Sprint5000HCS-USA.doc3.doc Page

12

01/05/2002

5. BOOKLET

MAKING.

1.

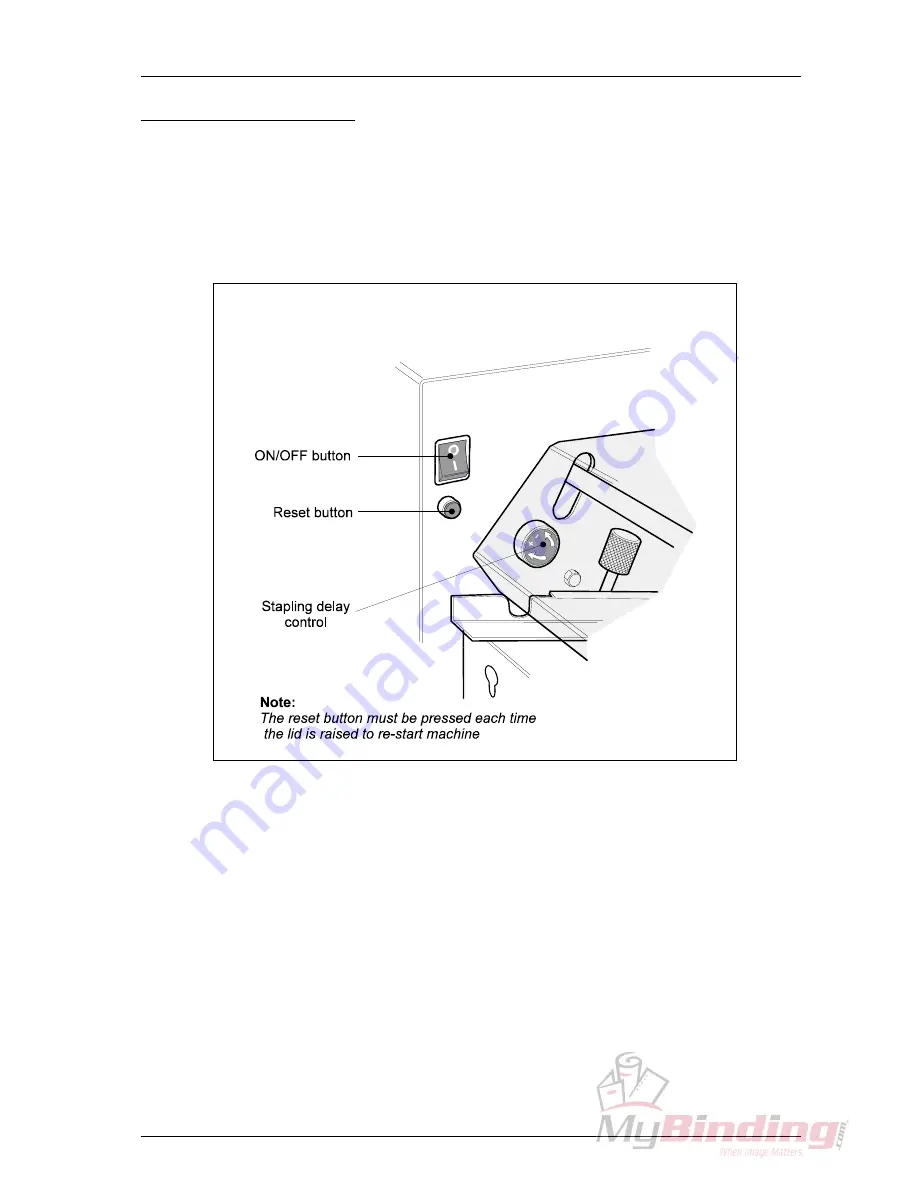

The machine will not operate with the top safety cover in the raised position. After closing the

top safety cover it is necessary to press the circuit reset button, located in the left hand inside

side wall. This is an added safety feature and the machine will not cycle until the button is

pressed.

Figure 8 - Operating controls

2.

When the machine is switched on the motor will not start until the first set of paper is placed in

the machine. If it is left running and not used for a period of more than three minutes the

motor will automatically switch off. The motor will re-start when paper is placed in the

machine.

3.

The stapling / folding operation is started when sensors detect the paper in the machine. The

time between the paper entering the machine and the stapling action can be varied. This is

achieved by turning the Stapling Delay Control shown in figure 8 clockwise for more time and

anti-clockwise for less. When first using the machine, give the Stapling Delay Control a

quarter turn clockwise. This will give time for the operator to settle the paper between the

guides before the machine cycles.