2

PUMP COMPONENTS

13

SHUTDOWN AND CARE

1.-

2.-

3.-

4.-

5.-

6.-

7.-

8.-

9.-

10.-

11.-

12.-

13.-

Pressure regulator.

Ref: 100.610.00

On / Off switch.

Ref: CEA.026

Pressure drain valve.

Ref: 100.420.00

Suction pipe.

Ref: 102.300.00

Displacement pump.

Ref: 102.200.00

Check that the product doesn’t leak.

Put a drop of oil.

Trasmitting pressure.

Ref: 100.410.00

Pressure control assy.

Ref: 102.600.00

Strainer.

Ref: D.910.00

Paint outlet.

Ref: G.100.06

Wire.

Ref: 102.630.00

Troley.

Ref: 102.500.00

Gun.

Ref: J.600.00

*

*

*

Check the packing nut daily. First follow the Pressure Relief Procedure. Be

sure the packing nut is 1/3 full of Oilpack at all times to help prevent fluid

buildup on the piston rod and premature wear of packings.

Clean the fluid filter often and wherenever the sprayer is stored. First follow the

Pressure relief procedure.

Flush the sprayer at the end of each work day and fill it with mineral spirits to

help prevent pump corrosion and freezing.

100-150

200-250

300-350

100-150

200-250

300-350

100-150

200-250

300-350

100-150

200-250

300-350

100-150

200-250

300-350

100-150

200-250

300-350

.021’’

21.20

21.40

21.60

.023’’

23.20

23.40

23.60

.025’’

25.20

25.40

25.60

.027’’

27.20

27.40

27.60

.029’’

29.20

29.40

29.60

.031’’

31.20

31.40

31.60

0.30

0.45

0.64

0.87

1.13

1.36

1.74

2.08

2.49

2.91

3.33

3.86

100-150

200-250

300-350

100-150

200-250

300-350

100-150

200-250

300-350

100-150

200-250

300-350

100-150

200-250

300-350

100-150

200-250

300-350

.009’’

9.20

9.40

9.60

.011’’

11.20

11.40

11.60

.013’’

13.20

13.40

13.60

.015’’

15.20

15.40

15.60

.017’’

17.20

17.40

17.60

.019’’

19.20

19.40

19.60

0

.4

8

M

M

.

0

.4

3

M

M

.

0

.3

8

M

M

.

0

.3

3

M

M

.

0

.2

8

M

M

.

0

.2

3

M

M

.

0

.7

9

M

M

.

0

.7

4

M

M

.

0

.6

8

M

M

.

0

.6

3

M

M

.

0

.5

8

M

M

.

0

.5

3

M

M

.

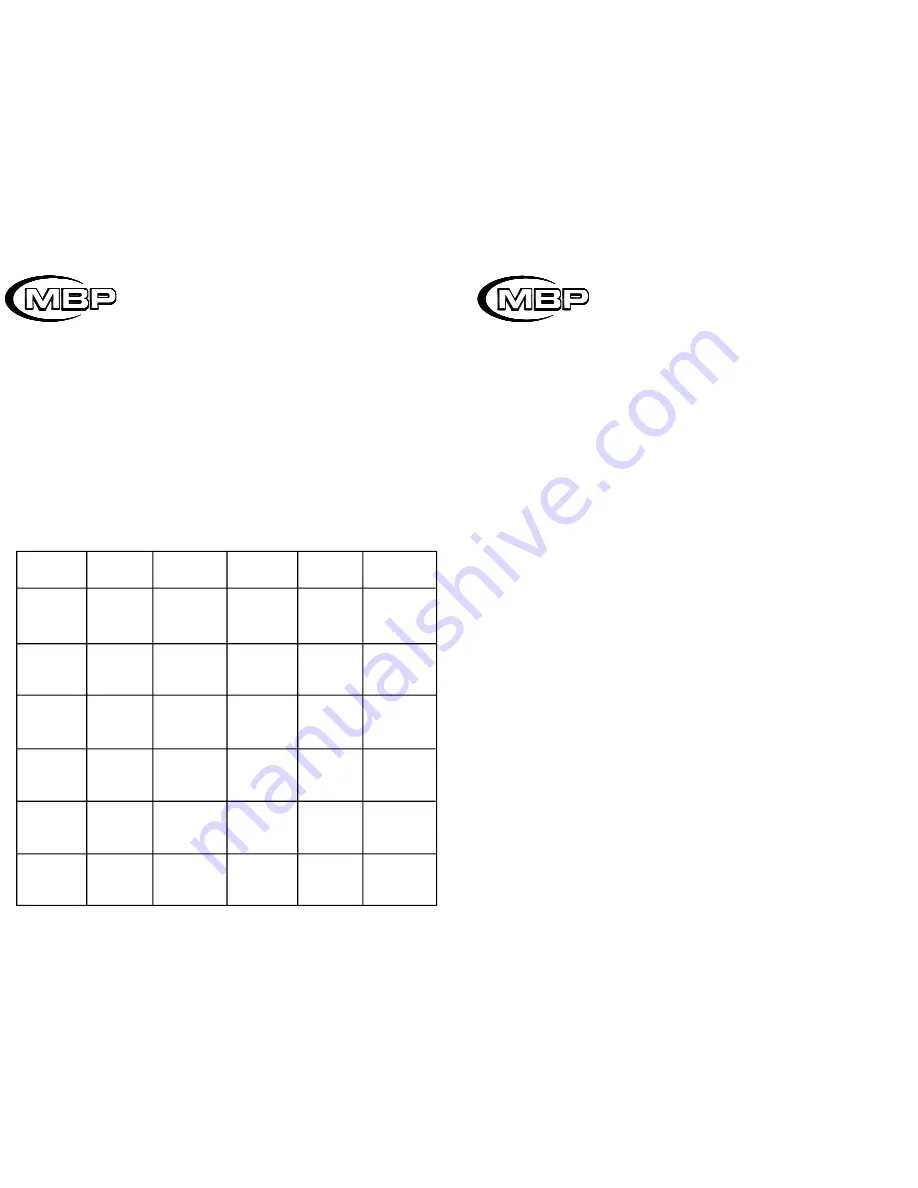

ORIFICE SIZE

MM/INCHES

FLOW IN

LITRES/MIN

FAN WIDTH AT

300 MM.

ORIFICE SIZE

MM/INCHES

FLOW IN

LITRES/MIN

FAN WIDTH AT

300 MM.

STANDARD SPRAY TIPS