Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to dryer before servicing, unless

testing requires power.

16026881

September

2006

RPL 16026540

©2006 Maytag Services

4

LED/Switch Check

While in

Service

Mode, pressing the

Chime

and

Wrinkle Prevent

keys for 3 seconds, will start a

LED/Switch Test. To exit the test at any point, press

the same keys again for 3 seconds or press the

OFF

key to exit Service Mode.

Perform the check by pressing the keys which toggle

the LED’s on and off.

All switch pads must be pressed within 5 minutes for

this test to pass.

PA

will be displayed for five (5)

seconds once all switch pads have been pressed and

this test is completed. Following 10 seconds of

inactivity at any point, the test will exit without any

display. The

Power Off

switch pad must be pressed

twice within thirty (30) seconds to cancel this test.

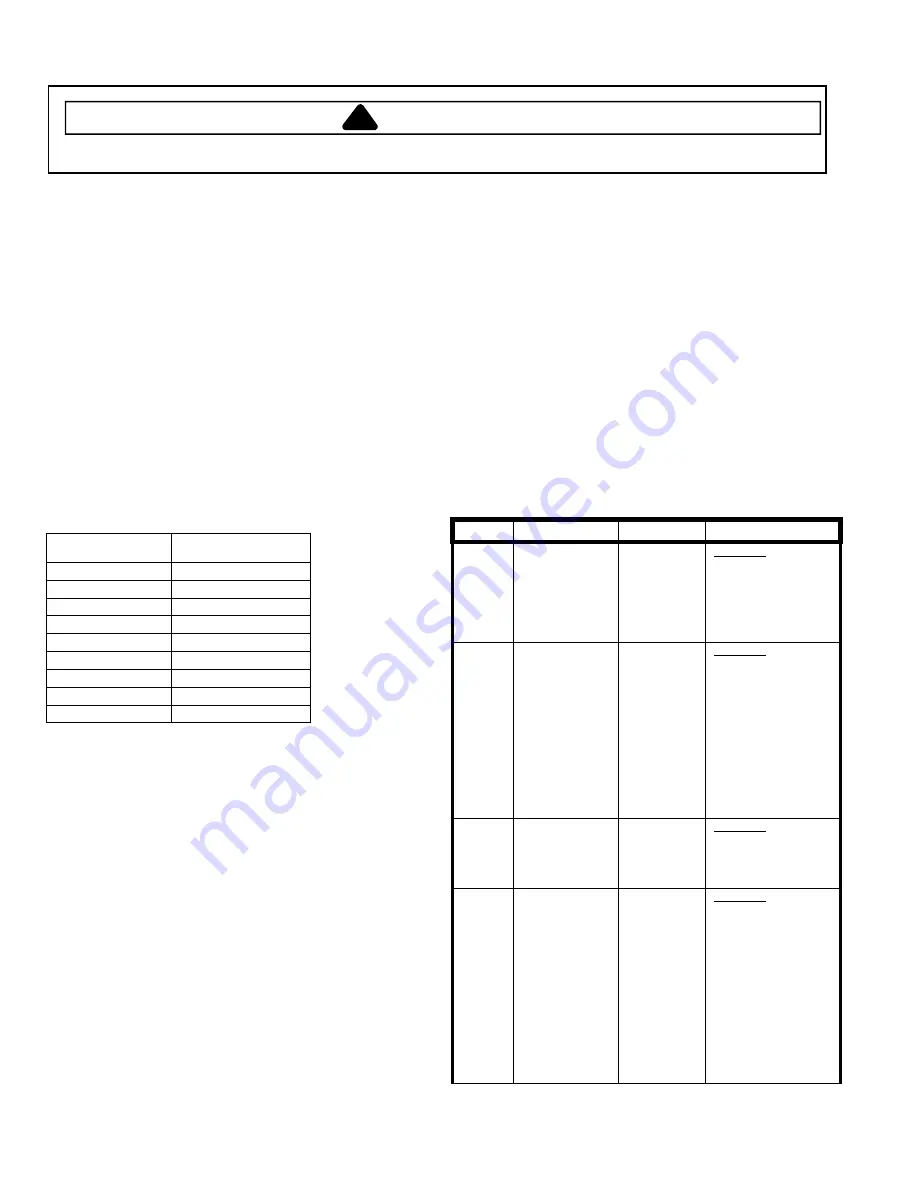

Switch Action

Wrinkle Prevent Press once

Chime Press

once

Adjust Time

Press once

Time

Press four times

Temperature Press

twice

Dryness Level

Press twice

Selector Knob

Rotate 1 position

Start Pause

Press once

Off Press

once

Diagnostic Codes

The Diagnostic Codes are identified when the severity

level of the abnormality detected is higher and service

may be required.

When a problem with the dryer is detected a

Diagnostic Code is assigned, and can be displayed.

The Control Board will not log multiple same codes

per cycle; however, it will log as many Diagnostics as

possible for the machine to continue running.

Access Diagnostic Codes by entering the Service

Mode and pressing

Wrinkle Prevent

.

A

d

will be

displayed.

Rotate the Cycle Selector Knob in either direction to

step through the list of codes one code at a time.

Once an initial direction is selected by the user (either

Clockwise or Counterclockwise), subsequent

movements of the knob in the same direction will

show older codes. If the user changes direction and

turns the knob in the opposite direction, the more

recent code will be displayed.

While a diagnostic code is displayed, if the

Start/Pause

button in the center of the Rotary Cycle

Selector is pressed and held, the machine will display

the number of cycles ago the diagnostic code

occurred. When the

Start/Pause

button is released,

the diagnostic code is again displayed

.

Clearing Diagnostic Codes

To clear the diagnostic code list press the

Sensor Dry

Level

and

Time

keypads together for 3 seconds while

viewing the list. The cycle count for each diagnostic

code will be reset to 0, but not the machine cycle

count.

Diagnostic Codes

Code Description Trigger

Action

Taken

1

Dryer

Thermistor

Short Sensed

The

Thermistor

resistance is

very low.

Check for:

-

Clogged

lint

screen.

-

Restricted

vent

system.

-

Check

Thermistor

resistance.

2

Thermistor

Open Sensed

The

Thermistor

resistance is

very high

Check for:

-

Low

ambient

temperature in

room (Below

50

º

F/10

º

C).

-

Outside

vent

damper is stuck

open in wintertime.

-

Loose or open

wire terminals.

-

Check

Thermistor

resistance.

3

Door Circuit

Failure

Invalid state

for more

than 256

milliseconds

Check for:

-

Loose or open

wire terminals in

Door Sense

circuit.

4

Possible motor

transistor error

If either

motor

transistor is

seen open or

shorted

during

startup

Check for:

-

Loose

connections

in motor circuit.

-

Run

System

Check Mode and

check the motor

relay function.

-

If relay functions,

disregard the

diagnostic code.

-

If relay does not

function, replace

machine control

board.