COM

LI 1

0

1

L3

MOTOR

PE

W

U

V

PE

220 V 50 Hz.

BROWN

BLUE

BROWN

BLUE

FREQUENCY

INVERTER

GREY

GREEN

WHITE

BROWN

PRESSURE

REGULATOR

GREY

BROWN

YELLOW

GREEN

WHITE

PRESSURE

TRANSMITTER

L1

COM

1

2

+24

4

+24

3

COM

5

6

7

COM

8

LI 1

10

9

1

2

3

4

4

3

2

COM

1

2

+24

4

+24

3

COM

5

6

7

COM

8

LI 1

10

9

1

1

2

3

3

2

1

+24

4

SAFETY WARNINGS

11

PRESSURE RELIEF PROCEDURE

To reduce the risk of serious bodily injury, including fluid injection, splashing fluid

or solvent in the eyes or on the skin, or injury from moving parts or electric shock,

allways follow this procedure whenever you shut off the sprayer, when checking

or servicing any part of the spray system, when installing, cleaning or changing

spray tips, and whenever you stop spraying:

· Engage the gun safety latch

· Turn the ON/OFF switch to OFF (red)

· Unplug the power supply cord (No. 14)

· Disengage the gun safety latch. Hold a metal part of the gun to the side of a

grounded metal pail, and trigger the gun to relieve pressure.

· Engage the gun safety latch

· Open the pressure drain valve (No. 3), having a container ready to catch the

drainage

FIRE OR EXPLOSION HAZARD

Static electricity is created by the flow of fluid through the pump and hose. If every

part of the spray equipment is not properly grounded, sparking may occur and the

system may become hazardous. Sparking may also occur when plugging in or

unplugging a power supply cord. Sparks can ignite fumes from solvents and the

fluid being sprayed, dust particles, whether you are spraying indoors or outdoors,

and can cause a fire or explosion.

If you experience any static sparking or even a slight shock while using the

equipment, stop spraying immediately. Check the system for proper grounding.

Do not use the system again until the problem has been identified and corrected.

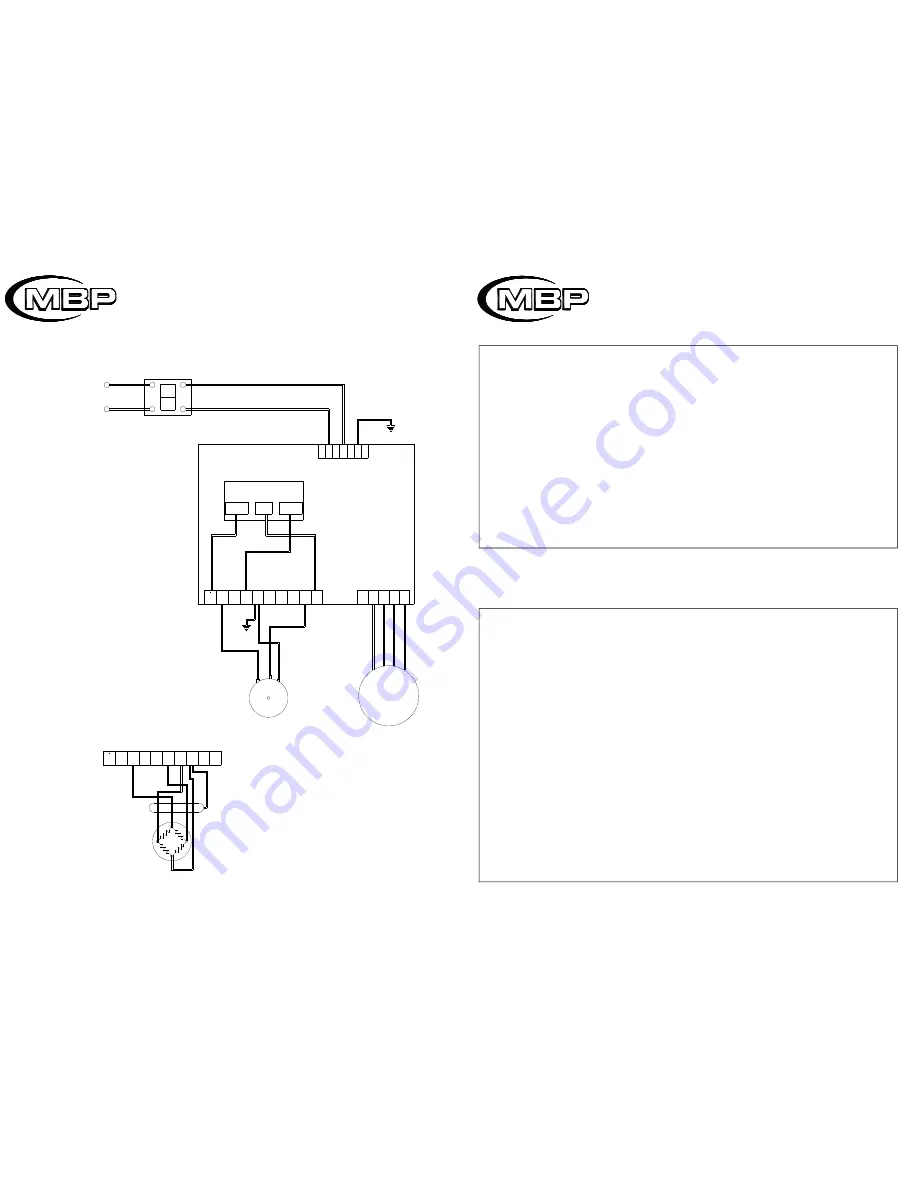

WIRING DIAGRAM