7. BAROMETRIC DAMPER CONTROL.

The barometric damper control, also known as a draft

regulator, is used on conventional chimney venting only.

This control automatically maintains a constant negative

pressure in the furnace to obtain maximum efficiency. It

ensures that proper pressures are not exceeded. If the

chimney does not develop sufficient draft, the draft

control cannot function properly. The draft regulator,

when installed should be in the same room or enclosure

as the furnace and should not interfere with the

combustion air supplied to the burner. The control should

also be located near the furnace flue outlet and installed

according to the instructions supplied with the regulator.

The flue outlet pressure (measured between the furnace

and draft regulator, or the oil burner mounting plate over-

fired draft access port. fig. 2) should be set to -0.02 in.

w.c.

9.

FAN TIMER BOARD AND LIMIT CONTROL

(FIG. 4) (page 19)

The

United Technologies 1168-1 ECM

(POF1HD140AVFA and POF1HD091AVFA)

tap board

has an adjustable fan on/off delay that must be adjusted

in accordance with the furnace input rating (nozzle size).

Refer to Table A-10 (pg 15) for ECM blower set-up.

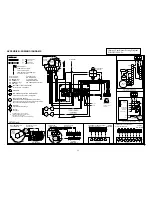

10. ELECTRICAL CONNECTIONS

The furnace is listed by the Canadian Standards

Association under the NRTL (North American) Standard.

It is factory wired and requires minimal field wiring. All

field wiring should conform to CAN/CSA C22.1 Canadian

Electrical Code, Part 1, and by local codes, where they

prevail. In the United States, the wiring must be in

accordance with the National Fire Protection Association

NFPA-70, National Electrical Code, and with local codes

and regulations.

The furnace should be wired to a separate and dedicated

circuit in the main electrical panel; however, accessory

equipment such as electronic air cleaners and

humidifiers may be included on the furnace circuit.

Although a suitably located circuit breaker can be used

as a service switch, a separate service switch is

advisable. The service switch is necessary if reaching

the circuit breaker involves becoming close to the

furnace, or if the furnace is located between the circuit

breaker and the means of entry to the furnace room. The

furnace switch (service switch) should be clearly marked,

installed in an easily accessible area between the

furnace and furnace room entry, and be located in such a

manner to reduce the likelihood that it would be mistaken

as a light switch or similar device.

The power requirement for the POF1HD140AVFA and

POF1HD091AVFA models is: 120 VAC, 1 Ø, 60 Hz.,

12A.

Accessories requiring 120 VAC power sources such as

electronic air cleaners and humidifier transformers may

be powered from the electronic

fan timer board

where provisions have been made for connections,

but should have their own controls. Do not use the

direct drive motor connections as a power source,

since there is a high risk of damaging the

accessories by exposure to high voltage from the

auto-generating windings of the direct drive motor.

Thermostat wiring connections and air conditioning

contactor low voltage connections are shown in the

wiring diagrams in Appendix B. Some micro-

electronic thermostats require additional controls

and wiring. Refer to the thermostat manufacturer's

instructions.

The thermostat should be located approximately 5

feet above the floor, on an inside wall where there is

good natural air circulation, and where the

thermostat will be exposed to average room

temperatures. Avoid locations where the thermostat

will be exposed to cold drafts, heat from nearby

lamps and appliances, exposure to sunlight, heat

from inside wall stacks, etc.

The thermostat heat anticipator should be adjusted

to the amperage draw of the heating control circuit

as measured at the "R" and "W" terminals of the

thermostat. To reduce the risk of damaging the heat

anticipator, do not measure this current with the

thermostat connected to the circuit. Measure the

amperage by connecting an ammeter between the

two wires that will connect to the thermostat "R" and

"W" terminals.

11. HUMIDIFIER

A humidifier is an optional accessory available

through most heating supplies outlets. Installation

should be carried out in accordance with the

humidifier manufacturer's installation instructions.

Water or water droplets from the humidifier should

not be allowed to come into contact with the furnace

heat exchanger. Do not use direct drive motor

connections as a source of power for 120 VAC

humidifiers and humidifier transformers.

12. PIPING INSTALLATION

The entire fuel system should be installed in

accordance with the requirement of CAN/CSA B-

139, and local regulations. Use only an approved

fuel oil tanks piping, fittings and oil filter.

In the United States the installation must be in

accordance with NFPA No. 31 and local codes and

authorities.

Install the oil filter as close to the burner as possible.

For further details of the oil supply tank and piping

requirements, please refer to the instructions and

illustrations in the oil burner and oil pump

instructions shipped with the furnace.

5

Summary of Contents for POF1HD091AVFA

Page 30: ...30...

Page 33: ...33...

Page 36: ...NOTES Nordyne Inc 8000 Phoenix Parkway O Fallon Missouri 63368 766B 0909...