9

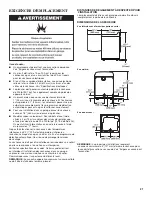

INSTALL LEVELING LEGS

2.

Screw in leveling legs

Examine leveling legs. Using a wrench, screw legs into leg

holes until foot flange touches the base. Foot is fully installed

when bottom of foot is approximately 1/2" (13 mm) from

bottom of dryer.

Now stand the dryer on its legs. Slide the dryer until it is

close to its final location. Leave enough room for electrical

connection and to connect the exhaust vent.

Prepare dryer for leveling legs

1.

To avoid damaging floor, use a large flat piece of cardboard

from dryer carton; place under entire dryer. Firmly grasp

dryer body (not console panel) and gently lay dryer down on

cardboard.

IMPORTANT:

If laying dryer on its back, use the cardboard

corner posts the dryer was packed with to avoid damaging

the back of the dryer. Lay the dryer on its side if you do not

have the cardboard corner posts the dryer was packed with.

Flange

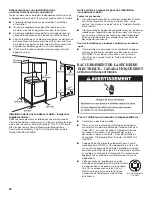

Connect gas supply to dryer

1.

Remove red cap from gas pipe. Using a wrench to tighten,

connect gas supply to dryer. Use pipe-joint compound

on threads of all non-flared male fittings. If flexible metal

tubing is used, be sure there are no kinks.

NOTE:

For LP gas connections, you must use pipe-joint

compound resistant to action of LP gas. Do not use

TEFLON

®†

tape.

MAKE GAS CONNECTION

A

B

Non-flared

male fitting

Flared

male fitting

Open shut-off valve

3.

Open shut-off valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution.

Bubbles will show a leak. Correct any leaks found.

A

B

Open valve

Closed valve

A

B

C

D

Plan pipe fitting connection

2.

A combination of pipe fittings must be used to connect dryer

to existing gas line. A recommended connection is shown.

Your connection may be different, according to supply line

type, size, and location.

A. 3/8" flexible gas connector

B. 3/8" dryer pipe

C. 3/8" to 3/8" pipe elbow

D. 3/8" pipe-to-flare adapter fitting