurred. To clear the diagnostic list press the

Quick Wash

and

Whites

key while viewing the list.

The cycle count for each diagnostic code will also be

reset to 0, but not the machine cycle count.

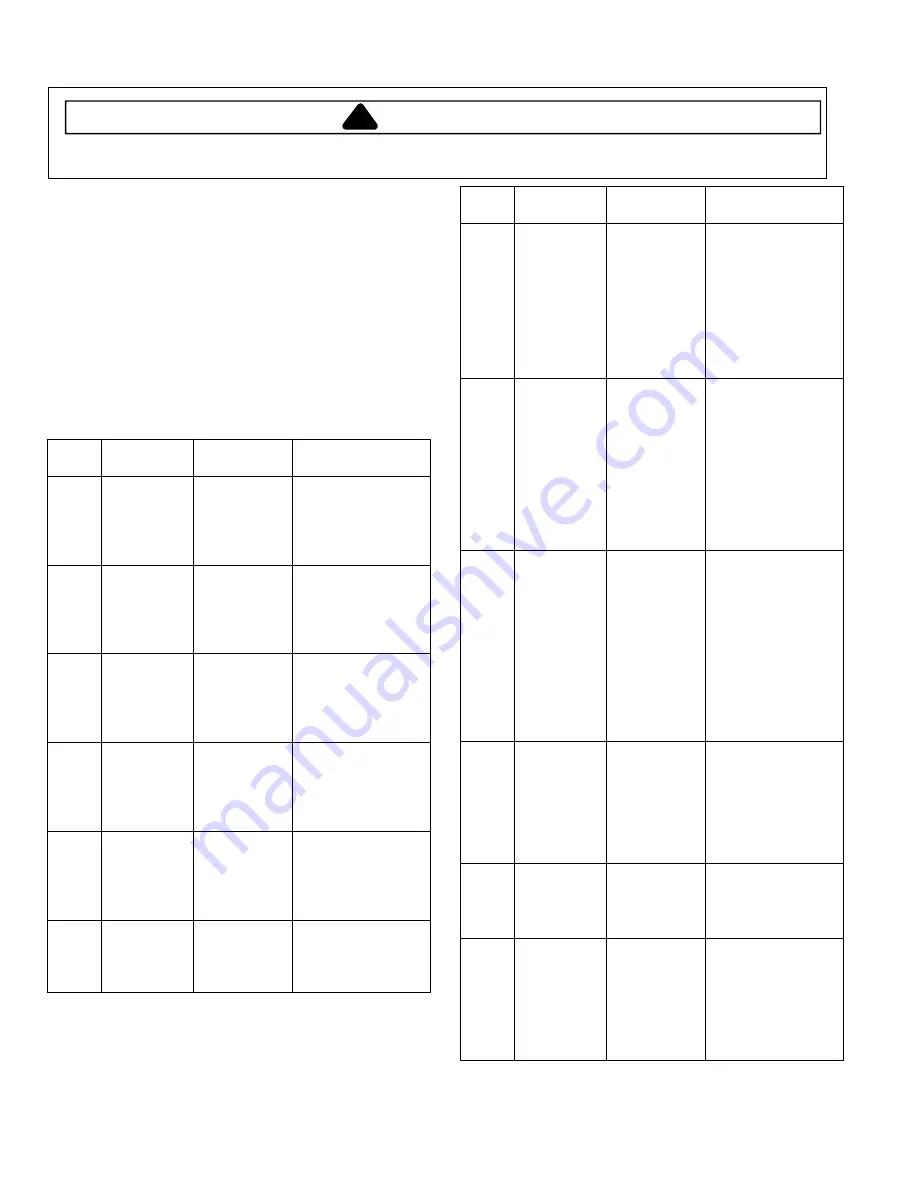

Diagnostic Codes

Diag.

Code

Description

Trigger

Action to be

taken

1 No

Drain

The water

level fails to

drop below

the Low level

before a spin

Displays

"nd"

Go to "

Will Not

Drain

"

Troubleshooting

Section

2

The lid fails

to unlock

Lid failed to

unlock after

multiple

attempts

Displays

"LO"

Go to "

Will Not

Unlock"

Troubleshooting

Section

3

No Fill

Total fill 14

minutes

exceeded.

Displays "

nF

"

Go to "

No Water

Fill

"

Troubleshooting

Section

4

The lid fails

to lock

Lid failed to

lock after 11

attempts

Displays "

FL

"

Go to "

Will not

unlock

"

Troubleshooting

Section

5

Continuous

unbalanced

circuit. Out

of balance

circuit

See section

for unbal.

loads.

(During spin

only)

Displays

"UC"

Go to "

Wet

Clothes

"

Troubleshooting

Section

6

Locked

Rotor forcing

a shut down.

Locked rotor

is still locked

after 10

attempts.

Displays

"Lr"

Go to "

Motor

Control Board

Output Test

"

Diag.

Code

Description

Trigger

Action to be

taken

8

Water level

sensor fault.

Input signal

from water

level Sensor

is out of

range,

Washer will

beep and

pause the

wash cycle.

Displays "LE" Go to

“No water fill

troubleshooting”.

10

Unbalance

or cabinet hit

detected

during final

spin, which

prevented

the spinner

from

exceeding

500 rpm

Less than 500

rpm due to an

unbalanced

load.

LED – Will display

“

ub

”

Go to "

Wet

Clothes

"

Troubleshooting

Section"

11

Will not

remember

machine

settings

Difficulty in

reading

memory

Go to "

Clear

diagnostic codes

"

Disconnect and

reconnect the

washer power cord

at power supply

outlet.

If condition still

exists, replace

machine control

board.

15 Stuck

Key

Detected a

key pressed

more than 75

seconds. The

key is

assumed to

be stuck.

Go to "

Membrane

Pad Check

"

Check connection

of keypad to control

board.

Replace console if

necessary.

16

High speed

not achieved

due to

torque.

Speed less

than 400 rpm

during a main

wash cycle.

Go to "

Wet

Clothes

"

Troubleshooting

Section"

17

The lid was

not opened

after

completed

wash cycles.

Did not sense

lid open after

the last three

completed

cycles.

LED – Will display

“

od

”

Customer may have

tried to repeat wash

cycle without

opening the lid. Go

to "

Lid Lock Test

"