34

9. PRODUCT SPECIFICATIONS

9.1 Specifications

Stations

10 stations

Paper Feed

Roller separator system

Station Capacity

1.1" (approx. 350 sheets of 64g/m

2

paper)

Paper Transport

Belt roller system

Stacking Capacity

2.6" (approx. 880 sheets of 64 g/m

2

paper)

Paper Stacking System

Right and left index system (20° apart) or straight stacking

Speed

40-60 set/minute (8.5" x 11" size paper) selectable

Max. paper Size

12.9" x 18.5"

Min. paper size

3.8" x 5.9"

Paper quality

1st and 10th station: 35 to 210 g/m

2

2nd to 9th station: 35 to 160 g/m2

Detection of Station in use

Stations in use can be checked by trial feed programmed by CHECK key.

Detection of Paper Quality

Paper thickness on each station can be checked by trial feed programmed by CHECK key.

Feed Error Detection

Empty feed, no paper, paper jam, double feed (detection of paper thickness with

photo-electric sensors)

Other Detection

Stacking table full, paper eject jam, back door open/close status, (Staple cartridge empty and

paper jam detection when optional stapler-puncher is mounted).

Additional Features

- Automatic elevation of paper feed table

- Alternate collation (Neighboring two stations can be used together for the same

sheet/page.

- Insertion of partitioning paper (according to the designated set)

- Programmed insertion of cover paper (loading covers on the top station and back covers

on the bottom: Good for collation for system-notebook, chits, etc.)

- Three levels of paper feed pressure (four levels for Station 1 and 10, and three levels for

Station 2 to 9)

- Three levels of separator pressure (Fourth level built-in while not displayed on the tablet:

Used for special papers)

- Four-digit display on the operation panel counter, addition/subtraction (preset)

switch-enabled

Power Supply Voltage

AC120V

60Hz

Power Consumption

200W

Dimensions

21.5"W x 29.6"D x 41.6"H

Weight

167.5 lbs

Specifications are subject to change without prior notice for the sake of improvement.

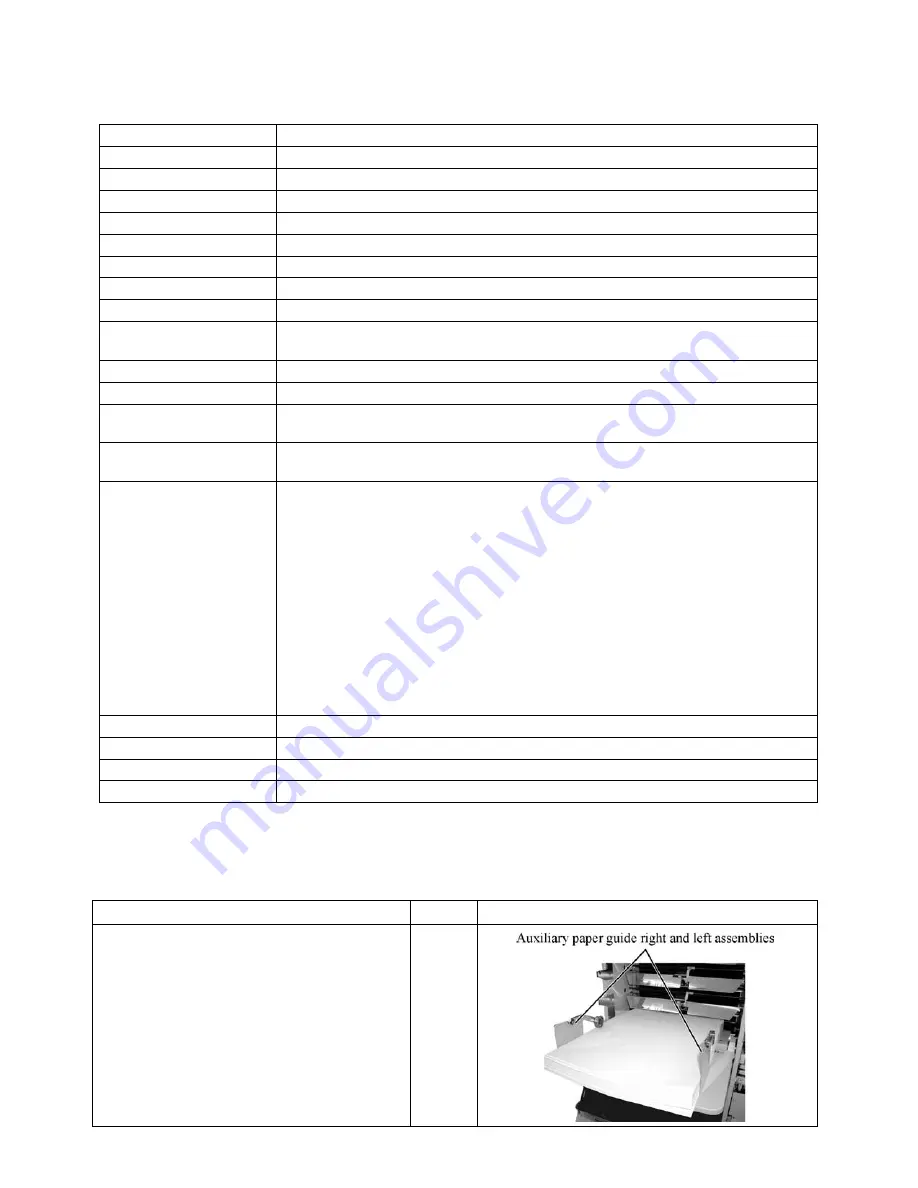

9.2 Optional

parts

Part Name

Qty

Figure

Auxiliary paper guide right assembly

Auxiliary paper guide left assembly

10

each