8

19

18

21

1

5

15

17

4

25

27

28

28

20

7

15

12

2

11

9

6

23

24

22

3

26

ATTENTION

This equipment generates very high fluid pressure. High pressure spray can cause

serious injury. Read and understand all instructions before operating.

Never point the spray gun at anyone or at any part of the body.

Never put hand, fingers over the spray tip.

Always have the tip guard in place on the spray gun while spraying.

High pressure fluid in the hoses can be very dangerous. If the hose develops a

leak, split or rupture due to any kind of wear, damage or misuse, the high pressure

spray emitted from it can cause a fluid injection injury or other serious bodily injury

or properly damage.

Never use a damaged hose

Tighten all fluid connections securely before each use. High pressure fluid can

dislodge a loose coupling or allow high pressure spray to be emitted from the

coupling.

Proper hose grounding continuity is essential to maintaining a grounded spray

system.

If any fluid appears to penetrate your skin, get emergency medical care at once.

Do not treat as a simple cut. Tell the doctor exactly what fluid was injected.

All chemicals used in the pump must be compatible with the wetted parts of the

pump.

PRESSURE HAZARD

This pump can develope 240 bar working pressure. Be sure that all spray

equipment and accesories used are rated to withstand this pressure. Do not

exceed the maximum working pressure of any component or accessory used in

the system.

SAFETY WARNINGS

3

12

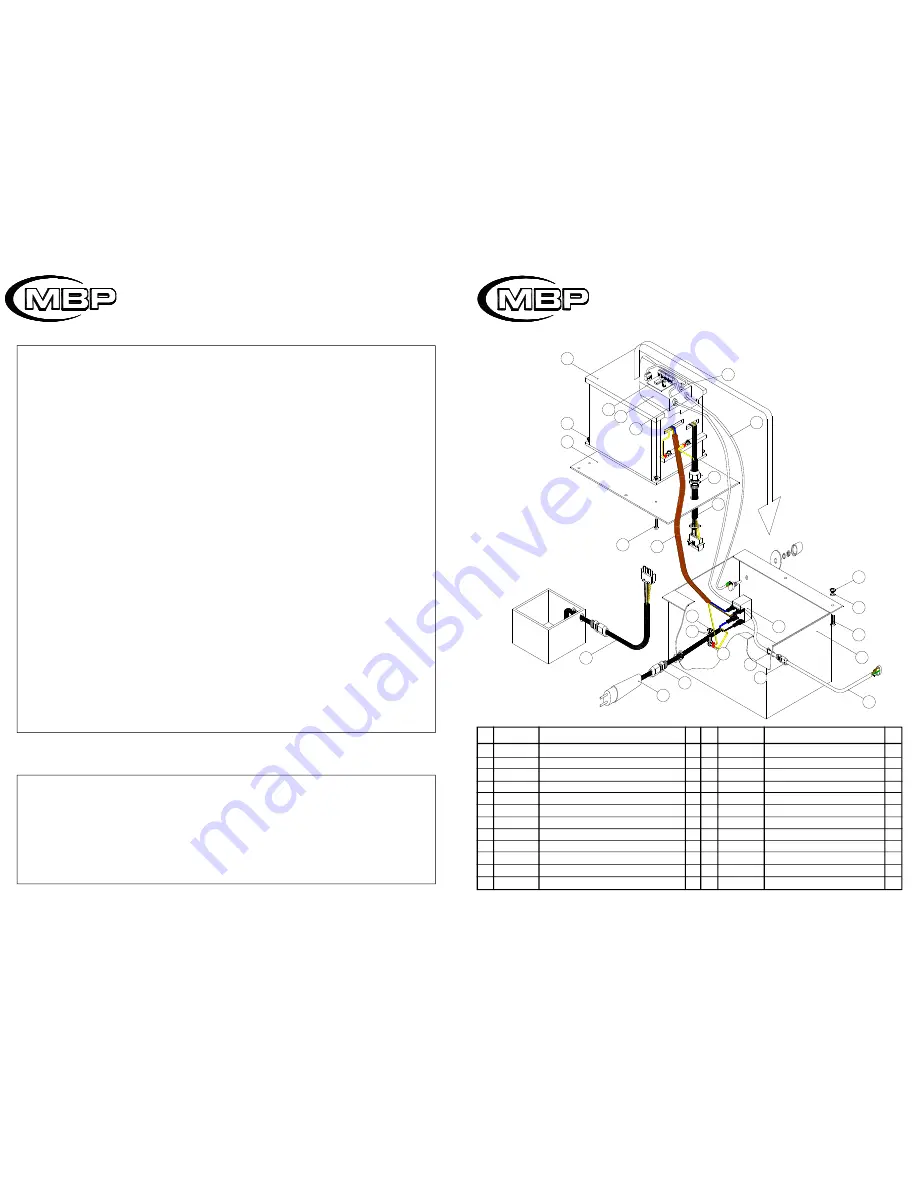

PRESSURE CONTROL ASSY

Nº

REF.

DESCRIPTION

Q Nº

REF.

DESCRIPTION

Q

CEA.026

CEA.027

CEA.030

100.660.00

100.411.00

CEA.037

F.900.20

100.600.03

CAR.022

100.650.00

CTU.105

CTB.013

ON/OFF SWITCH

CONNECTOR

NUT

MOTOR CABLE

PRESSURE TRANSMITTER C.

CONTROL CAR

CONNECTOR

BOX

WASHER

CONTROL CAR INVERTER C.

NUT

SCREW

102.600.01

102.600.02

CEA.041

100.610.00

100.640.00

100.620.00

100.630.00

CTB.005

CAR.254

CTJ.005

CTU.015

CEA.034

BOX

COVER

FRECUENCY INVERTER

PRESSURE REGULATOR

INVERTER OUTLET CABLE

INVERTER ON/OFF SWITCH CABLE

WIRE

SCREW

WASHER

SCREW

NUT

CONNECTOR

1

1

1

1

1

1

3

1

4

1

5

4

1

1

1

1

1

1

1

1

2

2

2

2

1

2

3

4

5

6

7

8

9

11

12

15

17

18

19

20

21

22

23

24

25

26

27

28