A/C System

Basic Climate Control

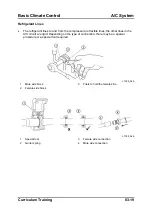

Expansion Valve

•

The expansion valve is the second barrier between the high-pressure and the low-

pressure side of the A/C system (the compressor is the first). The expansion valve

throttles the high-pressure liquid refrigerant, reducing the pressure and the temperature

of the refrigerant. In acting as a restriction in the system the expansion valve allows the

compressor to build up pressure. The expansion valve uses feedback from the

temperature of the gaseous refrigerant exiting the evaporator to control the flow rate of

the refrigerant through the expansion valve. In this way, the heat absorbing performance

of the evaporator is adapted to the actual demand.

Expansion Plotted on the Refrigerant Curve

L1005_023c

X Pressure

Y Temperature

1-2 Compression

4-1 Vaporisation

2-3

Condensation

5

Refrigerant liquid / gas curve

3-4

Expansion

(above is gaseous, below is liquid)

•

The temperature of the refrigerant leaving the evaporator determines how much the ball

valve will open or close. When the refrigerant is cold, the reference pressure will

decrease, making the opening smaller, and reducing the amount of refrigerant passed

on to the evaporator. There will now be less refrigerant in the evaporator to absorb the

heat from the passing air, and the refrigerant temperature will rise.

03-14 Curriculum

Training

Summary of Contents for CT-L1005

Page 1: ...Training Manual Basic Climate Control CT L1005...

Page 20: ...Fundamentals Basic Climate Control Notes 02 14 Curriculum Training...

Page 52: ...A C System Basic Climate Control Notes 03 32 Curriculum Training...

Page 66: ...List of Abbreviations Basic Climate Control Notes 06 2 Curriculum Training...