Copyright 2004 M-B Companies, Inc.

All Rights Reserved

8

Setup and Adjustments

SETUP

Proper setup and leveling of your power broom will

increase the life of the brush and produces more

efficient movement of material. Visually inspect the

adjustments on the broom before each operating

session and measure the adjustments once every 10

hours.

The following procedures must be followed in the

prescribed order in order to be effective.

Once the broom has been properly adjusted, a short

operation period is recommended for break-in;

approximately 15 minutes. After this break-in period

repeat the leveling procedure to ensure that it is correct.

Mounting instructions can be found either in an

installation pamphlet or in the back of this manual.

LEVELING

•

After the broom is mounted to the tractor, loader,

mower, or skid-steer, park the unit on a flat level

surface; preferably concrete or asphalt.

•

If mounting to a skid-steer, lower the arms all the way

down and tilt the quick-attach all the way back.

•

If mounting to a loader, tilt the bucket cylinders all the

way back and lower the arms until the horizontal

mounting shaft is 18” from the ground. If there is a

way to set this location on the loader hydraulics, do

so at this time.

•

If mounting to a mower, set the down limit location so

that the horizontal mounting shaft is as close to 18”

as it can be. Because of the constrained spaces on

some mowers it maybe necessary that the shaft is

higher or lower.

•

*Note* - occasionally the horizontal mounting shaft is

replaced by pins or bolts based on mounting.

•

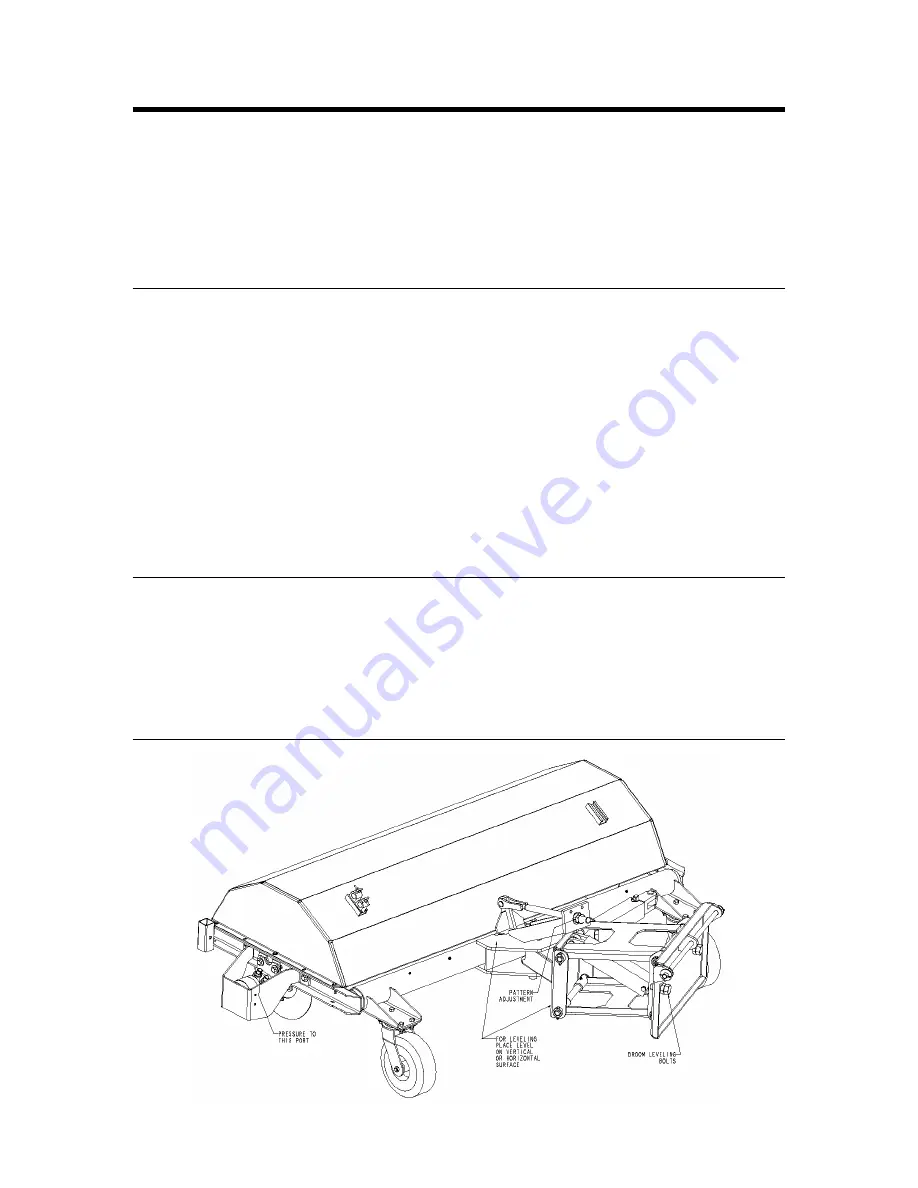

Swing the broom so that it is horizontal and tighten

the pattern adjustment nuts all the way down. (See

Illustration A)

•

Adjust the swing frame so that it are level by adjusting

the bolts in or out on the back of the swing frame.

(Refer to Illustration A) Adjust both bolts evenly to

maintain an even load on the mounting frame and the

arms. Check to see that the frame is level by placing

a small torpedo level vertically on the swing frame or

horizontally on the pivot frame.

•

Recheck for level after any other adjustments,

including pattern adjustment. If the broom is still level

continue to Pattern Adjustment. If not, re-start the

process of leveling.

PATTERN ADJUSTMENT

•

After the broom has been leveled, the last adjustment

is to set the brush pattern. This adjustment is located

at the top of the broom. (Refer to Illustration A)

•

With the unit set-up on a flat level surface adjust the

nuts on the top of the anchor so that the broom has

approximately 3” of contact from the front-most

contact point to the rear-most contact point.

Loosening the nuts will create more pattern.

•

Once this adjustment is set, it can be confirmed by

running the unit for about 30 seconds in the down

position while stationary. Stop the broom and back

the unit away. The ‘cleaned’ portion of the surface

should be 2”-4”.

ILLUSTRATION A