BODY STRUCTURE [PLASTIC BODY PARTS]

09-80E–6

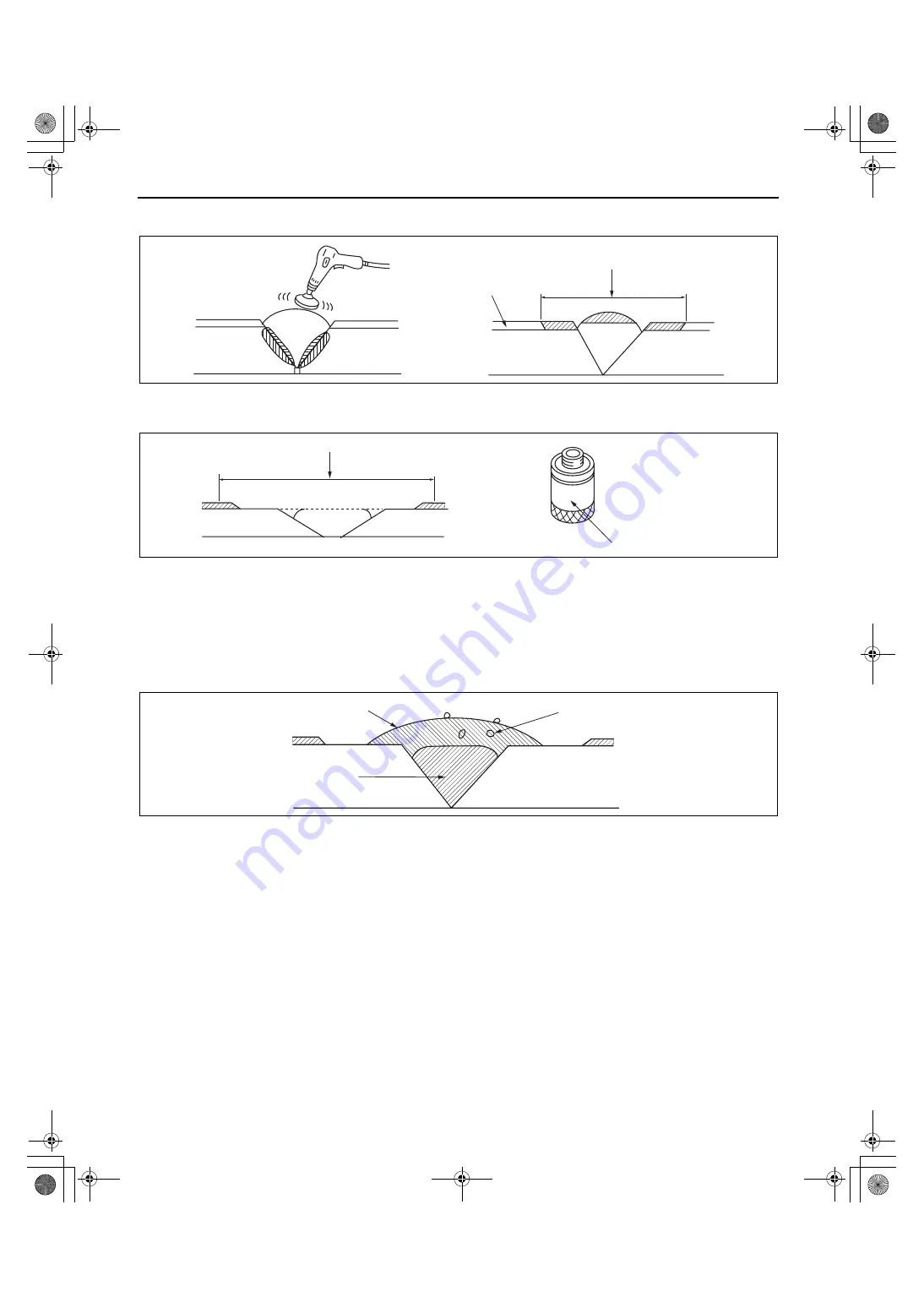

4. Sand the surface of the polypropylene gradually as it is easily melted by the abrasion heat. Sand the area to

which repair agent will be applied.

5. Uniformly apply polypropylene primer with a brush to an area larger than the repaired area. Allow to dry about

10 minutes at 20 °C {68 °F}.

6. Mix the main agent and the stiffening agent in a ratio of one to one. Apply the mixed repair agent to the

damaged area.

Note

•

When mixing the main and stiffening agents, take care not to allow bubbles to form.

•

The repair agent hardens quickly (about 5 minutes); proceed with the work immediately after mixing the

agents.

•

Allow about 30 minutes to dry (20 °C {68 °F}) before sanding.

The repair agent is a two part epoxy adhesive.

When the repair agent hardens, it will provide a good finish with the same flexibility as the polypropylens.

The repair agent for a

urethane

bumper is also a two part adhesive compound. However, this is different from

that for a polypropylene bumper. If the incorrect repair agent is used, the repair will be faulty.

Sand gradually

Sand repair area

Paint

am8rrb00000056

Larger than repaired area

Polypropylene primer

am8rrb00000057

Repair agent

Do not mix air

Weld

Polypropylene surface

am8rrb00000058

3419-1U-06C(09-80E).fm 6 ページ 2006年3月22日 水曜日 午後6時28分