1

3

5

7

4

6

8

20

24

9

21

22

10

10

11

11

12

13

14

15

16

17

18

19

32

34

33

35

36

31

30

29

23

25

28

26

27

37

38

OPERATION

5

10

1.-

2.-

3.-

4.-

5.-

6.-

7.-

8.-

9.-

10.-

Connect hose and gun (use two wrenches to tighten the fittings). Don´t install the

spray tip yet.

Check the electrical service. Be sure the electrical installation is properly rated for

the sprayer and that the outlet you use is properly grounded. Use an extension cord

which has 3 wires of a minimum 4 mm size, and a maximum of 45 m long. Longer

lengths may affect sprayer performance.

Prepare the paint. Stir the paint to mix pigments. Strain the paint to remove particles

that could clog the filters or spray tip.

Put the suction tube into the pail container.

Lower the pressure setting by turning the pressure adjusting knob all the way

counterclockwise

Disengage the gun safety latch.

To prime the pump, hold a metal part of the gun firmly into a metal waste container.

Squeeze the trigger and hold it open, turn the ON/OFF switch to ON, and slowly

increase the pressure setting until the sprayer starts. Keep the gun triggered until all

air is forced out of the system and the paint flows freely from the gun. Release the

trigger and engage the gun safety latch.

Note:

If the pump is hard to prime, place a container under the pressure drain

valve and open it. When fluid comes from the valve, close it. Then disengage the

gun safety latch and proceed as in point 7.

Check all fluid connections for leaks. If any are found, follow the pressure relief,

before tightening connections.

Install the spray tip and tip guard. Be sure the gun safety latch is engaged.

Note:

your new sprayer was factory tested in lightweight oil which was left in to

protect pump parts. before using water-base paint, flush with mineral spirits followed

by clean water. Before using oil-case paint, flush with mineral spirits only.

Fill the packing nut with MBP - Packoil

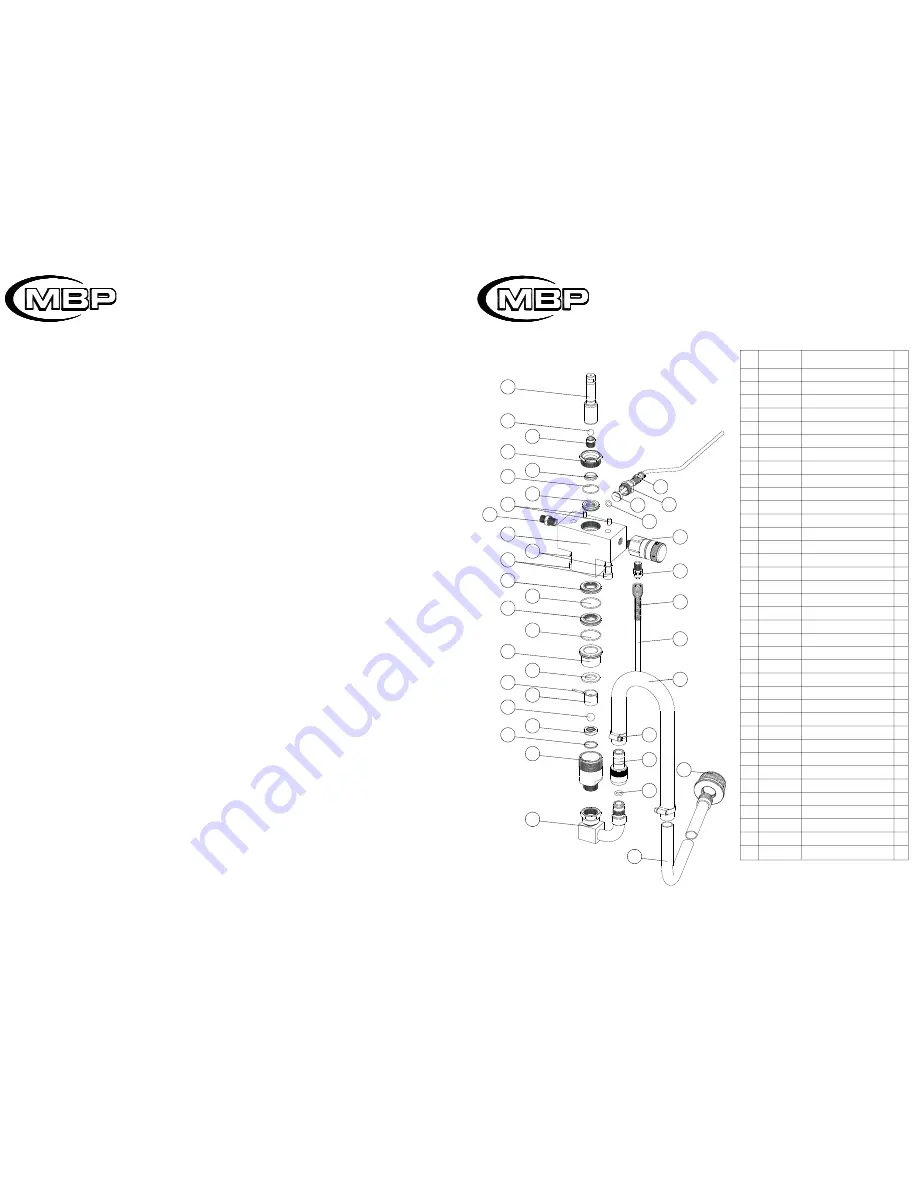

PART LIST DISPLACEMENT PUMP

REF.

102.210.00

CB0.110

080.230.00

102.200.03

102.200.04

CJT.044

102.200.05

102.200.01

102.200.06

CJT.045

102.200.07

102.200.08

080.200.10

080.200.11

CB0.111

102.220.00

102.200.09

102.200.02

CPA.218

CTB.036

CAR053

100.420.00

G.100.06

CJT.164

100.410.01

CEA.027

100.411.00

CNA.057

G.920.03

MAPM.203

102.310.00

CJT.175

102.300.01

CC0001

MAPM.202

102.320.00

D.910.00

DESCRIPTION

Rod

Ball

Seat ball

Tapón

Sleeve

O-ring

Packings

Body

Packings

O-ring

Sleeve

Joint

Sleeve-guide

Pin

Ball

Seat

Joint

Valve housing

Pin

Screw

Washer

Valve

Nipple

Joint

Body

Packing nut

Sensor

Nipple

Spring

Tube

Suction

Joint

Nipple

Clamp

Hose

Tube

Strainer

Nº

1

*3

4

5

6

*7

*8

9

*10

*11

12

13

14

15

*16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

*

KIT 043:

Includes packings (up &

down) packing glands and balls.

Q

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1