42

MAYTAG GAS WATER HEATERS

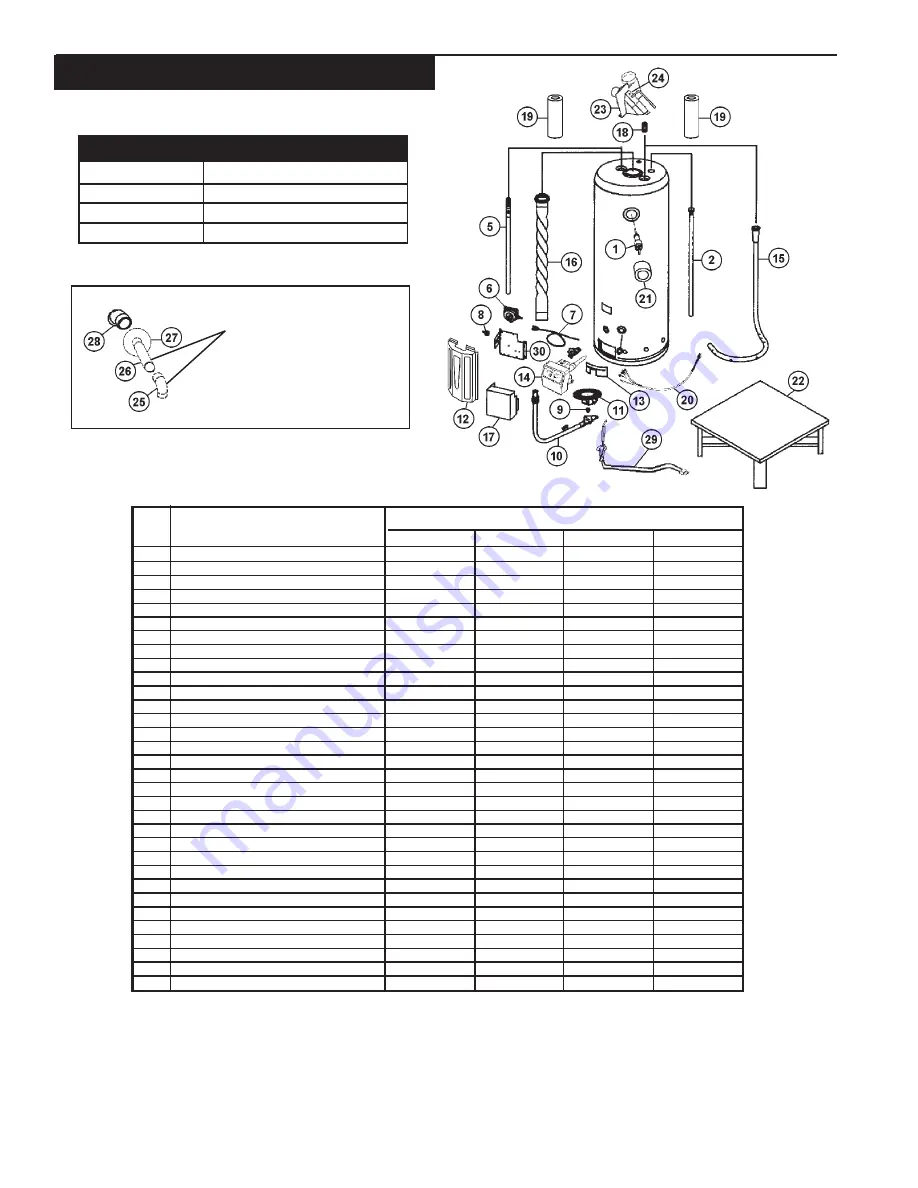

REPAIR PARTS LIST

Now that you have purchased this gas water heater, should a need

ever exist for repair parts or service, simply

call Maytag Customer

Service at 1-800-788-8899 for an authorized servicer

. Be sure to

provide all pertinent facts when you call or visit.

THIS IS A REPAIR PARTS LIST, NOT A PACKING LIST.

The model number of this gas water heater will be found on the model

rating plate located near the gas control valve.

When ordering repair parts, always give the following information:

•

Model number

•

Serial Number

•

Part Description

•

Part Number

MODEL NO’S

HRN11250P

50 Gallon Natural Gas

HRN31250P

50 Gallon Natural Gas

HRP11250P

50 Gallon Propane Gas (L.P.)

HRP31250P

50 Gallon Propane Gas (L.P.)

* Not Shown.

Key

Model Numbers

No.

Part Description

HRN11250P

HRN31250P

HRP11250P

HRP31250P

1

Temperature-Pressure Relief Valve

66001700

66001700

66001700

66001700

2

Primary Anode Rod

66001020

66001020

66001020

66001020

3

Drain Valve

66001015

66001015

66001015

66001015

*4

Drain Valve Washer

(17/32” x 13/64” x 1/8” thick)

66001021

66001021

66001021

66001021

5

Secondary Anode Rod w/Heat traps

66001898

66001898

66001898

66001898

6

Pressure Switch

66001368

66001368

66001368

66001368

7

Power Cord

66001372

66001372

66001372

66001372

8

On/Off Switch

66001247

66001247

66001247

66001247

9

Burner Orifice (Drill Size)

66001538

66001638

66001540

66001515

10

Manifold

66001659

66001659

66001659

66001659

11

Burner

66001027

66001027

66001027

66001027

12

Outer Door

66001190

66001190

66001190

66001190

13

Inner Door

66001029

66001029

66001029

66001029

14

Gas Control Valve (Natural)

66001527

66001527

- - - - - - - -

- - - - - - - -

14

Gas Control Valve (Propane{L.P.])

- - - - - - - -

- - - - - - - -

66001528

66001528

15

Dip Tube

66001052

66001052

66001052

66001052

16

Flue Baffle

66001399

66001399

66001399

66001399

17

Junction Box Cover

66001899

66001899

66001899

66001899

18

Inlet Nipple w/Heat Traps

66001707

66001707

66001707

66001707

19

Pipe Insulation (2 ea.)

66001755

66001755

66001755

66001755

20

Wiring Harness

66001526

66001526

66001526

66001526

21

T & P Insulation

66001709

66001709

66001709

66001709

22

Water Heater Stand

66001243

66001243

66001243

66001243

23

Blower/ Draft Hood Ass’y

66001366

66001366

66001366

66001366

24

Venting Switch

66001367

66001367

66001367

66001367

25

3” or 2” Schedule 40 90

o

Elbow

- - - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

26

3” or 2” Schedule 40 Vent Pipe

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

27

Wall Collar

66001262

66001262

66001262

66001262

28

3” PVC Vent Terminal

66001255

66001255

66001255

66001255

29

Hot Surface Ignition Ass’y

66001525

66001525

66001525

66001525

30

Mounting Bracket

66001896

66001896

66001896

66001896

*31

Manual

66001897

66001897

66001897

66001897

PCV, ABS OR CPVC ITEMS

FOR ALL MODELS SUPPLIED

LOCALLY

Summary of Contents for HRN11240P

Page 3: ...3 SAFETY PRECAUTIONS ...

Page 45: ...45 NOTES ...

Page 46: ...46 NOTES ...

Page 47: ...47 NOTES ...