8

Maytag Co.

113062 - 17

Provisions for adequate air supply must be provided as noted

in this manual (refer to Fresh Air Supply Requirements

section).

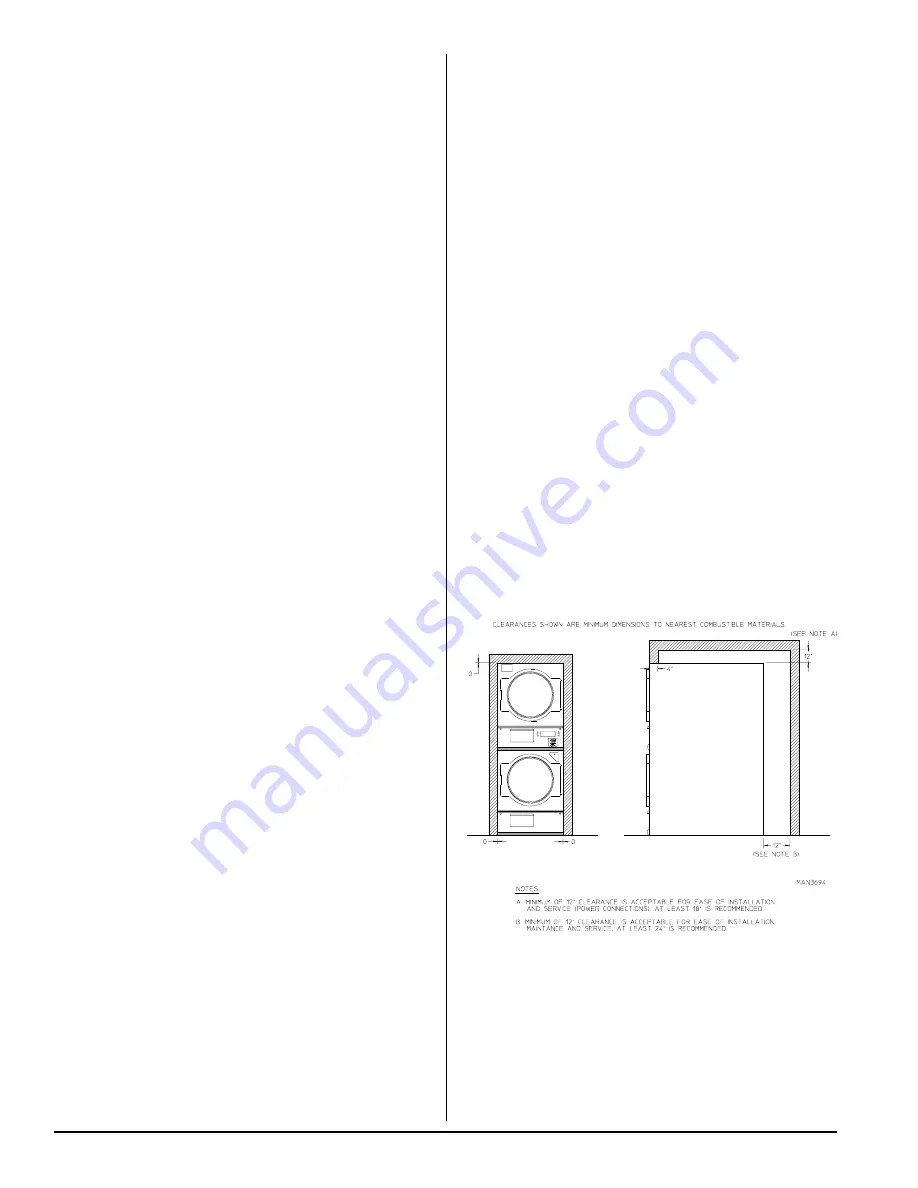

Clearance provisions must be made from noncombustible

construction as noted in this manual (refer to Dryer Enclosure

Requirements section).

Even though a 12-inch clearance is acceptable, it is

recommended that the rear of the dryer be positioned

approximately 2 feet away from the nearest obstruction, i.e.,

wall, for ease of installation, maintenance, and service. (Refer

to the illustration below.)

Provisions must be made for adequate clearances for

servicing and for operation as noted in this manual (refer to

Dryer Enclosure Requirements section).

Dryer must be exhausted to the outdoors in an area where

correct exhaust venting can be achieved as noted in this

manual (refer to Exhaust Requirements section).

Dryer must be located in an area where correct exhaust venting

can be achieved as noted in this manual (refer to Exhaust

Requirements section).

The dryer must be installed with a proper exhaust duct

connection to the outside.

The dryer must be installed with provisions for adequate

combustion and make-up air supply.

CAUTION:

This dryer produces combustible lint and must

be exhausted to the outdoors. Every six months, inspect

the exhaust ducting and remove any lint build up.

IMPORTANT:

Dryer must be installed in a location/

environment, which the ambient temperature remains

between 40° F (4.44° C) and 130° F (54.44° C).

IMPORTANT:

Dryer should be located where a minimum

amount of exhaust duct will be necessary.

Installation Procedures _______________

Installation should be performed by competent technicians

in accordance with local and state codes. In the absence of

these codes, the installation must conform to applicable

American National Standards: ANSI Z223.1-LATEST EDITION

(National Fuel Gas Code) or ANSI/NFPA NO. 70-LATEST

EDITION (National Electrical Code) or in Canada, the

installation must conform to applicable Canadian Standards:

CAN/CGA-B149.1-M91 (Natural Gas) or CAN/CGA-B149.2-

M91 (L.P. Gas) or LATEST EDITION (for General Installation

and Gas Plumbing) or Canadian Electrical Codes Parts 1 &

2 CSA C22.1-1990 or LATEST EDITION (for Electrical

Connections).

Unpacking/Setting Up _________________

Remove protective shipping material (i.e., plastic wrap and

optional shipping box) from dryer.

NOTE:

The access keys for the service doors are included

in the information packet shipped in the tumbler. These

keys should be removed and put in a safe place yet made

accessible because some will be needed throughout

various phases in the installation of the dryer.

Dryers are shipped with a coin box and coin box faceplate

only. The coin box lock is not included and must be purchased

elsewhere or the lock can be ordered as a parts order from

the manufacturer.

The dryer can be moved to its final location while still attached

to the skid or with the skid removed. To unskid the dryer,

locate and remove the four bolts securing the base of the

dryer to the wooden skid. Two are at the rear of the base, and

two are located in the front. Once the bolts are removed,

slide the dryer off the skid.

With the skid removed, to make it easier to slide the dryer into

its final position, slightly lower all four leveling legs, so that

the dryer will slide on the legs instead of the base frame. The

dryer is equipped with four leveling legs, one at each corner

of the dryer base. The hex head adjustment bolts for the two

front leveling legs are located directly behind the lower access

door, and the rear two adjustments are directly behind the

lower rear back (guard) panel.

Location of the Dryer _________________

Before installing the dryer, be sure the location conforms to

local codes and ordinances. In the absence of such codes

or ordinances the location must conform with the National

Fuel Gas Code ANSI.Z223.1 LATEST EDITION, or in Canada,

the installation must conform to applicable Canadian

Standards: CAN/CGA-B149.1-M91 (Natural Gas) or CAN/

CGA-B149.2-M91 (L.P. Gas) or LATEST EDITION (for General

Installation and Gas Plumbing).

The dryer must be installed on a sound level floor capable of

supporting its weight. Carpeting must be removed from the

floor area that the dryer is to rest on.

IMPORTANT:

“The dryer must be installed on

noncombustible floors only.”

The dryer must not be installed or stored in an area where it

will be exposed to water or weather.

The dryer is for use in noncombustible locations.