28

5.9 Calling up the Insert / Programmed Insert mode data

(1)

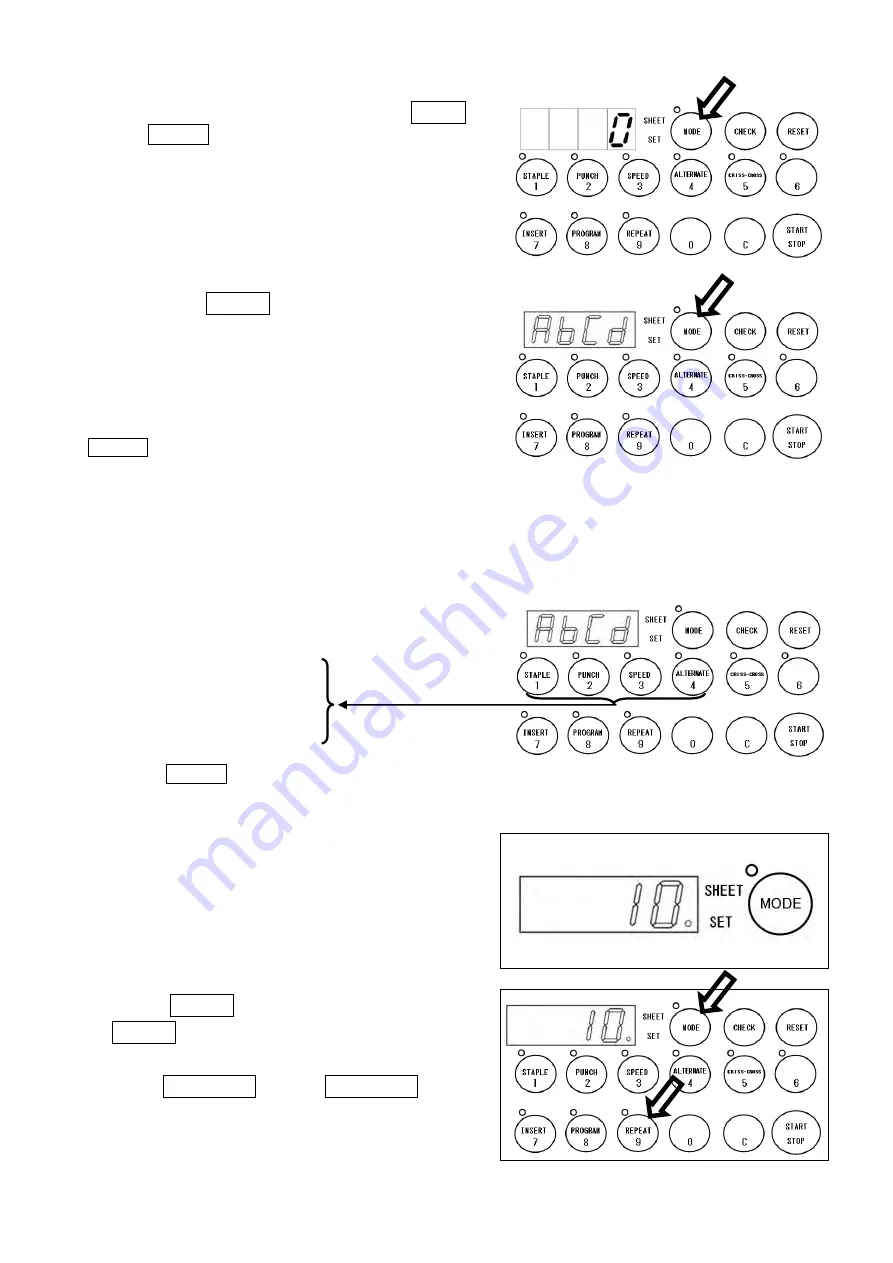

Select Program mode by pressing the MODE key.

( MODE lamp will light)

(2)

Press the MODE key for three seconds; memory

code [AbCd] will be displayed.

-

A flashing letter means that that letter is not stored

in memory.

-

A lit letter means that that letter is already stored in

memory.

Remarks

To check the content of Insert or Programmed

Insert stored memory data directly requires calling

up the data content once.

See 5.6 “Insert mode” and 5.7 “Programmed Insert mode.”

(3)

Press the key to respond to A to d so that the stored

data is indicated on LED display.

Memory code A to d responds to the following

keys:

-Memory code A: Key 1

-Memory code b: Key 2

-Memory code C: Key 3

-Memory code d: Key 4

To return back to the normal collation mode, press

the RESET key.

5.10 Repeat mode

Repeat mode is a function to set Crisscross mode

according to the number of sets, making it easy to file only

part of a chit book.

(1) Program the number of sets to be stacked with

Crisscross stacking.

(2) Press the MODE key to switch to Function mode.

( MODE lamp will light)

(3)Press the REPEAT/9 key; the REPEAT/9 lamp will

light.

Summary of Contents for FC 10 PLUS

Page 2: ...1 ...

Page 11: ...10 2 COMPONENTS 2 1 Overview ...

Page 13: ...12 2 2 Operation Panel ...

Page 39: ...38 ...

Page 40: ...39 ...